In the current era of rapid technological development, motor equipment technology is undergoing a series of remarkable changes.

1、 The trend towards high efficiency and energy conservation

With the increasing prominence of energy issues, efficient and energy-saving motor equipment is an important development direction. The new motor design optimizes the electromagnetic structure to reduce energy loss. For example, using high-performance magnetic materials such as rare earth permanent magnet materials can significantly increase the magnetic flux density of the motor, thereby improving energy conversion efficiency. Meanwhile, improved motor control algorithms such as vector control and direct torque control can accurately adjust the input power of the motor according to the load situation, avoiding unnecessary energy waste. The efficiency of some advanced industrial motors has reached over 90%, which is significantly more energy-efficient than traditional motors. This not only reduces the operating costs of enterprises, but also conforms to the concept of global green energy development.

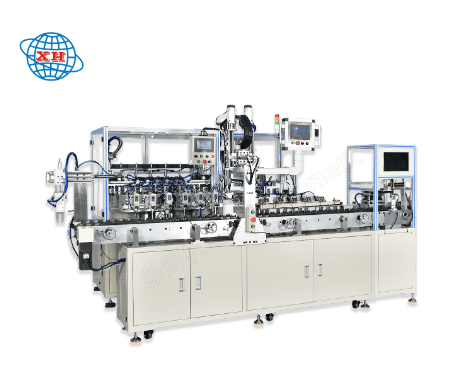

2、 Miniaturization and integration

The increasing demand for space in today's devices has prompted the development of motor equipment towards miniaturization and integration. Through the use of Micro Electro Mechanical Systems (MEMS) technology and advanced manufacturing processes, the size of motors can be significantly reduced. For example, in some fields of micro robots and medical devices, the diameter of micro motors can be reduced to the millimeter level. Moreover, these small motors often integrate various functional components such as sensors and controllers. Taking the motor in a smartwatch as an example, it integrates vibration feedback function, which can provide appropriate tactile feedback when receiving notifications. At the same time, it is compact in size and does not take up too much of the limited space inside the watch.

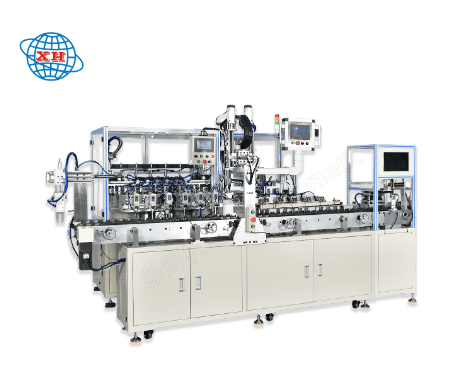

3、 Intelligence and automation

Intelligence is another key trend in motor equipment technology. With the help of Internet of Things (IoT) technology, motors can achieve remote monitoring and fault diagnosis. By installing sensors inside the motor, real-time data such as temperature, vibration, and current can be collected and transmitted to a cloud server for analysis. Once an abnormal situation is detected, the system can promptly issue an alarm and take corresponding protective measures. In addition, adaptive control technology has also been applied in motor equipment, which can automatically adjust the operating parameters of the motor according to changes in load, so that the motor always maintains the optimal working state.

4、 High speed and high-precision control

In some high-end manufacturing and precision instrument fields, higher requirements have been put forward for the speed and control accuracy of motors. For example, in semiconductor manufacturing equipment, motors need to operate stably at extremely high speeds and precisely control their rotation angle and position. To achieve this goal, high-precision encoders and advanced motor drive technologies are widely used. These technologies can improve the speed control accuracy of motors to the micrometer or even nanometer level, ensuring high quality and precision in the production process.