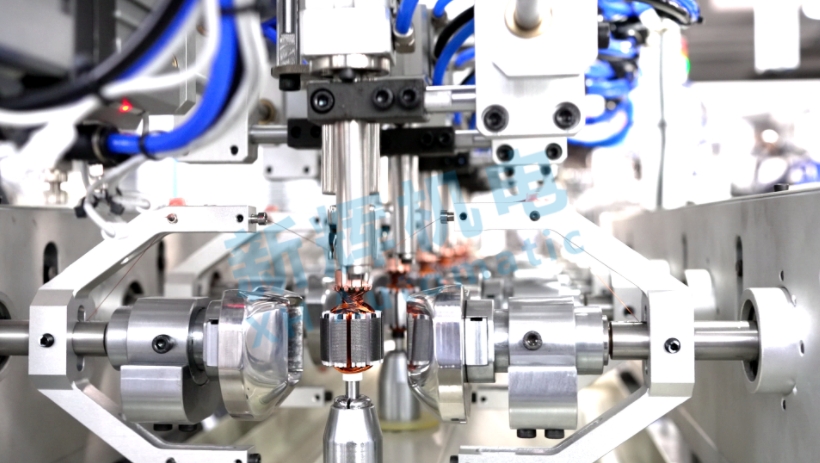

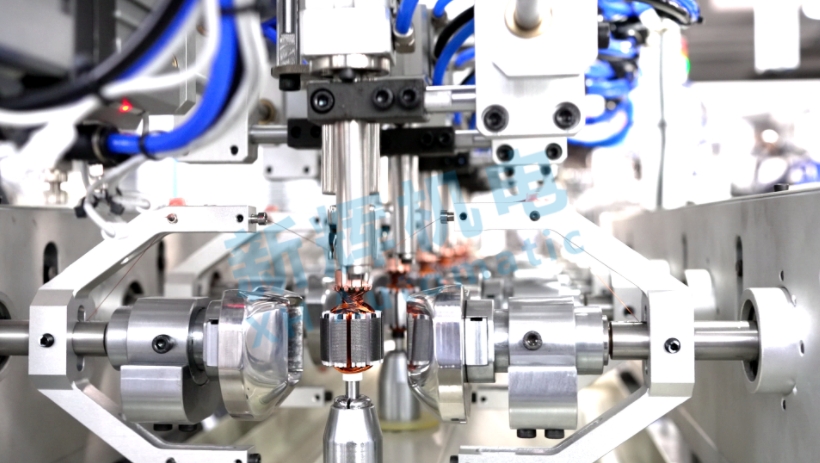

What are the common electrical faults and solutions for motor motor rotor manual six-station double flying fork winding machine?

The following are the common electrical faults and solutions for motor motor rotor manual six-station double flying fork winding machine:

1, power failure

Failure phenomenon: the equipment can not start, the power indicator does not light.

Possible causes: the plug is not plugged in tightly or the socket is not powered; fuse blown; power cord is damaged.

Solution: Check the connection between the plug and the socket to ensure that it is tightly plugged; replace the fuse; check the power cord, if broken, replace the power cord .

2、Motor failure

Failure phenomenon: the motor does not rotate or rotate abnormally, accompanied by buzzing sound or odor.

Possible causes: motor winding short-circuit, disconnection or grounding; motor overload; motor bearing damage; abnormal power supply voltage.

Solution: Use a multimeter to check the resistance value of the motor winding to determine whether it is short-circuited, disconnected or grounded, and replace the motor if there is any problem; check the load to avoid overloading the motor; replace the damaged motor bearings; and measure the power supply voltage to ensure that it is within the rated range.

3、Sensor failure

Failure phenomenon: the device can not detect the rotor position or state normally, resulting in winding action error.

Possible causes: sensor damage; sensor installation position is not appropriate; sensor and the controller between the connecting line is loose or broken.

Solution: Check the working status of the sensor, if damaged, then replace the same type of sensor; adjust the sensor's installation position to ensure that it can accurately detect the rotor; check the connecting line, re-plugging or welding loose, broken lines.

4、Controller failure

Failure phenomenon: the equipment runs out of control, can not be in accordance with the preset program for the winding operation; controller panel no display or display abnormalities.

Possible causes: damage to the internal components of the controller; program error or loss; controller power supply failure.

Solution: Contact the manufacturer or professional maintenance personnel to overhaul the controller, replace the damaged components; re-download or update the program; check the power supply of the controller to ensure its normal operation.

5、Circuit short-circuit or disconnection failure

Failure phenomenon: part of the equipment fails to function, smoke, burning and other phenomena; fuse frequently blown.

Possible causes: line aging, damage caused by short-circuit; loose solder joints, desoldering caused by disconnection; damage to electrical components triggered by short-circuit or disconnection.

Solution: carefully check the line, find and repair broken, short-circuit parts; re-welding loose, desoldering soldering joints; replacement of damaged electrical components.

6、Tension control system failure

Failure phenomenon: winding tension is too large or too small, resulting in line breakage or winding is not tight 1.

Possible causes: damage to the tension controller; tension sensor failure; failure of the relevant regulatory components.

Solution: Replace the tension controller; check the working status of the tension sensor, if any problem, then replace it; check and repair the regulating parts to ensure that it can normally adjust the tension.

7、Flying fork motor failure

Failure phenomenon: the flying fork can not be normal action or action is not smooth, affecting the efficiency and quality of winding.

Possible causes: flying fork motor damage; flying fork drive mechanism failure; motor drive failure.

Solution: Replace the flyer motor; check the flyer drive mechanism, clean, lubricate or replace the damaged parts; check the motor drive, if it is faulty, repair or replace it.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Mechanical and Electrical Equipment Co., Ltd. technical specialists through the page chat tool to seek help.