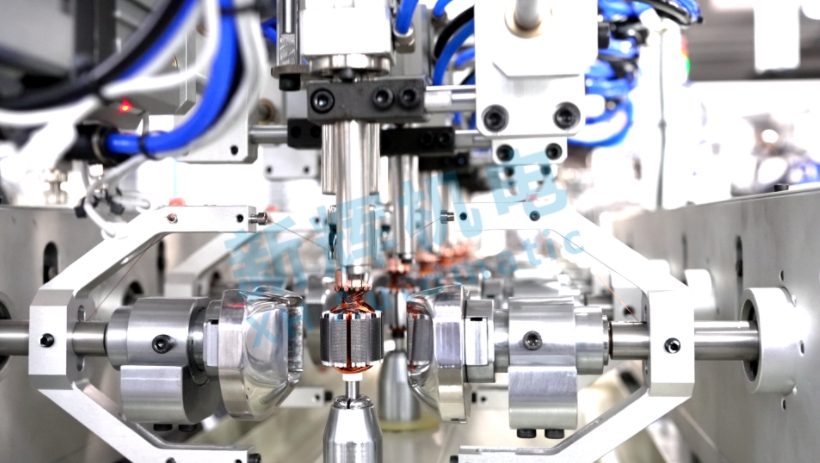

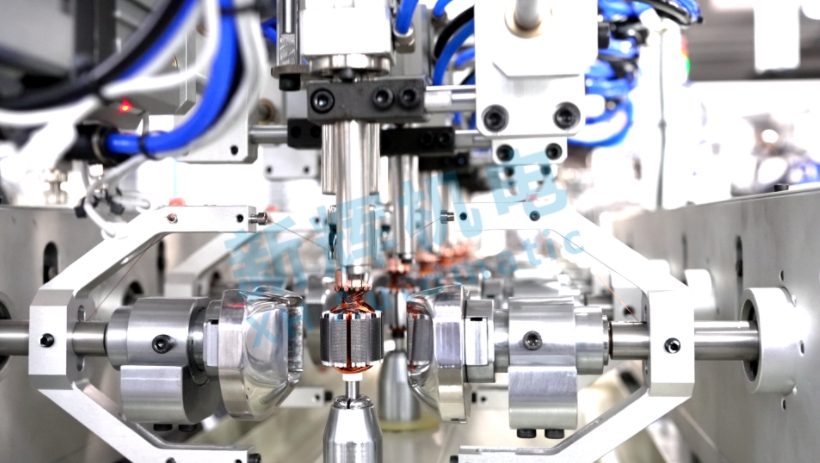

How to analyze and troubleshoot motor motor rotor automatic six station double flying fork winding machine?

Motor motor rotor automatic six-station double flying fork winding machine fault analysis and troubleshooting:

First, the basic process of fault analysis

1, observe the fault phenomenon

l When the winding machine failure, first of all, carefully observe the operating status of the equipment. This includes observing whether the equipment completely stops working, or some of the functions are abnormal, such as whether the flying fork can still move, whether the rotor can be indexed normally, whether the winding action is still going on.

l Pay attention to listen to the sound made when the equipment is running, for example, whether there is abnormal friction sound, impact sound or abnormal noise of the motor. Abnormal sounds may indicate wear and tear of mechanical parts, collision or motor failure.

l Observe the status of the indicator lights on the equipment, such as the power indicator light, fault indicator light, and the work indicator light of each station. The status of these indicator lights can provide clues about the failure of the electrical system of the equipment.

2. Collect relevant information

l Ask the operator about the operation of the equipment before the fault occurred, such as whether parameter adjustments were made, whether the raw materials were replaced, and whether the equipment was subjected to external shocks. This information helps to determine the possible causes of the failure.

l Check the operation records of the equipment, including the maintenance records of the equipment, the repair history, and recent changes in parameter settings. These records can help determine whether the failure is a new problem or a recurrence of an old problem that was not completely solved before.

3. Determine the scope of the fault

l According to the observed phenomena and collected information, initially determine whether the fault is in the mechanical system, electrical system, software system or other auxiliary systems (such as pneumatic or hydraulic system).

l For example, if the flying fork does not move but other electrical parts (such as indicator lights) are normal, then the fault may be concentrated in the mechanical transmission part of the flying fork or its drive motor part; if the device appears to be unable to save the parameter settings, then the fault may be related to the software system or storage module.

Second, the mechanical system failure analysis and troubleshooting

1、Flying fork mechanism failure

l Failure phenomenon: the flying fork can not start, the flying fork movement speed is not stable, the flying fork movement trajectory is not accurate or the flying fork jamming phenomenon.

Possible causes and troubleshooting methods:

l Problems of transmission parts: Check the transmission parts such as belt, chain or gear. If the belt is slack or broken, need to re-tension or replace the belt; for the chain, check whether there are links off or serious wear, if so, replace the chain; gear wear may lead to inaccurate transmission, need to replace the worn gear.

l Flying fork guide rail or slider failure: guide rail wear or slider jamming will affect the movement of the flying fork. Clean the guide rail and slider, remove dirt and debris, if the guide rail is seriously worn, need to replace the guide rail; if the slider is damaged, replace the slider, and add the right amount of grease after installation, to ensure that the flying fork movement is smooth.

l Flying fork motor failure: Check whether the flying fork motor is running normally. Use a multimeter to measure the winding resistance of the motor to determine whether the motor has a broken circuit or short circuit. If the motor is damaged, it is necessary to replace the motor of the same type and check whether the driver setting of the motor is correct.

2、Fixture system failure

l Failure phenomenon: the fixture can not clamp or loosen the rotor, resulting in the rotor shifting in the winding process, affecting the quality of winding.

l Possible causes and troubleshooting methods:

l Damage to the mechanical structure of the fixture: Check whether the collet, connecting rod and other parts of the fixture are deformed or broken. If the collet is worn out and can not clamp the rotor firmly, the collet should be replaced; the connecting rod is damaged, which will affect the opening and closing action of the fixture, so it is necessary to repair or replace the connecting rod.

l Fixture pneumatic or hydraulic system failure (if pneumatic or hydraulic fixture): check whether the pressure of the gas or hydraulic source is normal, whether there is leakage in the pipeline. For pneumatic fixture, check whether the air pipe is broken, whether the connector is loose, if there is any problem, repair or replace it in time; for hydraulic fixture, check whether the hydraulic oil is enough, whether the oil pump is working normally, to ensure that the hydraulic system can provide enough clamping force.

3, indexing mechanism failure

l Failure phenomenon: inaccurate rotor indexing, winding position deviation.

l Possible causes and elimination methods:

l Wear of the mechanical parts of the indexing mechanism: Check whether the cam, roller, ratchet and other parts in the indexing mechanism are worn. Worn cams will lead to a decrease in indexing accuracy and need to be replaced; worn rollers will affect the smoothness of the transmission and should also be replaced.

l Indexing sensor failure: the indexing sensor is used to detect the indexing position of the rotor. Check whether the sensor is covered by dust and oil, and clean the surface of the sensor. Use a multimeter to check whether the output signal of the sensor is normal, if the signal is abnormal, the sensor may be damaged, need to replace the same type of sensor.

Third, the electrical system failure analysis and troubleshooting

1, motor and drive failure

l Failure phenomenon: motor does not rotate, motor overheating, abnormal motor speed or drive alarm.

l Possible causes and troubleshooting methods:

l Power supply problem: Check the power supply of the motor, including whether the power cord is firmly connected and whether the voltage is normal. If it is a three-phase motor, also check whether the three-phase power supply is balanced. For the case of loose power cord, re-insert and tighten it; if the voltage is abnormal, you need to check the power supply line or use a voltage regulator to stabilize the voltage.

l Motor failure: As mentioned earlier, determine whether the motor is damaged by measuring the resistance of the motor winding. In addition, check whether the bearing of the motor is seized or worn. If the bearings are faulty, the bearings need to be replaced; if the motor is damaged, replace the motor, and when installing a new motor, pay attention to adjusting the motor's mounting position to ensure that it is properly connected to the drive components.

l Drive failure: check the drive alarm code, different drives have different alarm information, according to the alarm code can be initially determined the cause of the failure. For example, overcurrent alarm may be too large a motor load or drive internal short circuit; overheating alarm may be poor heat dissipation drive. Check whether the cooling fan of the drive is working properly and clean up the heat sink of the drive. If the internal components of the drive is damaged, you need a professional to repair or replace the drive.

2, sensor failure

l Failure phenomenon: inaccurate winding turns, tension control failure, position detection errors and other sensor-related problems.

l Possible causes and elimination methods:

l Sensor connection problems: check whether the sensor signal line is firmly connected, there is no loose, broken or short-circuit conditions. Re-plug the signal cable to ensure a good connection. If the signal line is damaged, you need to replace the signal line.

l Sensor damage: Use professional testing equipment or tools to check whether the sensor is working properly. For example, for counting sensors, you can manually trigger the sensor to check whether its counting function is normal or not; for tension sensors, you can use a standard tension test tool to compare the measured value of the sensor. If the sensor is damaged, replace it with a sensor of the same model and calibrate the new sensor according to the calibration program of the device.

l Sensor interference problems: Electromagnetic interference in the surrounding area may affect the sensor signal. Check whether there are large motors, transformers and other devices that generate electromagnetic interference around the equipment. If there is, you can take shielding measures, such as using shielded wires to connect the sensor, or keep the device away from the source of interference.

3, controller failure

l Failure phenomenon: the device can not start, running program error, parameter settings can not be saved or loaded.

l Possible causes and methods of elimination:

l Controller power problem: Check the power supply of the controller, including whether the power module is working properly, whether the fuse is blown. If the power module is faulty, you need to replace the power module; if the fuse is blown, check whether there is a short-circuit situation, and replace the fuse after eliminating the short-circuit.

l Controller program error: Try to reset the controller to restore its default settings. If the problem still exists after reset, the program may be faulty or missing. Contact the equipment manufacturer to obtain the correct version of the program and reprogram or update the software.

l Controller internal component damage: For complex controller failure, it may be the internal chip, capacitor and other components are damaged. This requires professional electronic maintenance personnel to use professional equipment for testing and repair, such as using an oscilloscope to check the signal waveform, using a multimeter to check the parameters of the components.

Fourth, the software system failure analysis and troubleshooting

1, parameter setting fault

l Failure phenomenon: winding parameters (such as turns, speed, tension, etc.) can not be set after the normal implementation, or parameter setting after the abnormal operation of the device.

l Possible reasons and troubleshooting methods:

l Parameter input error: double-check the parameter setting interface to make sure that the input parameters are in line with the requirements of the equipment and the actual winding situation. For example, the number of turns cannot be negative, and the speed setting cannot exceed the maximum allowable speed of the equipment, etc. If the parameters are input incorrectly, re-set them correctly. If the parameters are input incorrectly, re-set the parameters correctly.

l Parameter saving or loading problem: Check the parameter saving and loading function of the software. It is possible that the file for storing parameters is corrupted or there is a problem with the storage path of the software. Try to re-save the parameters, or find and fix the problem with the storage path. If the parameter file is corrupted, you can try to restore the parameters from the backup file.

2、Program operation failure

l Failure phenomenon: the winding machine is running according to the wrong program, such as the flying fork action sequence is wrong, the connection between the stations is not normal.

l Possible causes and elimination methods:

l Program logic error: check the programming logic of the software, it may be that the logic of the program is destroyed after updating the software, modifying the program or equipment failure. Contact the software developer or equipment manufacturer to get the correct program logic diagram, check and modify the program.

l Incompatibility between the program and the hardware: If the device has undergone a hardware upgrade or certain parts have been replaced, there may be incompatibility between the software and the hardware. Check the version of the software and the compatibility requirements of the hardware, and upgrade the software version or adjust the hardware configuration to match each other if necessary.