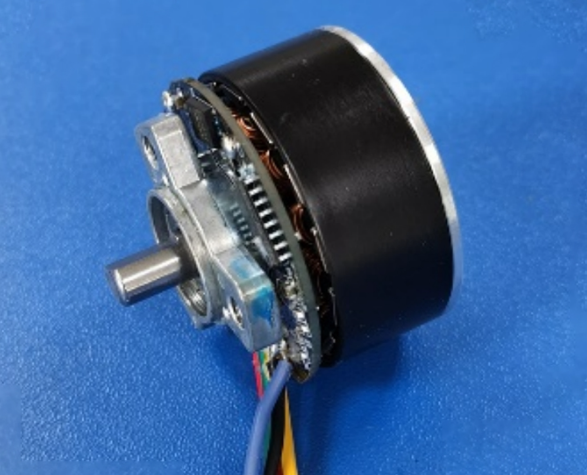

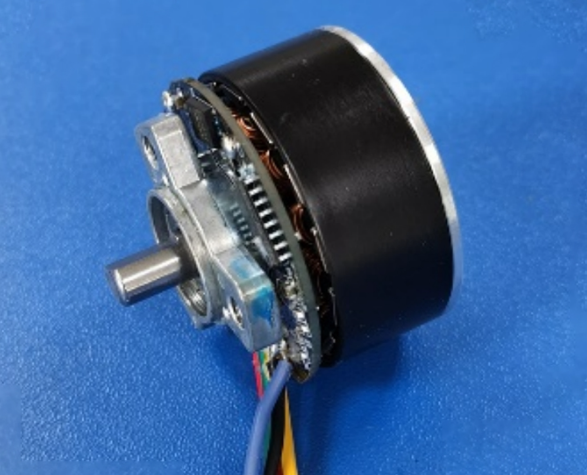

How to analyze and troubleshoot the brushless motor motor automatic rotor reclaimer?

Brushless motor motor automatic rotor reclaimer failure, from mechanical, electrical, pneumatic and other aspects of the analysis and troubleshooting, the following is the specific method:

First, the mechanical part

1、Receiving material is not smooth

Failure analysis: it may be that the receiving track is blocked by foreign objects, or the gap between the rotor and the track is too small, resulting in the rotor is blocked in the conveying process. It is also possible that the position of the receiving tray is inaccurate, unable to properly receive the rotor.

Troubleshooting method: Clean the foreign matter on the receiving track, check and adjust the clearance between the rotor and the track so that it meets the requirements of the equipment. Recalibrate the position of the receiving tray to ensure that it is accurately docked with the conveying track.

2、Mechanical transmission parts abnormal

Failure Analysis: Loose belts, chain wear, gear damage, etc. may lead to mechanical transmission problems, manifested in abnormal noise when the equipment is running, transmission is not smooth or power transmission interruption.

Troubleshooting: Adjust the tension of the belt, replace the chain or gears that are badly worn. Regular lubrication of transmission components to reduce wear and tear, to ensure its normal operation.

Second, the electrical part

1, the motor does not turn

Failure analysis: it may be power failure, such as loose power lines, blown fuses, etc.; it may also be the motor itself is damaged, such as winding short circuit, disconnection, etc.; or drive failure, such as abnormal control signals, power components are damaged.

Remedy: Check whether the power cord is firmly connected, and replace the blown fuse. Use a multimeter and other tools to detect the resistance of the motor winding to determine whether the motor is damaged, and replace the motor if it is damaged. Check the control signals and power components of the drive, repair or replace the faulty drive.

2、Control system failure

Failure analysis: the controller may have program errors, improper parameter settings, input and output signal abnormalities and other problems, resulting in equipment can not run in accordance with the intended logic.

Troubleshooting: Check whether the program of the controller is correct, and make timely corrections if there is any error. Check whether the parameter setting of the equipment is in line with the actual production demand, and adjust the unreasonable parameters. Use professional tools to detect the input and output signals, repair or replace the faulty signal lines or sensors.

Third, the pneumatic part (if any)

1、Insufficient air pressure

Failure Analysis: It may be the air compressor failure, air pressure pipeline leakage, pneumatic components damage and other reasons that lead to air pressure can not meet the operating requirements of the equipment.

Troubleshooting: Check the operating status of the air compressor to ensure that it works properly and outputs sufficient air pressure. Check whether there are leaks in the pneumatic pipeline and repair the leaks in time. Check and maintain the pneumatic components, replace the damaged pneumatic components.

2, pneumatic actuator abnormal action

Failure analysis: such as cylinders, pneumatic fixtures and other components may be stuck, air leakage and other problems, affecting the normal operation of the equipment.

Remedy: Clean and lubricate the cylinder and pneumatic fixture to eliminate the stalling fault. Check whether the seals of the pneumatic actuating elements are damaged, and replace them in time if they are damaged to solve the air leakage problem.

In fault analysis and troubleshooting, maintenance personnel should have certain professional knowledge and skills, in strict accordance with the equipment's operating manual and maintenance specifications. For some complex faults, you may need to use professional testing tools and equipment, if necessary, you can contact the equipment manufacturer's technical support staff for assistance.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool to seek help.