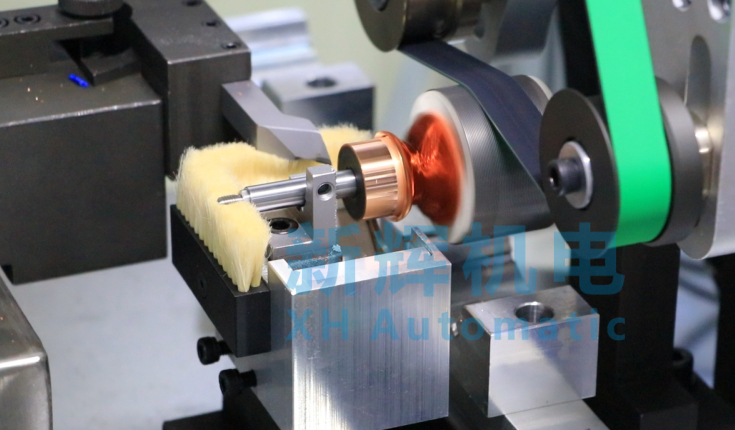

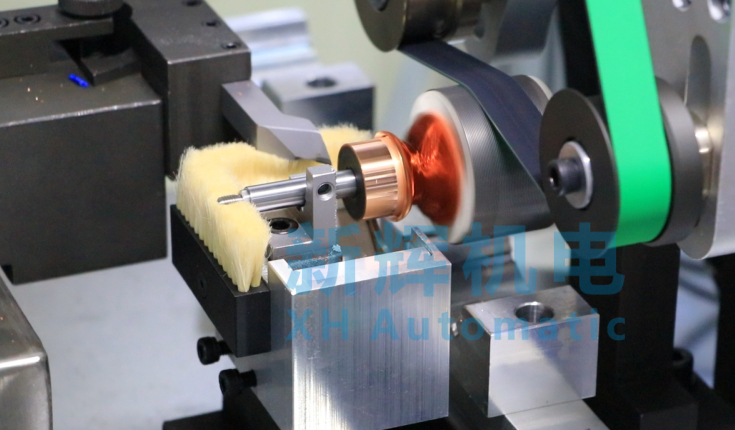

How to troubleshoot and analyze a motor motor rotor automatic single station fine turning machine?

Motor motor rotor automatic single-station fine turning machine for fault analysis and troubleshooting, you can follow the steps below:

1, understand the structure and working principle of the machine: first of all, familiarize yourself with the structure and working principle of the motor motor rotor automatic single-station fine turning machine, including the function of each component and the relationship between each other.

2、Preparation before troubleshooting: Make sure that the machine is in a power-off state, and prepare the necessary tools and testing equipment, such as multimeter, insulation resistance tester, short-circuit detector and so on.

3、Observation and inspection: Observe the outside of the machine for any obvious signs of damage, deformation or abnormal wear and tear. Check that all connecting wires and cables are intact and not loose or damaged.

4, power supply and electrical system check: check whether the power supply voltage is stable and whether the power supply line is normal. Use a multimeter to check whether the electrical connections of the motor and control system are normal, including terminals, relays and contactors.

5、Mechanical parts inspection: Check the wear and damage of key mechanical parts such as collets, guide rails, bearings, gears and screws. Check whether the lubrication system is normal, and make sure that all parts that need lubrication have enough lubricant.

6、Control system check: Check whether the control system such as PLC and touch screen work properly, including input and output signals, program running status. Check whether the sensors and actuators respond correctly, such as position sensors, limit switches and so on.

7, fault code and alarm: check whether the machine has a fault code or alarm information, this information can provide the specific location and cause of the fault.

8, step-by-step elimination method: According to the observed phenomena and fault codes, step-by-step elimination of possible problems until the cause of the failure is found and repaired.

9, software troubleshooting: If the problem involves software, check whether the software is a new version, if not, update. At the same time, check whether the software settings are correct, to ensure that all parameters are in line with production requirements.

10, sensor positioning problems: check whether the sensor is clean, and whether the distance value is set correctly. If the sensor is damaged, it needs to be replaced with a new one.

11, automation control problems: check the hardware connection of the control system to ensure that all connections are firm and reliable. At the same time, check whether there are bugs in the software program, if necessary, software update or reset the system.

12, data transmission problems: check the network connection and data transmission lines to ensure that there is no physical damage or connection problems.

13, user interface problems: restart the operator interface or the entire system, check whether there are software updates need to be installed. If the problem persists, it may be necessary to check the operating system or contact technical support.

Through the above steps, fault analysis and troubleshooting can be carried out systematically to ensure the normal operation and productivity of the motor motor rotor automatic single station fine turning machine. ※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool for help.