Brushless motor motor manual stator slot paper machine employee pre-service training content?

First, the basic knowledge of equipment training

1、Equipment structure introduction

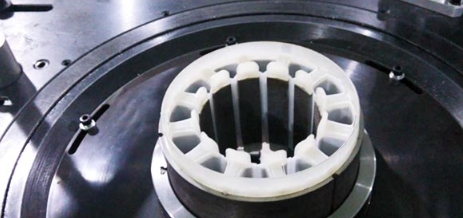

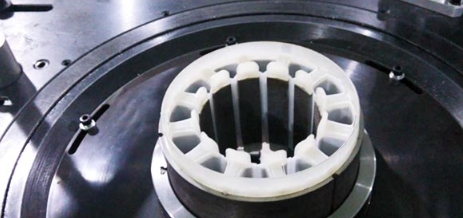

Detailed explanation of the overall structure of the slot paper machine, including the frame, paper feeding mechanism, slot paper forming mechanism, paper pressure mechanism and transmission and other major components. For example, show the staff how the frame provides stable support for the whole equipment, and how the paper feeding mechanism realizes the accurate delivery of paper.

Through physical display or high-definition pictures and video materials, let employees intuitively recognize the shape, position and connection of each structural component. For example, point out the specific position and role of different specifications of the paper feed roller, paper pressure spring.

2、Explain the working principle

Explain the working principle of brushless motor, explain the difference between it and traditional brush motor, and how to realize normal and stable operation through electronic commutation.

In-depth explanation of the workflow of the slotting machine, from the feeding of paper, in the slotting paper molding mechanism to complete the slotting paper production, to the paper pressure mechanism to ensure the quality of slotting paper throughout the process. For example, the photoelectric sensor detects the position of the paper as an example, explaining how the signal is transmitted to the control system, which in turn controls the motor and other executive parts to complete the processing of grooved paper.

3、Description of technical parameters

Introduce the key technical parameters of the slotting machine to the staff, such as the rated power, speed range and torque of the brushless motor, the adjustable range of the feeding speed, the great width and depth of the slotting paper and other parameters.

Emphasize the importance of understanding these parameters for proper operation of the machine. For example, in the case of different paper materials and thicknesses, how to reasonably adjust the feeding speed and motor torque, in order to ensure the processing quality of grooved paper.

Second, the operation process training

1、Preparation work before starting the machine

Instruct employees to check the appearance of the equipment to see if there are any damaged or loose parts, such as whether the screws are tightened, whether there are any cracks in the shell, and so on.

Teach employees to check the electrical system, including whether the power plug is plugged in properly, whether the wires are broken, whether the electrical components in the control cabinet are normal, and whether the voltage is stable within the range of equipment requirements.

Demonstrate how to perform necessary lubrication of equipment, such as which drive components to add oil or grease to, and the amount and frequency of addition. At the same time, check whether the protective devices of the equipment are intact, such as whether the emergency brake button is sensitive.

2. Start-up operation steps

Demonstrate the power-on process step by step in the correct order, first turn on the main power switch, then turn on the power supply of the control cabinet, wait for the equipment self-test to complete, and then start the brushless motor. In the process of power-on, explain to the staff the function and precautions of each step, such as observing the prompt information on the equipment display when powering on, and how to deal with the abnormal code if it appears.

3、Parameter setting method

According to different production needs, detailed introduction to how to set the parameters of the equipment, such as paper feeding speed, slot paper depth, pressure paper strength and other parameters of the adjustment method. Through the actual operation cases, let the staff understand the impact of different parameters on the quality of slot paper. For example, too fast feeding speed may lead to paper wrinkles, and inaccurate setting of slot paper depth will affect the winding effect of the motor stator.

4、Normal operation points

Demonstrate how to monitor the paper conveying situation during the operation of the equipment, such as observing whether the paper runs out of direction and whether it enters the slot paper forming mechanism smoothly. Teach employees how to deal with common problems in the operation of the equipment, such as how to stop and clean up correctly when the paper is jammed, and what initial inspection measures should be taken when the motor has an abnormal sound.

Emphasize the need to stay focused during operation, and not to leave the post without authorization or allow untrained personnel to operate the equipment.

5、Shutdown operation process

Demonstrate the correct sequence of shutdown, first stop the brushless motor operation, then turn off the power supply of the control cabinet, followed by cutting off the main power supply. After shutting down the machine, guide the staff to clean and organize the equipment, such as cleaning the paper shreds left on the conveyor belt and wiping the dust on the surface of the equipment.

Third, the protection of standardized training

1、Protection risk identification

Through pictures, videos or actual cases, show employees the potential risks during the operation of the slotting machine, such as mechanical injuries that may be caused by high-speed motors and transmission parts, electric shock hazards that may be triggered by the electrical system, as well as hand scratches that may be caused by the paper in the processing process.

Let employees intuitively understand the serious consequences of these risks may cause, improve the protection of employees' awareness.

2、Protection measures

Train employees to properly wear personal protective equipment, such as protective gloves, shoes, etc., explain the use and importance of each type of protective equipment.

Introduce the protective devices equipped with the equipment itself, such as guardrail, emergency brake button, leakage protection device, etc., and explain their functions and methods of use. Emphasize that these protective devices should not be removed or damaged during the operation of the equipment.

3、Operation standardization

Formulate and explain in detail to the staff of the protective operating norms, it is strictly prohibited in the operation of the equipment for cleaning, maintenance or adjustment work, you must first stop and cut off the power supply, until the equipment completely stops running before operation.

Teach employees to concentrate when operating the equipment, and not to leave their posts without authorization or let untrained personnel operate the equipment. In the event of an emergency, such as equipment fire, personnel injuries, etc., how to correctly use the emergency brake button and take appropriate emergency measures, such as dialing the emergency telephone, the use of fire extinguishers to extinguish the fire.

Fourth, maintenance knowledge training

1、Daily maintenance points

Train employees to clean the equipment every day, including cleaning the paper feeding mechanism, slotting paper forming mechanism, paper pressing mechanism and the surface of the equipment, such as dust, paper dust and oil and other debris, to keep the appearance of the equipment neat and clean.

Teach employees to check the connection of each mechanical component, such as the tightness of the chain and the tension of the belt, and make timely adjustments when problems are found. At the same time, pay attention to the sound and temperature when the equipment is running, such as whether the sound is abnormal when the motor is running, whether the temperature of the bearing part is too high, and report any abnormality in time.

2、Contents of regular maintenance

Introduce the periodicity and content of regular maintenance of the equipment, such as the maintenance of the motor at certain intervals, including checking the motor's carbon brushes (if any), commutator wear and tear, and lubricate the motor bearings.

Explain the methods and precautions for regular lubrication of transmission parts, such as chains, gears, bearings, etc., the type of lubricant or grease to be used, and the amount and location of additions.

Explain the importance of regular inspection of the electrical system, such as checking whether the line is aging, broken, whether the contacts of the electrical components are ablated, and find problems in time for replacement.

3、Wearable parts replacement method

Introduce to employees the types of wearing parts of the slot machine, such as knives, paper feed rollers, sensors, relays, etc..

Teach employees how to determine whether the wearing parts need to be replaced, for example, knife wear to a certain extent will affect the cutting quality of the slot paper, paper feed roller surface serious wear will lead to poor paper delivery.

Demonstrate the steps and techniques of replacing wearing parts through practical operation, and emphasize the precautions to be taken during the replacement process, such as cutting off the power supply when replacing electrical components to prevent electric shock.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.