What are the spare parts needed and how to set up the guaranteed stock for motor motor rotor manual six-station double flying fork winding machine?

1、Required spare parts

Mechanical parts

l Transmission parts: Belt, chain and gear are common wearing transmission parts. Belt may be worn, loose or even broken after a long time of use; chain may be elongated, chain link wear; gear teeth will have wear and fatigue damage. Damage to these parts will affect the normal transmission of the winding machine, resulting in uneven winding speed or inaccurate movement.

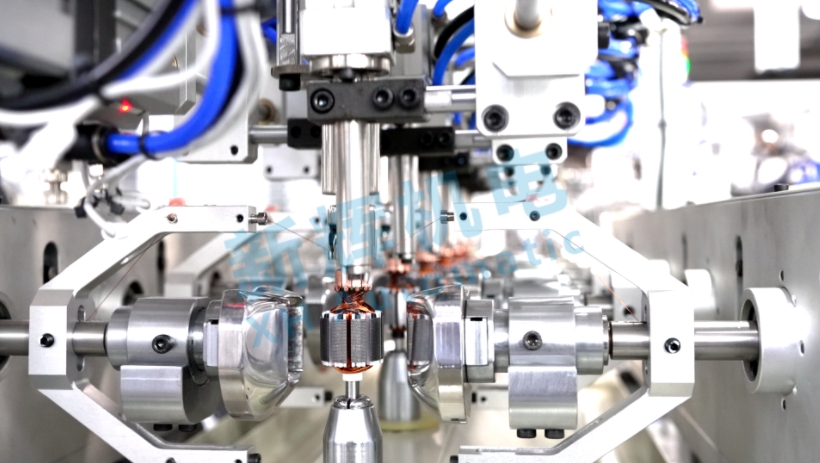

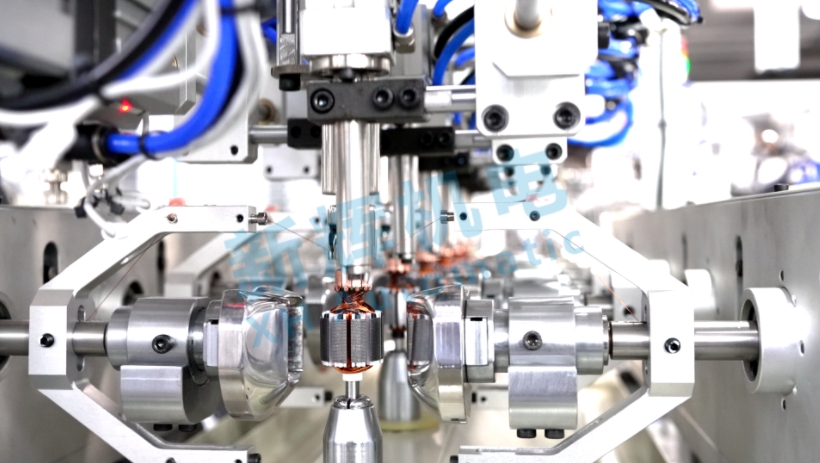

l Flying fork and related parts: The rotating shaft and bearings of the flying fork are easy to wear out, and the wire guiding devices on the flying fork, such as the guide wheel, may be damaged due to the friction of the wire. In addition, the brushes of the driving motor of the flying fork (if it is a brushed motor) also belong to the fragile parts.

l Fixture and indexing mechanism: Parts such as the collets of the fixture and the cams and rollers of the indexing mechanism are subject to wear and tear during frequent opening and closing and indexing motions. Worn fixtures may not be able to clamp the rotor securely, and the accuracy of the indexing mechanism may deteriorate, affecting the accuracy of the winding position.

l Lubrication and seals: Lubricating oil and grease are necessary to ensure the good operation of mechanical parts. Meanwhile, all kinds of seals, such as oil seals and sealing rings, are used to prevent lubricant leakage and external impurities from entering the inside of the parts, and are also spare parts to be stocked.

Electrical Components

l Motors and drives: Motors can be damaged by overloading, short-circuiting or prolonged operation. Motor drives may also fail, such as burned out electronic components or abnormal control signals. Stocking a certain number of motors and drives will allow for timely replacement in the event of a failure and reduce downtime.

l Sensors: Position sensors, tension sensors, counting sensors, etc. may fail in the course of use due to environmental factors (e.g. dust, oil, vibration) or their own aging. These sensors are critical to the precise control of the winding machine, so it is necessary to have a certain number of sensors of the same type.

l Circuit Boards and Electronic Components: Capacitors, resistors, chips and other components on circuit boards can fail. For some easy to damage the general electronic components, such as fuses, electrolytic capacitors, etc., can be properly stocked. In addition, for the special control circuit board of the winding machine, it is better to have spare parts as well.

l Electric wires and cables: Power cables and signal cables may be pulled and worn out during the daily operation of the equipment, and broken or short-circuited. Stock up various sizes of wires and cables for emergency repair and replacement.

Software-related items

l Storage device: used to backup and restore the software program and parameter settings of the winding machine. Such as USB flash disk, portable hard disk, etc., to ensure easy data transmission and storage in case of software problems or need for updating.

2、Methods of safeguarding inventory setting

Evaluation based on failure frequency and maintenance time

l Statistics of historical failure data: Collect the past failure records of the winding machine, including information on the failed parts, frequency of failure, and time required for repair. For example, if it is statistically found that the flying fork bearing fails once every 3 months on average, and it takes 1 day to repair and replace the bearing each time, then the guaranteed stock of the bearing can be set based on this data.

l Consider the priority of critical components: for those critical components that will lead to a long downtime of the winding machine once damaged, such as motor drivers, control circuit boards, etc., a higher guaranteed inventory should be set. And non-critical components, such as some auxiliary seals, can be appropriately reduced inventory level.

Consider the supplier delivery period and supply stability

l Determine the supplier delivery period: Understand the normal delivery time of spare parts suppliers. If the supplier's delivery period is long, for example, a special specification sensor needs to be ordered from abroad with a delivery period of 3 weeks, then the guaranteed stock of this part needs to be increased accordingly to cope with the possible waiting for spare parts.

l Evaluation of supply stability: Evaluate the supplier's supply stability, including whether there will be out-of-stock, product quality is stable and other factors. If the supplier's supply is unstable, it may be necessary to find an alternate supplier or increase the guaranteed stock.

Cost-Benefit Analysis

l Calculate the cost of inventory: Safeguarding inventory will take up a certain amount of capital and storage space. Calculate the cost of inventory, including purchase cost, storage cost (e.g., warehouse rent, custodian fees, etc.), and cost of capital utilization (e.g., interest loss on capital).

l Weighing downtime losses and inventory costs: Consider the production losses caused by the downtime of the winding machine. If a one-day downtime of the winding machine will cause a large economic loss, then it is appropriate to increase the guaranteed inventory to reduce the downtime. Through the cost - benefit analysis, find a balance point, so that the guaranteed inventory can meet the maintenance needs, but also to control the cost within a reasonable range.

Dynamic Adjustment of Safeguarded Inventory

l Regular review and update: Review the operation of the coil winder, the frequency of failures, the supplier situation and other factors on a regular basis (e.g., quarterly or half-yearly), and adjust the quantity and type of guaranteed inventory according to the actual situation. For example, if the failure frequency of a certain component is significantly reduced through equipment upgrading, the guaranteed inventory of that component can be appropriately reduced.

l Considering the change of the intensity of equipment use: If the production task of the winding machine increases, the intensity of use becomes larger, then accordingly it may be necessary to increase the guaranteed inventory of some wearing parts; on the contrary, if the frequency of equipment use is reduced, the inventory can be reduced appropriately.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for help.