What exactly is a carbon brush and what does it do?

You will find that when you buy a power tool, some products will send 2 small accessories in the box, some people know it is a carbon brush, some people neither know what it is called nor know how to use.

And now whether it is a poster publicity or sales introduction, power tools are brushless motor as a major selling point, if you ask what is the difference, many people only know the difference is that there is no carbon brush, then the carbon brush in the end what is it, what is the role of brush motors and brushless motors, what is the difference between le?

Carbon brushes people also call it brushes, mainly in the electrical equipment widely used, is in some motor or generator fixed part and rotating part of the signal or energy transfer, the shape of the rectangular, there are metal wires installed in the spring, carbon brushes is a sliding contact parts, so easy to wear and tear need to be replaced and cleaned up regularly wear off the carbon deposits.

The main component of carbon brush is carbon, when working through the spring pressure like a brush on the rotating parts work, so it is called carbon brush, the main material is graphite.

First understand the main material of carbon brush graphite, graphite belongs to the natural elements, its main component is carbon, black in color, opaque, with a semi-metallic luster, hardness is not high, with the fingernail can be gouged, graphite and diamonds are all carbon, but the nature of the nature of a great difference, this is due to the arrangement of carbon atoms of the structure of the different caused by. Graphite although the composition of carbon, but it is a high temperature materials, its melting point reaches 3652 ℃, the use of this high temperature characteristics, graphite can be processed into high temperature resistant chemical apparatus crucible.

Graphite's conductivity is very good, more than many metals, non-metallic hundreds of times, so the manufacture of electrodes, carbon brushes and other conductive parts; graphite's internal structure determines that it has a good lubrication, we often put in the rusty door locks into the pencil ash or graphite, so that open the door will be much easier, which should be the lubrication role played by graphite it.

Do not think that graphite can only do pencil lead these basic products, now from the graphite extracted from the new material graphene, you must have heard of it, it has become a hot new technology materials, now a lot of high-tech products have to use it.

Carbon brushes are generally used on DC appliances, like the refrigerators, washing machines and air conditioners we use at home don't have brushes, this is because AC motors don't need a constant magnetic field, so they don't need a commutator, and they don't need carbon brushes.

To understand the role and significance of carbon brushes, it is necessary to first understand the working principle and difference between brushed and brushless motors.

Brushed motors

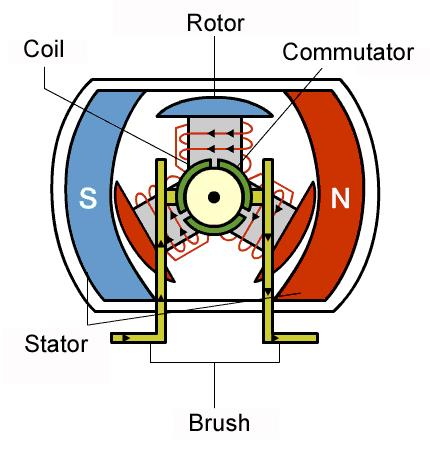

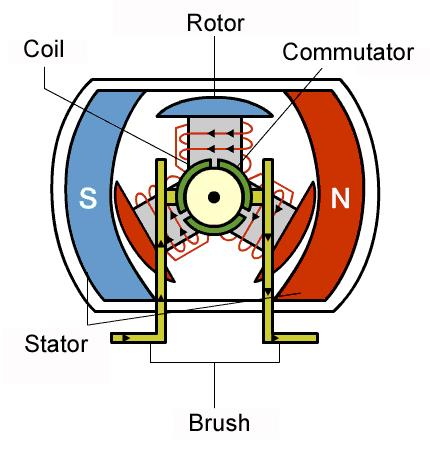

All motors are composed of stator and rotor, in the DC motor, in order to let the rotor turn up, need to constantly change the direction of the current, otherwise the rotor can only turn half a circle, which is like pedaling bicycle pedals, one foot can only pedal half a circle, so the DC motor needs to change the current in the rotor, that is, the direction of the conductor of the energized conductor is reversed when the need to change direction.

The commutation of the commutator is that when an energized conductor is put into an electromagnetic field to cut off the magnetic field, the conductor will be pushed out of the stationary magnetic field by force, this is because the magnetic field's magnetic lines of force are deformed by the electromagnetic field around the conductor, the magnetic lines of force try to bounce back to a straight line shape, and this is equivalent to the attraction and repulsion that will be generated to make the motor turn.

The commutator consists of two semi-circular segments, the connection is separated by insulating material, the two segments of the commutator rotation are connected to the carbon brushes respectively, the carbon brushes will be repeatedly connected to the commutator of the segment that meets the propulsion, so that the repetitive motor is turned.

Brushless motor

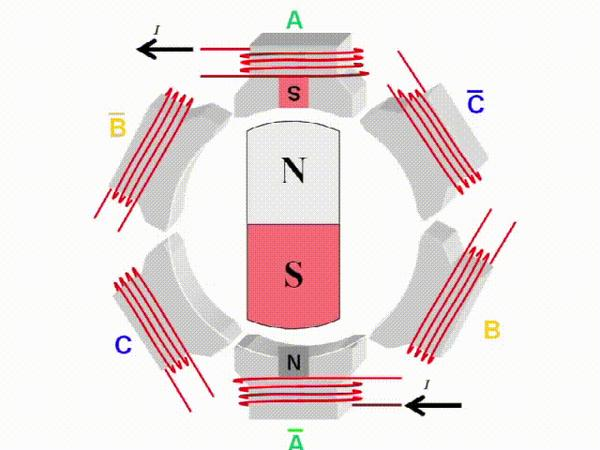

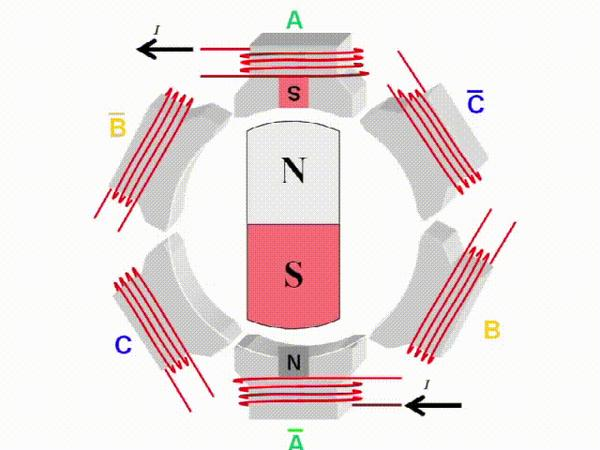

Brushless DC motors are electronically commutated, without commutator and carbon brushes, but using position sensors, mainly composed of permanent magnet rotor, multi-pole winding stator and position sensors, etc. The position sensors are based on the rotor's position magnetic poles to the neighboring stator.

Brush motors are mechanically commutated, the external magnetic poles do not move the internal coil moves, when the motor is working, the commutator and the coil rotate together, the carbon brushes and magnets are not moving, so the commutator and the carbon brushes produce friction to complete the current direction switching.

In the brush motor, the groups of coils lined up in a circular shape, and insulating material between each other and separated, forming a cylindrical and motor shaft into one, the power supply through the two carbon brushes, under the pressure of the spring pressed on the coils, each group of coils rotating to the carbon brushes under the coil can be energized to the group of coils.

As the motor rotates, energize different coils or different two levels of the same coil, so that the coil produces a magnetic field two poles and two poles near the stator of the permanent magnet have an angle, through the same pole repulsion and opposite pole attraction to generate power to drive the motor to rotate.

The difference between brushed motor and brushless motor in addition to carbon brushes, brushed motor is the use of gears to control, which will allow the motor to increase the rate of repair; and brushless motor does not require the use of gears, will not be often repaired, the service life will be a little higher, the reliability is also higher, but the cost of the control system of the brushless motor will also be relatively brush motor high; in addition to brushed motor noise is relatively large, while the brushless motor sound In addition, brush motors are noisy, while brushless motors are much smaller, and the working efficiency will be higher. Carbon brushes play a very important role in DC motors, carbon brushes in the motor between the moving parts of the conductive current, this conduction is a kind of sliding conduction, can be passed from the fixed end of the current to the rotating part of the generator or motor, by several carbon brushes to form a carbon frame, so this way of conduction also causes the carbon brushes are easy to wear out, carbon brushes also have a change in the direction of the current, that is to say, commutation role.

Carbon brushes are also used in alternating current equipment, alternating current motor carbon brushes and direct current motor carbon brushes are the same shape and material, alternating current motors in the wire-wound rotor and the need for variable speeds, before the need for carbon brushes, such as our commonly used hand drills, polishing machines also need to change the carbon brushes, its role is also very important.

As brushless motors have many advantages, especially some power tools and electric bicycles, etc., now on the market with brushless motor products more and more, are discussing the era of carbon brushes will be the end of the brushed motor will be eliminated, this point of view how do you think?