What are the common electrical faults and solutions of the series excitation motor motor stator paint dripping machine?

What are the common electrical faults and solutions of the series-excited motor-motor stator paint dripping machine?

1、Power supply failure

The power supply is out of phase:

Failure phenomenon: the motor does not run smoothly, or even can not start, accompanied by abnormal humming sound, ammeter pointer swing.

Solution: Use a multimeter to check the power supply line, see if there is a fuse blown, switch contacts poor contact or broken wires, etc., and timely replacement of fuses, repair or replacement of switches, connect the broken wires.

Voltage is too low or too high:

Failure phenomenon: paint dripping machine work efficiency is reduced, the motor heating is serious, there may be insulation aging, burning and other problems, affecting the quality of paint dripping.

Solution: use a voltmeter to measure the power supply voltage, if the voltage is too low, check whether the power supply line is too long, too thin or there are problems such as poor contact, you can thicken the power supply line or solve the poor contact points; if the voltage is too high, consider installing a voltage regulator to stabilize the voltage.

2、Motor part of the fault

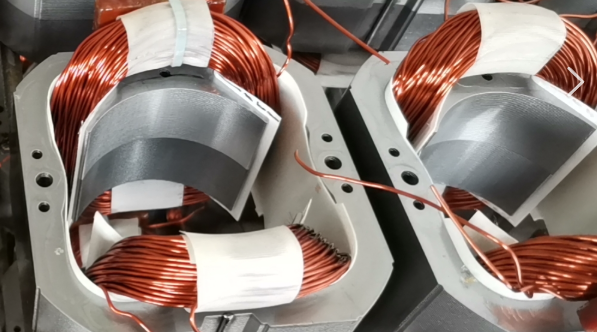

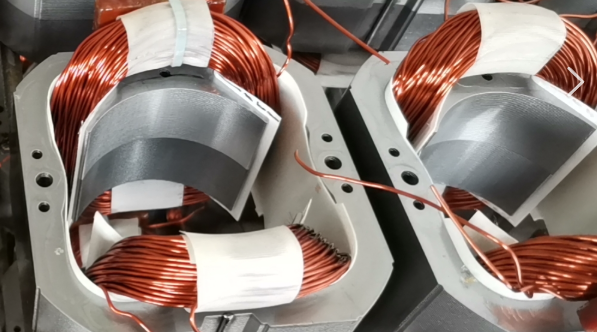

Stator winding disconnection:

Failure phenomenon: the motor can not start, or in the process of running suddenly stop, measure the stator winding resistance, the resistance value is infinity.

Solution: Heat the broken part of the winding to the temperature permitted by the insulation level to soften the paint, then pick up the broken wire, use the same specification of enameled wire to make up for the broken part, wrap the insulation, and then go through the painting and drying process.

Stator winding short circuit:

Failure phenomenon: motor running current is too large, serious heat, there may be smoke, burnt smell and other phenomena, the efficiency of the paint dripping machine is reduced, or even can't work normally 2.

Solution: Heat the grounded or short-circuited part of the winding to the temperature permitted by the insulation grade, soften the paint, pad the grounded or short-circuited part with insulation to separate it, then paint and dry it; if the short-circuit is serious, the whole stator winding needs to be replaced.

Stator winding grounded:

Fault phenomenon: the motor shell is electrified, there is a potential danger of accidents, and at the same time, it may lead to unstable operation of the motor, or even unable to start normally.

Solution: check the insulation between the stator winding and the motor shell, to find out the grounding fault point, such as insulation breakage, can be re-wrapped insulation; if the winding is damp, need to be dried; such as grounding fault is serious, may need to replace the stator winding.

3、Control circuit failure

Contactor failure:

Failure phenomenon: the contactor can not be properly absorbed or released, resulting in the motor can not start or stop, or in the process of operation, there is a sudden power failure or energized.

Solution: Check whether the coil of the contactor is damaged, if damaged, the coil needs to be replaced; check whether the contacts of the contactor are in poor contact or ablation, sandpaper can be used to polish the contacts or replace the contactor.

Relay failure:

Fault phenomenon: the relay can not act normally, affecting the automatic control function of the paint dripping machine, such as not being able to drip paint, drying and other operations according to the set program.

Solution: check the coil and contacts of the relay to see if there is a short circuit, broken circuit or poor contact and other problems, if any problems in time to replace the relay; at the same time, check whether the control signal of the relay is normal, such as sensor signals, button signals and so on.

4、Sensor failure

Temperature sensor failure:

Failure phenomenon: unable to accurately measure the temperature inside the paint dripping machine, resulting in drying temperature is too high or too low, affecting the quality of paint dripping and motor performance.

Solution: Use the standard thermometer to calibrate the temperature sensor, if the sensor is damaged, it needs to be replaced in time.

Liquid level sensor failure:

Failure phenomenon: unable to accurately measure the liquid level of the paint, which may lead to insufficient paint or overflow, affecting the paint dripping effect and working environment.

Solution: Check whether the installation position of the liquid level sensor is correct, whether there is debris blocking the sensor probe; if the sensor is damaged, it needs to be replaced in time.

5、Failure of heating device

The heating element is damaged:

Failure phenomenon: the heating device can not be heated properly, resulting in paint can not be dried or drying time is too long, affecting the efficiency of the paint dripping machine.

Solution: Use a multimeter to check the resistance of the heating element, such as the resistance value is infinity or a large difference from the nominal value, indicating that the heating element is damaged and needs to be replaced in time.

Temperature control failure:

Failure phenomenon: the heating device can not be heated in accordance with the set temperature, the temperature may be too high or too low, affecting the quality of dripping paint.

Solution: Check whether the parameters of temperature controller are set correctly, such as proportionality coefficient, integral time, differential time, etc.; check whether the sensor input of temperature controller is normal, such as sensor is damaged, need to be replaced in time; such as the temperature controller itself is faulty, need to replace the temperature controller.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool to seek help.