What is the content of the pre-service training for employees of automatic slotting paper machines for tandem motor motors and stators?

Tandem motor motor stator automatic slotting machine employee pre-training content usually covers the following important aspects:

1、Equipment basics

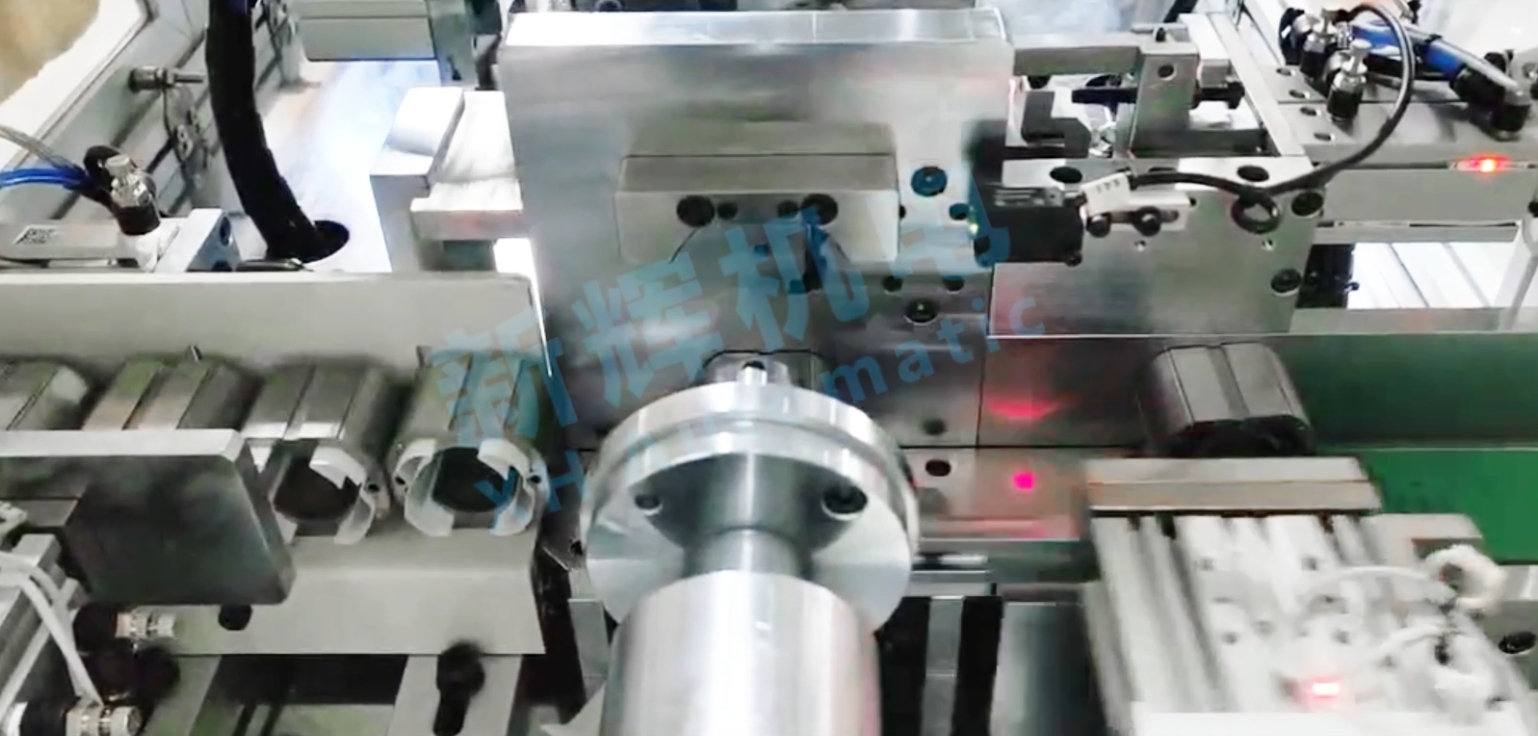

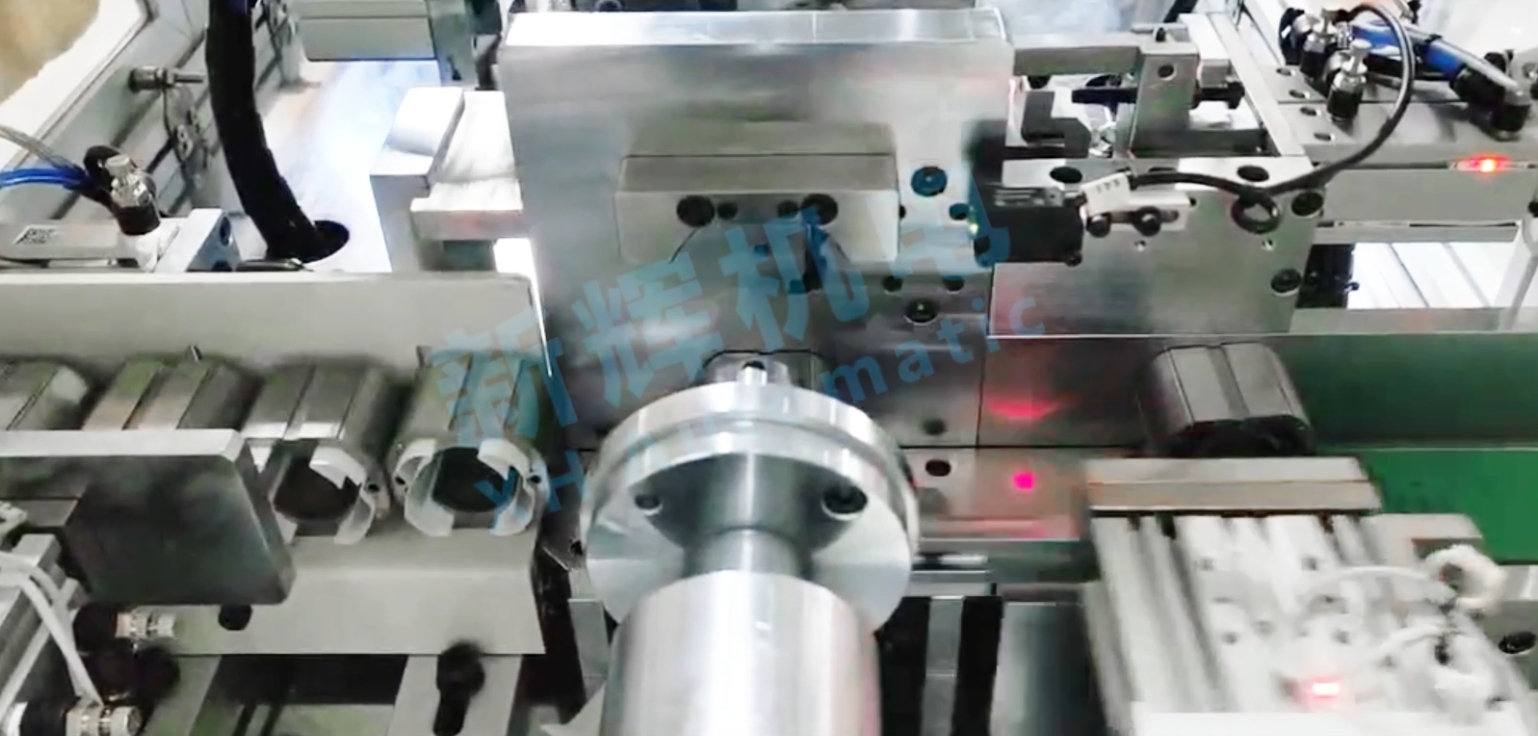

Equipment structure and principle: a detailed explanation of the overall structure of the tandem motor motor stator automatic slot paper machine, including various mechanical components (such as slot paper transfer mechanism, insertion mechanism, stator fixation mechanism, etc.) of the structure and function, as well as their mutual cooperation. At the same time, the working principle of the equipment is explained in depth, such as how slot paper is accurately transferred and inserted into the stator slot, the mechanical movement involved, power transmission and other principles, so that employees have a clear understanding of the operating mechanism of the equipment.

Overview of the electrical system: Introduces the electrical control system of the equipment, including the basic functions and workflow of the power supply, motor drive circuits, sensor signal processing circuits, as well as programmable logic controllers (PLCs) or other control units. Employees need to understand the role of different electrical components in the equipment, and how they work together to achieve the automated operation of the equipment, such as how the motor adjusts its speed according to the control signals to control the speed of the slot paper transfer, and how the sensor signals are fed back to the control unit to achieve precise positioning.

2、Operation standardization

Equipment start and stop process: Teach employees the correct equipment start-up steps, such as before starting what equipment needs to check the state (such as whether the power supply is normal, whether the components are in the initial position, whether there is no foreign body obstruction, etc.), according to what order to start each part. At the same time, clarify the standardized operation of equipment stopping, including the stopping process after the end of normal production and how to quickly stop the equipment in emergency situations to ensure that the equipment is normal.

Slot paper installation and replacement: Train employees on how to correctly install slot paper rolls onto the equipment, including how to adjust the tension, position and guidance of the slot paper to ensure that the slot paper can enter the conveyor and insertion system smoothly. In addition, when slot paper is used up or has quality problems and needs to be replaced, employees need to master the steps and techniques of replacement, such as how to quickly and accurately disconnect the old slot paper and connect the new slot paper, and how to avoid causing damage to the equipment or affecting the production schedule during the replacement process.

Stator Placement and Positioning: Explains the proper placement of the stator on the equipment and emphasizes the positioning requirements of the stator to ensure that the slot paper can be accurately inserted into the stator slot. Employees need to understand how to use the positioning devices on the equipment (e.g., positioning pins, positioning blocks, etc.) to adjust the position of the stator, as well as the matters that need to be paid attention to during the process of placing the stator, such as avoiding collision with the equipment components and preventing scratches on the surface of the stator.

Parameter setting and adjustment: Let the employees familiarize themselves with the various parameter setting functions on the operation panel of the equipment, such as the meanings and adjustment ranges of the parameters of the slot paper insertion depth, insertion speed, transfer speed, motor speed, and so on. Employees need to master how to reasonably set these parameters according to different production requirements and stator specifications to ensure the quality and efficiency of slot paper insertion. At the same time, train employees in the parameter adjustment process, such as avoiding arbitrary changes in key parameters leading to equipment failure or production accidents.

3、Protection knowledge

Introduction of protective devices: Introduce employees to the equipment equipped with a variety of protective devices, such as emergency brake button, guardrail, etc., and explain their functions and methods of use. Employees need to know under what circumstances can use these protective devices, and how to ensure that they are always in a normal working condition, such as regularly checking whether the emergency brake button is sensitive, whether the switch is reliable.

Operating procedures: Develop detailed operating procedures that emphasize the rules that employees must follow when operating the equipment, such as forbidding reaching out and touching moving parts while the equipment is in operation, not placing flammable or explosive materials around the equipment, and wearing personal protective equipment (e.g., protective gloves, goggles, etc.). Through case studies and practical demonstrations, employees will deeply understand the importance of complying with operating procedures in order to prevent accidents.

Emergency response to accidents: Train employees on emergency response in the event of equipment failure, fire, electrocution and other emergencies. For example, when equipment shows signs of failure such as abnormal noise or smoke, employees should take immediate measures (such as stopping equipment operation, cutting off the power supply, etc.); in the event of a fire, employees should use fire extinguishers or other fire fighting equipment to extinguish the fire, as well as how to evacuate quickly to an open location; in the event of an electrocution, how to give first aid, and so on. At the same time, regular emergency drills are organized for employees to improve their ability to cope with actual emergencies.

4、Quality control

Quality standard of slot paper insertion: Define the quality standard of slot paper insertion into the stator slot, including the depth of slot paper insertion, positional accuracy, and the degree of fit with the wall of the stator slot, and other aspects of the requirements. Employees need to understand how to observe and measure to determine whether the quality of slot paper insertion meets the standards, and how to adjust the equipment parameters or operating methods to correct quality problems when they are found.

Quality problem analysis and solution: train employees how to analyze the causes of common quality problems, such as deviation of slot paper insertion position, broken slot paper, and foreign objects in the stator slot. Through actual case studies and troubleshooting exercises, employees can master the methods and techniques to solve these quality problems, such as how to check whether the positioning device of the equipment is accurate, whether the transfer mechanism is smooth, whether the quality of the slot paper is qualified, etc., and be able to take appropriate measures to repair and improve the product quality and production efficiency according to the analysis results.

5、Maintenance knowledge

Daily maintenance tasks: Teach employees the content of daily maintenance work of the equipment, such as cleaning the surface of the equipment and the internal dust and debris, checking whether the fasteners of the equipment are loose, lubricating the moving parts of the equipment (e.g., bearings, guide rails, etc.), as well as checking the electrical wiring for breakage, aging and other conditions. Employees need to master the frequency and methods of daily maintenance, as well as matters requiring attention during maintenance, such as avoiding the use of sharp tools to scratch the surface of the equipment, and cutting off the power supply first when cleaning electrical parts.

Regular Maintenance Items: Introduce the regular maintenance items of the equipment, including replacing the wear parts (such as belts, chains, bearings, etc.), checking and calibrating the sensors, adjusting the precision parameters of the equipment, and conducting all the tests on the electrical system. Employees need to understand the periodicity of regular maintenance and the specific operation steps, as well as how to determine whether the wearing parts need to be replaced, whether the sensors are working properly, and so on. At the same time, train employees how to fill in the maintenance records when performing regular maintenance, so as to track and manage the maintenance of the equipment.

Common faults and reporting process: Familiarize employees with the common fault phenomena of the equipment (such as motor does not rotate, slot paper transfer is not smooth, control system error, etc.) and its possible causes, as well as how to conduct preliminary inspection and judgment when encountering faults. In addition, employees are trained how to report equipment failures to their supervisors in a timely manner according to the company's repair reporting process, including filling out repair orders, describing the failure phenomenon and possible causes, etc., so that maintenance personnel can respond quickly and carry out repairs to minimize equipment downtime.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. via the page chat tool for assistance.