What are the contents of pre-service training for employees of the String Excitation Motor Motor Stator Paint Drip Machine?

Stringer motor motor stator paint dripping machine employee pre-training content usually includes the following aspects:

1、Equipment basic knowledge

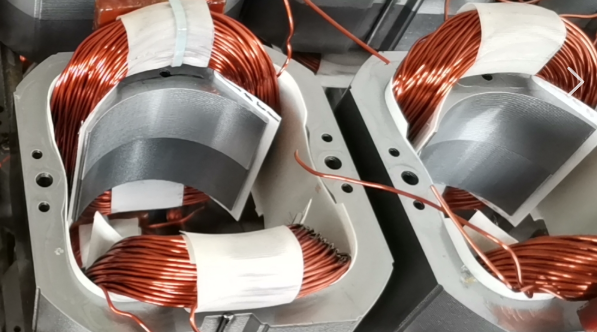

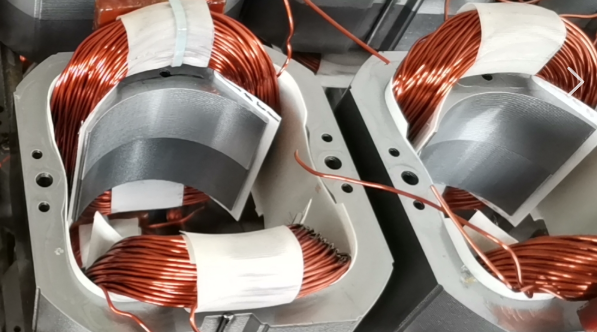

l equipment structure and principle: a detailed introduction to the overall structure of the paint dripping machine, including mechanical components (such as conveying system, paint dripping system, drying system, fixture, etc.) of the composition and function, as well as the electrical control system (such as power supply, controller, sensors, motor drive, etc.) of the principle of operation. Let the staff understand how the various parts of the equipment work together to realize the automated process of stator paint dripping. For example, explain how the paint is conveyed to the nozzle through the pump and pipeline, and then accurately dripped onto the stator, and how the drying system cures the paint through heating and ventilation.

l Equipment Specifications and Parameters: Train employees to familiarize themselves with the key specifications and parameters of the paint dripping machine, such as the speed of paint dripping, the adjustment range of paint dripping volume, the range of drying temperature and time setting, and the range of stator sizes that can be handled. Make the staff understand the importance of these parameters to ensure the quality of paint dripping and production efficiency, and how to make reasonable parameter settings according to different product requirements. For example, for different types of series-excited motor motor stator, the required amount of paint dripping and drying temperature may be different, employees need to know how to accurately adjust the parameters of the equipment according to product specifications.

2、Operation process and standardization

l Preparation before starting: Teach the staff to carry out various inspections and preparations before starting the paint dripping machine, including checking whether there is any damage to the appearance of the equipment, whether the parts are firmly connected, cleaning up the sundries inside the equipment and the working area, checking whether the level, viscosity and quality of the paint are in line with the requirements, confirming whether the power supply, gas supply (if any) is normal, and lubricating the lubricating points of the equipment with necessary lubrication. etc. Ensure that the equipment is in good working condition before startup to avoid equipment failure or production accidents caused by inadequate preparation.

l Normal operation steps: Through practical demonstration and simulated operation, let the employees master the normal operation procedures of the paint dripping machine, such as how to install the stator on the fixture correctly, how to start the equipment and carry out the paint dripping and drying operation in accordance with the pre-determined procedures, including setting up the parameters of the paint dripping, starting the paint pump, controlling the conveying speed, monitoring the drying process, and so on. At the same time, employees are trained how to observe the running status of the equipment during operation, such as whether there is any abnormal vibration, noise, odor or temperature change, etc., as well as how to deal with some common operational problems in time, such as clogging of spray nozzles, uneven paint dripping, etc.

l Shutdown and maintenance operations: teach employees how to properly shut down the paint dripping machine after completing the production tasks, including stopping the paint pump and motor operation, shutting down the power supply and air source, cleaning up the surface of the equipment and the working area of the residual paint and impurities, etc.. In addition, employees should be introduced to the daily maintenance of the equipment, such as regular cleaning of filters, checking the wear and tear of transmission parts, calibrating sensors, etc., as well as how to fill in the equipment operation records and maintenance logs to ensure long-term stable operation and good performance status of the equipment.

3、Precautions

l Electrical precautions: Emphasize the risks of the electrical system of the paint dripping machine, such as the danger of electric shock. Train employees on how to operate the electrical equipment properly, avoid touching the electrical parts with wet hands, understand the location and use of the emergency stop button, and how to cut off the power supply and take appropriate measures in the event of an electrical fault. At the same time, teach employees to regularly check the grounding of electrical equipment to ensure the normal operation of the equipment.

l Chemical precautions: Since paint dripping machines involve the use of lacquer, employees need to understand the chemical properties and potential hazards of lacquer, such as the effects of volatile organic compounds (VOCs) on human health (e.g., respiratory irritation, dizziness, etc.). Employees are trained to wear personal protective equipment (PPE) properly, such as gas masks, protective gloves, goggles, etc., as well as how to clean up and dispose of paint spills or spatters to prevent skin contact and inhalation of the paint mist.

l Mechanical precautions: Introduce the movement characteristics of the mechanical parts of the paint dripping machine and the potential risks of entrapment and collision, e.g. conveyor chains, moving parts of fixtures, etc. Employees are taught to keep a distance during the operation of the equipment to avoid any part of the body coming into contact with the mechanical parts in operation and how to ensure that the mechanical parts are at a standstill and necessary locking measures are taken to prevent accidental start-up when carrying out maintenance and cleaning of the equipment.

l Fire and Explosion Prevention: Lacquer is usually flammable, so employees need to be trained to understand fire and explosion prevention measures, such as strictly prohibiting smoking and the use of open flames around the equipment, maintaining good ventilation in the work area, avoiding lacquer leakage onto hot parts, and familiarizing themselves with the location and use of fire extinguishers and fire-fighting equipment, so as to ensure that they can take quick and effective fire-fighting measures in the event of a fire, and to reduce the loss of the accident. The following are some of the points of quality control

4、Quality control points

l Drip paint quality standards: Define the quality standards and requirements for the drip paint of the stator of the series-excited motor motor, such as the thickness of the paint film, uniformity, adhesion, flatness and other indicators. Let the staff understand the importance of these quality standards for the performance and reliability of the motor, and how to ensure that these quality standards are met or exceeded by adjusting the parameters of the paint dripping machine and operating methods. For example, too thin paint film may lead to insufficient insulation performance, while too thick may affect the heat dissipation performance of the motor, so employees need to know how to accurately control the amount of paint dripping and paint dripping uniformity, in order to get the paint film in line with the quality requirements.

l Quality inspection methods: train the staff to master some basic paint drop quality inspection methods and the use of tools, such as paint film thickness meter, adhesion tester and so on. Teach the staff in the production process how to regularly sample the quality of paint drops for testing, and how to adjust the parameters of the equipment or operating methods according to the test results in a timely manner to ensure the stability and consistency of product quality. At the same time, let the staff understand the feedback and treatment process of quality problems, if found quality problems should be reported to the superiors in time, and assist the quality control personnel to analyze and solve the problem, to prevent the outflow of defective products.

5、Emergency measures

l Common troubleshooting: For some common failures that may occur during the operation of the paint dripping machine, such as motor failure, nozzle clogging, temperature control system failure, paint pump failure, etc., train the staff how to quickly identify the failure phenomenon and master the corresponding emergency treatment methods. Through actual case analysis and simulation troubleshooting training, employees can calmly respond when encountering faults and take effective measures to restore the normal operation of the equipment as soon as possible to reduce the production interruption time. For example, when the motor is abnormally hot or smoking, employees should immediately stop the operation of the equipment and carry out inspection and treatment in accordance with the operating procedures, such as checking the heat dissipation of the motor, whether the power supply is normal or not, and whether the motor winding is short-circuited.

l Emergency Response to Accidents: Develop and train employees to respond to emergency response plans for unexpected accidents, such as fire, leakage, electric shock and other accidents. Let the staff understand how to take action quickly in case of accidents, including immediately activating the emergency stop button, evacuating the people on the scene, extinguishing the fire with fire-fighting equipment, and calling the first aid personnel. At the same time, we organize regular emergency drills for our employees to improve their reaction speed and ability to cope with emergencies and to ensure that they are able to protect themselves and reduce accidental damage to the greatest extent possible in the event of an accident.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.