What are the contents of pre-service training for employees of series excitation motor motor stator winding machine?

Series excitation motor motor stator winding machine employee pre-service training content includes:

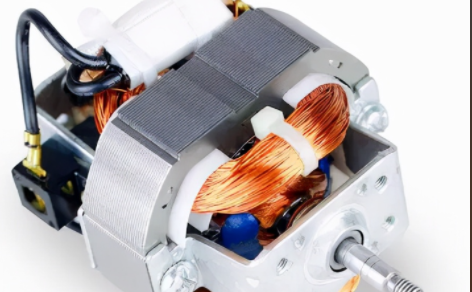

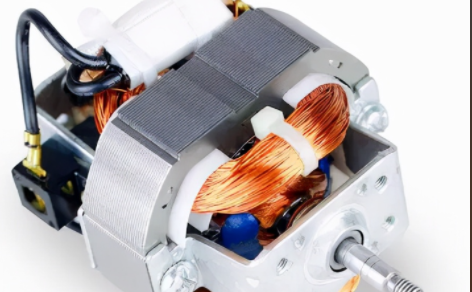

1, the principle and structure of the equipment

l The principle of series-excited motor: explain in detail the basic working principle of series-excited motor, including the flow of current in the stator winding and rotor winding, electromagnetic interaction how to generate rotating torque to drive the motor operation, as well as the characteristics of series-excited motor (e.g., the relationship between rotational speed and torque, the characteristics of rotational speed changes with the load, etc.). Through schematic diagrams, animation or actual motor model display, it helps employees to understand the operation mechanism of the motor and lays a theoretical foundation for the subsequent winding work.

l Mechanical structure of the winding machine: Introduce the structure, function and connection relationship between each component of the winding machine, such as the frame, winding spindle, wire arrangement mechanism, tension adjustment device, transmission system (belt drive, gear drive, etc.), fixture and other components. Let the staff have a clear understanding of the physical structure of the winding machine, and understand how the components work together to complete the stator winding task.

l Electrical control system: explain the electrical control principle of the winding machine, including the working principle and connection of power supply, motor driving circuit, controller (such as PLC, microcontroller, etc.), sensors (such as tension sensor, position sensor, speed sensor, etc.), human-machine interface (HMI) and other parts. Make the staff understand how to realize the automatic operation of the winding process through the electrical control system, such as the adjustment of the winding speed, the precise control of the row of wires, and the stable maintenance of the tension.

2、Operating procedure and standardization

l Preparation before start-up: Teach the staff to check all the equipment before start-up, including checking whether there is any damage to the appearance of the equipment and whether the parts are firmly connected; cleaning up the sundries and dust on the working table to ensure the winding environment is neat and tidy; checking whether the power supply of the electrical system is connected normally and whether the switches and buttons are in the initial position; checking whether the winding molds and clamps are correctly installed and not damaged; lubricating the lubrication points of the equipment, such as the winding spindle, and lubricating the winding machine. Lubricate the lubrication points of the equipment, such as winding spindle bearings, wire guides and other parts, to ensure that all parts can operate normally after the equipment is started.

l Winding operation steps: Demonstrate in detail the specific operation process of winding, such as how to correctly install the stator core in the fixture and fix it; according to the design requirements of the stator winding, set up the winding parameters in the equipment control system, including the number of coils, wire diameter, winding speed, spacing, tension, etc.; install the enameled wires in the wire barrel and guide them to the winding position through the wire crossing device; start the winding machine and observe the winding process to ensure that the enameled wires are in the correct position after the equipment is started. Start the winding machine and observe the winding process to ensure that the enameled wires are evenly and closely wound on the winding spindle, with neat rows of wires and moderate tension; during the winding process, pay attention to the operation status of the equipment at all times, and if there are any abnormalities (e.g. broken wires, skipped wires, abnormal vibration of the equipment, etc.), it should be shut down in time to deal with them.

l Shutdown and cleanup: After completing the winding task, teach the staff the correct shutdown steps, first stop the winding operation, return the winding machine moving parts to the initial position; turn off the power supply of the electrical system, including the controller, motor drive, etc.; clean up the residual threads on the equipment workbench, scraps and other sundries, and carry out a simple cleanup of the equipment, such as wiping the surface of the winding spindle, wire guide, etc.; check whether the various parts of the equipment are in normal condition, in order to provide a better solution to the problem of the winding process. Check whether the parts of the equipment are in normal state, ready for the next start-up.

l Operation norms and precautions: Emphasize the norms and precautions in the operation process, such as strictly prohibited in the process of equipment operation to touch the rotating parts, is strictly prohibited to use the enameled wire over the specification (more than the equipment allowed to be very large diameter or very small diameter), is strictly prohibited to arbitrarily change the parameter settings of the equipment, etc.; inform the staff in the process of the operation of the need to wear a good personal protective equipment, such as protective glasses, gloves, etc., to prevent enameled wire scratches or splash the tip injury; require staff to strictly follow the rules and regulations to ensure the safety of the equipment. Require employees to operate in strict accordance with the operating procedures to avoid damage to equipment or product quality problems caused by improper operation.

3、Precautions

l Electrical: Explain in detail the electrical risks of the equipment, such as the danger of electric shock. Teach employees that before operating the equipment, they must ensure that the equipment is well grounded to prevent leakage accidents; it is strictly prohibited to operate the equipment with wet hands, and they are not allowed to touch the electrically charged parts of the electrical components; when carrying out electrical repairs or inspections, the power supply must be cut off first, and the warning sign of “someone is working, prohibit the closing of the gate” must be hung in the power switch; regularly check the Whether the wires, plugs, sockets and other parts of the electrical system are broken or aging, and if there are any problems, they should be replaced in time; train employees in first aid for electrocution, so that they can take first aid measures correctly in case of electrocution accidents.

l Machinery: Inform employees of the mechanical hazards during the operation of the equipment, such as the winding spindle, transmission parts, wire arrangement mechanism, etc. may cause injuries to the human body when rotating at high speeds, such as pinching, entanglement and other injuries. It is strictly prohibited to open the protective door or reach into the equipment when the equipment is running; when installing, dismantling the winding mold or making adjustments to the equipment, it is necessary to stop the machine and use the appropriate tools, and it is strictly prohibited to carry out these operations when the equipment is running; regularly check the protective devices of the equipment (such as the protective door, guardrail, interlocking device, etc.) is intact and effective, and if damaged, it should be repaired or replaced in a timely manner; teach the employees to pay attention to avoid moving parts and prevent collision when they walk around the equipment; and to avoid the impact of the equipment and the equipment. Teach employees to avoid moving parts when walking around the equipment to prevent collision and injury.

l Other matters: Remind employees to maintain good ventilation in the workplace, because the process of winding may produce volatiles of enameled wire, which may be harmful to human health if inhaled for a long time; clean up and properly store flammable and explosive materials around the equipment to prevent fire and explosion accidents; teach employees the correct use of fire extinguishers and other fire fighting equipment, and learn the location of emergency evacuation routes and exits in the workplace to ensure that in case of fire and other emergencies, they should pay attention to avoiding moving parts. position, to ensure that in the event of fire and other emergencies can quickly evacuate the scene.

4、Quality Control Points

l Winding quality standards: clearly inform the staff of the quality standards of stator winding, such as the number of turns of the winding should be accurate, the error shall not exceed the specified range; the winding should be tight, even, no cross, overlap, loose and other phenomena; the insulation layer of the enameled wire should not be damaged, otherwise it will affect the insulation performance of the motor; the row of wires should be neat, even, the spacing is in line with the design requirements to ensure the even distribution of the magnetic field and the performance of the motor. Stability. Through the physical samples or pictures, let the employees visualize the appearance and quality requirements of qualified winding products.

l Process quality control: Teach employees how to carry out quality control in the winding process, such as after each layer or several turns, check the flatness of the winding and whether the tension is uniform; regularly use the turns counter to check whether the number of turns is accurate; pay attention to observe the quality of the enameled wire in the process of winding, such as peeling off the varnish, uneven diameter and other issues should be promptly stopped and replace the wire; emphasize that the employees should be strictly in accordance with the operating procedures and process requirements for the winding. Stress that employees should strictly follow the operating procedures and process requirements for winding, to avoid quality problems due to improper operation; record the quality data in the winding process, such as the number of turns, tension value, spacing, etc., in order to trace and analyze the causes of quality problems.

l Quality inspection methods: train employees to master some basic quality inspection methods, such as using calipers, micrometers and other tools to measure the wire diameter of the enameled wire, to check whether it meets the design requirements; the use of insulation resistance meter to detect the insulation resistance of the windings, to ensure that the insulation performance is good; through the visual inspection of the winding of the appearance of the quality of the winding, including the winding of the smoothness of the winding, the row of wires, the completeness of the wire, etc.; for some complex quality problems, such as the inductance of the winding of the winding of the inductance of the winding of the winding, the row of wires, etc. For some complicated quality problems, such as the inductance of the winding, capacitance and other parameters to meet the requirements, you can use professional testing equipment for testing, so that employees understand the principles and operating procedures of these testing methods, so that in the process of winding can be found in a timely manner to solve quality problems.

5、Daily maintenance knowledge

l Cleaning and maintenance: Teach the staff to clean the equipment every day, including wiping the dust and oil on the surface of the body, cleaning the threads, wastes and dust on the workbench to keep the equipment neat and clean; use compressed air or vacuum cleaner to clean the inside of the equipment on a regular basis, such as the winding spindle, the wire arrangement mechanism, the electrical control cabinet, etc., to clear off the dust and sundries, to prevent the accumulation of too much dust leading to equipment failures; clean the equipment's Cleaning of wire crossing devices, such as wire nozzles, wool felt, etc., to ensure that the enameled wire is not polluted or damaged during the winding process.

l Lubrication and maintenance: introduce the parts of the equipment that need lubrication, such as winding spindle bearings, guide slides, transmission gears, screws and nuts, etc., and explain the type and specification of lubricant or grease used for each lubrication point; formulate the lubrication plan, specify the lubrication cycle, and teach the staff how to use the lubrication tools (e.g. grease injector, grease gun, etc.) for lubrication operation, so as to ensure that the parts are adequately lubricated to reduce wear and prolong the service life of the equipment. Make lubrication plan, specify lubrication period, teach employees how to use lubrication tools (e.g. oil injector, oil gun, etc.) correctly for lubrication operation, ensure the parts are adequately lubricated, reduce the wear and prolong the service life of the equipment.

l Mechanical parts inspection: train the staff how to check whether the mechanical parts of the equipment are normal, such as observing whether the winding spindle has bending and jumping phenomenon, whether the bearing has abnormal sound and heat; check whether the belt and chain of the transmission parts are properly tightened, whether there is any wear and tear, breakage phenomenon, and whether the gear mesh is good; check whether the row of rails are parallel, whether the straightness is in line with the requirements, and whether the movement of the slider is flexible; Regularly check the tightening of mechanical parts, and tighten the loose bolts, nuts and other fasteners to prevent equipment failure or accidents caused by loose parts.

l Maintenance of electrical system: Teach the staff to regularly check whether the wiring of the electrical system is firm, whether there is any looseness, oxidation, burning, etc., and if there is any problem, repair or replace it in time; check whether the working condition of the electrical components (e.g. contactors, relays, switches, buttons, etc.) is normal, and whether there is any abnormal heat, noise, or malfunctioning of the action, etc., and replace the faulty components in time; use the multimeter and other tools to test the winding resistance and insulation resistance of the motor on a regular basis. Motor winding resistance, insulation resistance and other parameters to ensure the normal operation of the motor; electrical control system backup to prevent program loss, and regularly check the operation of the control system, update the software version in a timely manner, in order to improve the stability and performance of the equipment.

6, fault diagnosis and troubleshooting basis

l Common fault phenomenon identification: Introduce the common fault phenomena of the equipment to the employees, such as motor does not start, unstable winding speed, uneven rows of wires, runaway tension, broken wires, abnormal vibration and noise of the equipment, etc. Through pictures, videos or actual case demonstrations, the employees can quickly and accurately identify these fault phenomena to provide prerequisites for the subsequent troubleshooting diagnostics and troubleshooting.

l Troubleshooting Methods: Teach employees the basic troubleshooting methods, such as according to the fault phenomenon, first start from the simple aspects of the inspection, such as whether the power supply is normal, whether the wiring is loose, whether the fuse is blown, etc.; for the electrical faults, you can use a multimeter and other tools to measure the parameters such as voltage, resistance, current, etc., to determine whether the electrical components are damaged; for the mechanical fault, you can observe the appearance of the components, For mechanical failures, you can determine the cause of the failure by observing the appearance of the parts, movement, listening to the sound, touching the vibration, etc.; gradually narrow down the scope of the failure to determine the specific parts and causes of the failure.

l Simple fault elimination: train employees to eliminate some simple faults, such as replacing blown fuses, tightening loose terminals, cleaning up blocked air or oil pipes, etc.; for some faults that require replacement of parts, such as motor brush wear, sensor failure, etc., teach employees how to correctly dismantle and replace these parts, and emphasize that after replacing the parts should be debugging and testing to ensure that the equipment Restore normal operation; let employees understand that when encountering complex faults that can not be eliminated by themselves, they should report to their supervisors or professional maintenance personnel in a timely manner, and should not carry out maintenance operations without authorization, so as not to cause greater equipment damage or accidents.

7、Teamwork and communication

l Collaboration in the workflow: explain the roles and responsibilities of employees in the entire production process, as well as the collaborative relationship with the upstream and downstream positions. For example, with the material supply staff to ensure the timely supply of enameled wire, stator core and other raw materials, and quality inspection staff to ensure that the quality of winding products in line with the standard, and equipment maintenance staff to collaborate on the maintenance of equipment and troubleshooting, etc.; emphasize the importance of teamwork to improve production efficiency and product quality, and encourage employees to actively cooperate with the work of other positions, and work together to complete the production task.

l Information Communication and Feedback: Teach employees how to carry out effective information communication at work, including reporting work progress, equipment operation, quality problems, etc. to supervisors; exchanging operation experience, technical tips, trouble shooting methods, etc. with colleagues; transferring product quality information and equipment status information to downstream positions; establishing a good information feedback mechanism to ensure that problems are solved in time to avoid production delays or problems caused by poor information. To establish a good information feedback mechanism to ensure that problems can be solved in a timely manner, to avoid production delays or quality problems due to poor information; to encourage employees to put forward suggestions and ideas to improve workflow, productivity and product quality, and to promote the overall level of the team.

※ If you need any help, please contact the technical specialist of Xinhui Electromechanical Equipment Co.