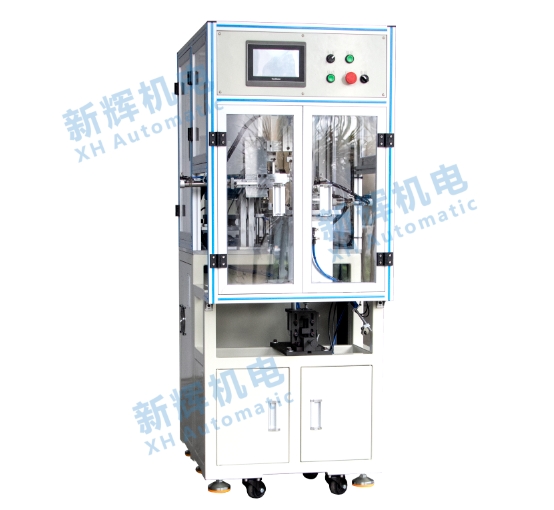

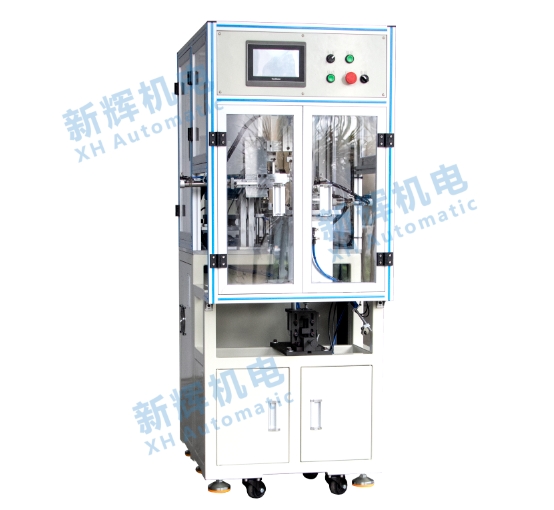

What are the contents of the pre-service training for employees of motor motor rotor automatic spring clamping machine?

1, the basis of machine operation

l control panel function: a detailed explanation of the control panel of the various buttons, switches, lights on the function and purpose. For example, how to operate the start button to open the machine's automatic mode of operation, emergency stop button in what circumstances need to be pressed and pressed after the change in the state of the machine, the indicator light flashes in different colors represented by the machine's operating status (such as the green is always on indicates normal operation, the red blinking indicates a fault alarm, etc.). Through practical demonstration and hands-on operation, ensure that employees are familiar with and can accurately use the control panel for basic machine control.

l Correct start-up and shut-down procedures: when starting up the machine, check whether the power connection is normal, whether the pressure of the gas source is up to standard, whether the mechanical parts are in the initial position, etc., and then turn on the power supply, gas source and machine control system according to the specified order; when shutting down the machine, stop the machine operation first, wait for the complete stop of the moving parts, and then shut down the machine control system, the gas source and the power supply and carry out the necessary cleaning and checking work. and check the work. Each step is repeatedly emphasized and demonstrated so that the employees can develop standardized switching habits to ensure the normal service life and stable operation of the machine.

2、Clip spring installation process

l Circlip type and specification identification: show and explain the different types (such as shafts with circlips, holes with circlips), different specifications (such as different inner diameter, outer diameter, thickness size) of the characteristics of the circlip and the application of the scene. Through physical comparison and the use of measuring tools, employees can quickly and accurately identify the spring, to ensure that the installation process will not lead to product quality problems or machine failure due to the wrong choice of the spring.

l Installation steps and techniques: Detailed description of the specific steps of the installation of the circlip, from the gripping and positioning of the circlip to the accurate installation of the entire process into the slot of the motor rotor. For example, how to adjust the angle and strength of the spring installation tool to ensure that the spring enters the slot smoothly and is firmly installed; how to avoid deformation of the spring or scratching the surface of the rotor during the installation process and other skills. Through on-site demonstration and actual operation practice of employees, constantly correct the wrong operation, so that employees master the spring installation process, improve the installation efficiency and quality.

3、Standardized operation

l The use of personal protective equipment: require employees to operate the machine must be correctly worn before the personal protective equipment, such as protective caps to prevent accidental impact on the head, protective gloves to avoid the hand by the machine parts of the folder or scratches, goggles can effectively block the splash of metal shavings and other foreign objects into the eyes. Detailed explanations and demonstrations of the wearing method and inspection points of each kind of protective equipment are given, and regular inspections are carried out to ensure that employees strictly implement the requirements for the use of protective equipment.

l Precautions during machine operation: emphasize that during the operation of the machine, employees are not allowed to put their hands or other parts of the body into the movement area of the machine, such as the spring mounting mechanism, rotor handling device, etc., in order to prevent injuries caused by the moving parts of the pinch; it is strictly prohibited to carry out debugging, repairing or cleaning up the machine when it is in operation, such as the need for such an operation, you must stop the machine and make sure that it is in the state of protective locking; inform the employees how to identify the abnormal sound, vibration or smell of the machine. Tell employees how to recognize the abnormal sound, vibration or smell of the machine and other failure signals, and master the emergency response, such as immediately press the emergency stop button and notify the relevant personnel. Through case studies and warning videos, deepen employees' understanding of the operating procedures and attention to ensure stable production.

4、Quality Control Points

l Circlip installation quality standards: Clearly define the quality acceptance standards after the installation of the circlip, such as the circlip should be completely embedded in the rotor slot, and the exposed height of the circlip in the slot should be in line with the specified range; there should be no obvious deformation, looseness or offset phenomenon after the installation of the circlip; the cooperation between the circlip and the rotor should be close without too large or too small a gap and other issues. Through the physical display and the use of measuring tools, employees intuitively understand the quality standards, and master how to carry out quality inspection and judgment.

l Common quality problems and solutions: list the common quality problems that may occur during the installation of the spring, such as the spring installation is not in place, spring deformation, rotor slot damage, etc., and analyze the causes, such as improper size of the spring, improper adjustment of the installation tool, rotor machining accuracy is insufficient, etc.. For each quality problem, we will explain in detail the corresponding solutions, such as replacing the appropriate spring, readjusting the installation tool, repairing or scrapping the rotor slot, and so on. Through actual case studies and practical exercises, we cultivate employees' quality awareness and problem solving ability to ensure stable and reliable product quality.

5、Routine maintenance and repair

l The implementation of cleaning: Teach employees how to clean the machine on a daily basis, including the use of what kind of cleaning tools (such as clean soft cloths, brushes, vacuum cleaners, etc.) and cleaning reagents (such as special metal detergent, rust inhibitor, etc.), as well as cleaning the key parts (such as control panels, sensors, transmission components, fixtures, etc.) and frequency (such as surface cleaning at the end of the work every day, once a week, the internal cleaning, etc.). (e.g. surface cleaning at the end of each day, internal cleaning once a week, etc.). Through on-site demonstration and practical operation by employees, employees can master the correct cleaning methods, keep the machine clean and hygienic, and reduce machine failures caused by accumulation of dust, oil and other impurities.

l Troubleshooting and reporting of simple faults: Train the staff on how to carry out preliminary troubleshooting of some common simple faults, such as when the machine fails to start, check whether the power supply is on, whether the pressure of the gas source is normal, and whether there is a fault alarm message on the control panel, etc.; when the installation of the card springs is inaccurate, check whether the installation tool of the card springs is damaged, whether the specifications of the card springs are correct, and whether there is any foreign matter in the slot of the rotor. For simple faults that can be solved by themselves, such as replacing fuses, cleaning foreign objects, etc., teach employees how to deal with them correctly; for faults that cannot be solved by themselves, require employees to promptly and accurately report information such as fault phenomena, time of occurrence, and probable causes to the relevant maintenance personnel, so that the maintenance personnel can quickly diagnose and fix the faults, reduce machine downtime, and improve production efficiency.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.