Series excitation motor motor stator automatic slotting machine what are the common mechanical failures and solutions?

First, the slot paper transfer mechanism failure

(A) failure phenomenon

l slot paper transmission is not smooth

Slot paper jamming, blocking in the transmission process, resulting in slot paper can not reach the insertion position, affecting work efficiency.

The slotted paper may be wrinkled, torn, etc., making it impossible to place it properly when inserting it into the stator slot.

l Unstable transfer speed

The speed of transferring slot paper is fast and slow, which makes the rhythm of inserting slot paper into the stator slot disturbed, and may lead to inaccurate or incomplete insertion position of slot paper.

(ii) Cause analysis

l Wear and tear of mechanical parts

After a long time of contact and friction with the slot paper, the surface of the transmission rollers, guide wheels and other parts are worn out, which makes the friction force uneven and leads to poor transmission of slot paper.

Transmission chain, belt and other parts wear, there will be slack or jump teeth phenomenon, affecting the stability of the transmission speed.

Foreign matter blocking

Dust, confetti and other foreign matter in the working environment enter into the transmission mechanism and get stuck in the transmission roller, slot paper channel and other positions, hindering the normal transmission of slot paper.

l Improper tension adjustment

The tension adjustment device of the slot paper transmission is not set reasonably, when the tension is too large, it will lead to tearing of the slot paper, and when the tension is too small, it will make the slot paper transmission not close, and there will be jamming.

(iii) Solution

l Replace worn parts

Regularly check the wear and tear of conveyor rollers, guide wheels, drive chains and belts. When serious wear is found, replace the parts with the same specifications in time to ensure that the surface of the transfer mechanism is smooth and the friction is even.

For the worn transmission chain or belt, readjust the tension after replacement to ensure the stability of transmission.

l Clean the foreign matter

Regularly clean the transmission mechanism, use compressed air to blow away foreign objects such as dust and paper. If the foreign matter is stuck in the deeper position, you can disassemble part of the transmission parts to clean.

l Adjusting the tension

According to the material and thickness of the grooved paper, adjust the tension adjusting device reasonably. Through trial and error, you can set an initial tension value, and then fine-tune it according to the transmission of slot paper until the slot paper can be transmitted smoothly and tightly.

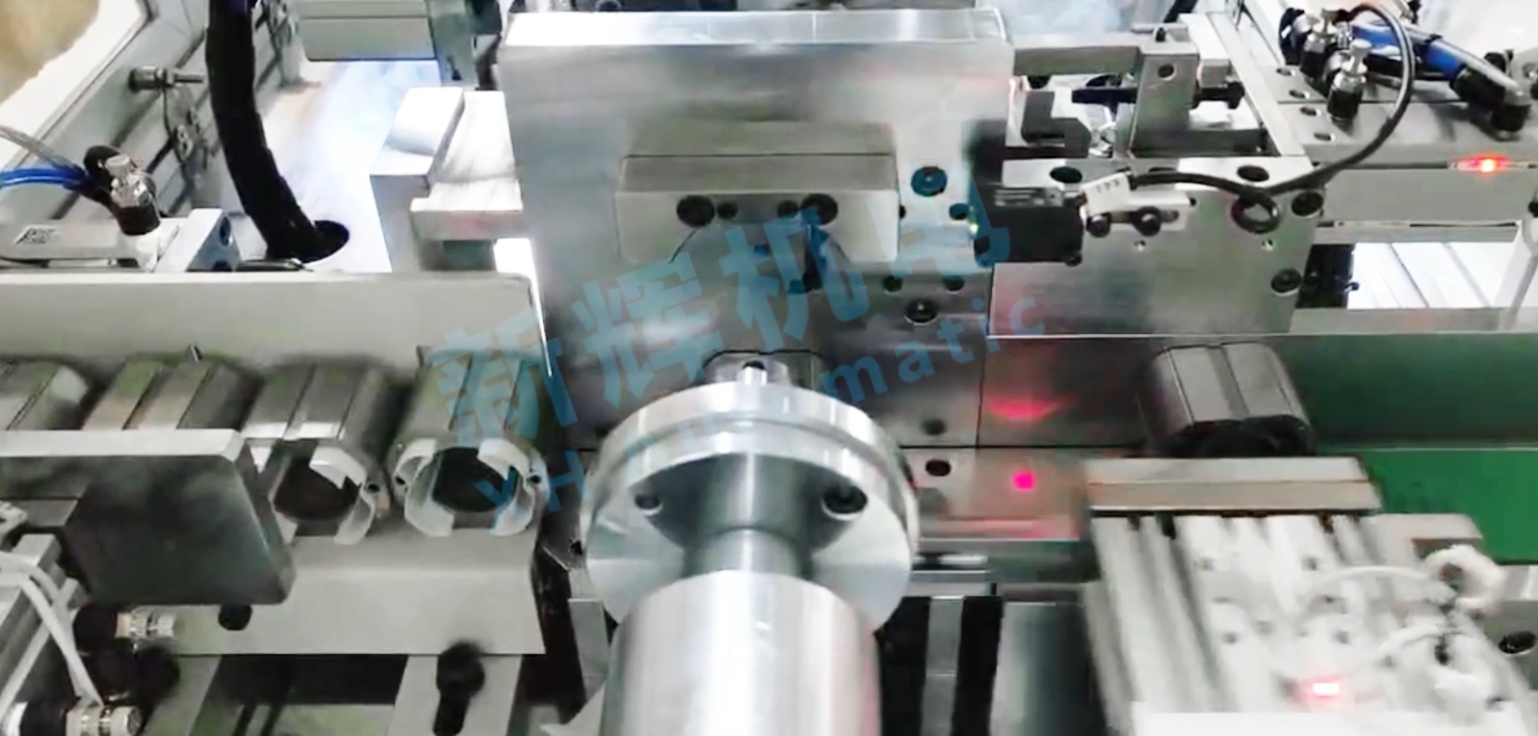

Second, the slot paper insertion mechanism failure

(A) Failure phenomenon

l slot paper insertion position deviation

The slot paper can not be inserted accurately into the center of the stator slot, and may be biased to one side, resulting in the slot paper can not completely cover the stator slot wall, affecting the performance of the motor.

l Insufficient or too deep insertion depth

Insufficient insertion depth of the slot paper makes the slot paper not securely fixed in the stator slot and easily loosened; too deep insertion may damage the stator slot or the slot paper itself, which will also affect the subsequent assembly of the motor.

l Insertion tool damage

The tools used for inserting slot paper (such as pins, push plates, etc.) are bent, broken, etc., and the slot paper cannot be inserted into the stator slot normally.

(ii) Cause analysis

l Decrease in the precision of the positioning device

The positioning devices of the slot paper insertion mechanism (such as positioning pins, positioning blocks, etc.) are shifted after long-term use or vibration, resulting in inaccurate insertion position.

The wear and tear of the positioning device will also affect the positioning accuracy, making the slot paper insertion position deviation.

l Insertion power system abnormal

Driving the insertion tool motor, cylinder and other power sources failures, such as motor speed instability, cylinder pressure, etc., will lead to uneven insertion depth.

Power transmission components (such as silk rod, connecting rod, etc.) loose, worn or deformed, will also affect the insertion depth.

l Insertion tool strength is insufficient or damaged by external forces

The material of insertion tools does not meet the requirements or is of poor quality, and is easily damaged during long-term use.

During operation, if there are foreign objects in the stator groove or the groove paper is too hard, etc., the insertion tool may be damaged by excessive resistance.

(iii) Solution

l Calibrate the positioning device

Regularly check the positional accuracy of the positioning device, and use gauges (such as calipers, micrometers, etc.) to measure and adjust the positioning pins, positioning blocks, etc., to ensure that their positions are accurate.

For worn-out positioning devices, replace them in time and recalibrate the positioning accuracy.

l Check and repair the power system

Check the working status of the power source. For the motor, check whether its winding is normal and whether its speed is stable; for the cylinder, check whether its air pressure is normal and whether its sealing is good.

Tighten the connecting screws of the power transmission parts, and check whether the screws, connecting rods and other parts are worn or deformed. If there is wear, replace them in time; if there is deformation, repair or replace them.

l Replace and optimize the insertion tool

When the insertion tool is damaged, immediately replace it with a high-quality tool of the same specification.

According to the characteristics of the grooved paper and the requirements of the stator groove, select the insertion tool with appropriate strength and shape, and pay attention to avoid excessive external force in the process of use.

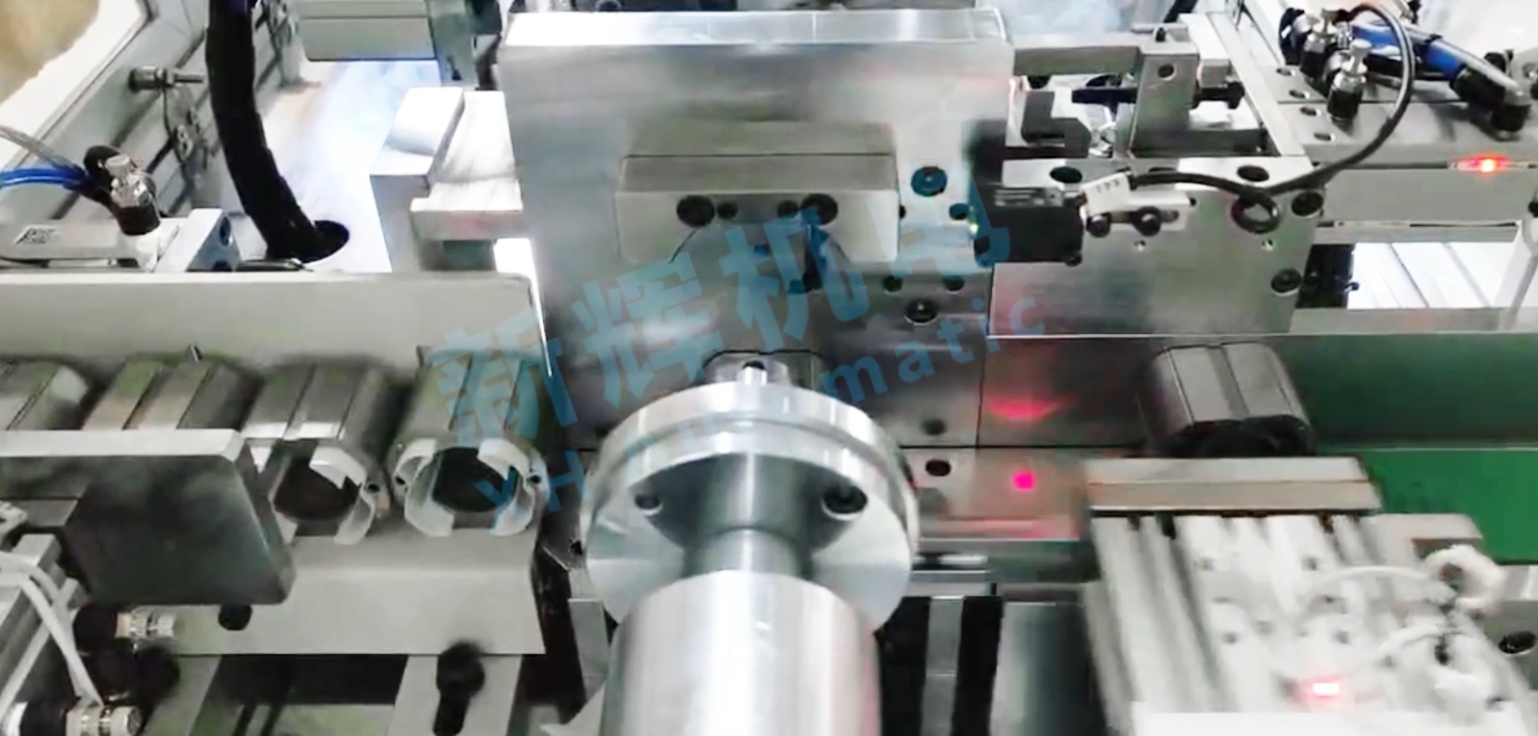

Third, the stator fixing mechanism failure

(A) Failure phenomenon

l Stator fixed insecure

The stator is displaced during the insertion of slot paper, resulting in inaccurate slot paper insertion position, and may even damage the stator and slot paper.

l Stator surface damage

When the stator fixing mechanism clamps the stator, it may cause scratches, indentations and other damages to the surface of the stator, affecting the quality of the stator.

(ii) Cause analysis

l Loose or worn clamping device

The screws of the clamping device such as fixture and jaws used for fixing the stator are loose, making the clamping force insufficient to fix the stator firmly.

Wear of the clamping surface of the clamping device reduces the contact area with the stator and lowers the friction, which also causes the stator to be fixed insecurely.

l Clamping force is too large or uneven

The pressure of the clamping device is not properly adjusted, and if the pressure is too large, it will cause damage to the surface of the stator; if the pressure is not uniform, it will make the stator locally overloaded, resulting in deformation or displacement of the stator.

(iii) Solution

l Fasten and replace the clamping device

Regularly check the connecting screws of the clamping device and tighten them in time if they are found to be loose.

Check the wear of the clamping surface of the clamping device, and replace the clamping device with a new one or repair the clamping surface, such as grinding and replacing the wear-resistant shims, etc., for the parts with serious wear.

l Adjust the clamping force

Use pressure sensors and other tools to readjust the clamping force of the clamping device so that it can firmly fix the stator without causing damage to the surface of the stator. At the same time, to ensure that the clamping force is evenly distributed on the surface of the stator, it can be realized by adjusting the position of the fixture or adopting the multi-point clamping method.

※ If you still can't solve the problem by the above ways and means, please contact the technical specialist of Xinhui Mechanical & Electrical Equipment Co.