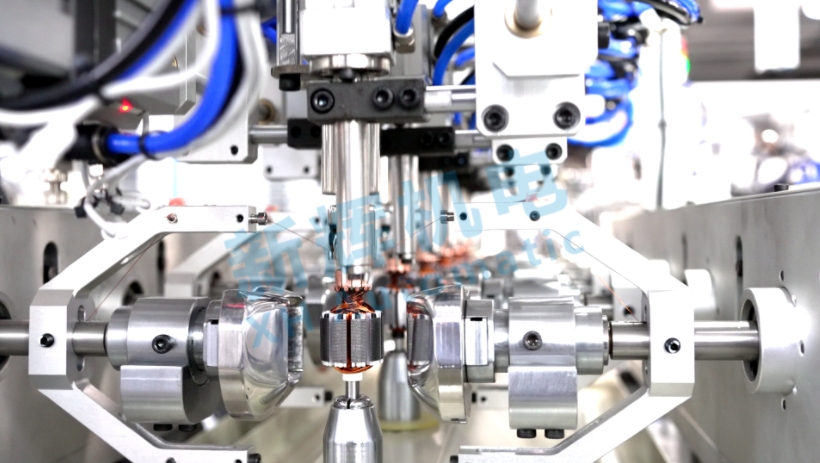

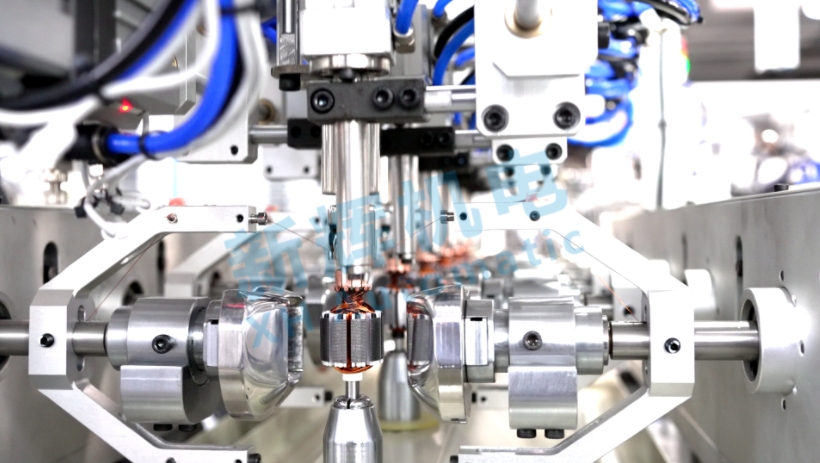

What are the common sensor failures and their solutions for motor motor rotor automatic six-station double flying fork winding machine?

Motor motor rotor automatic six-station double flying fork winding machine common sensor failures and solutions are as follows:

1、Position sensor failure

Failure phenomenon: inaccurate rotor indexing, resulting in deviation of the winding position; inaccurate starting position or stopping position of the flying fork, affecting the starting and ending positions of the winding, resulting in uneven winding or improper handling of the wire head and tail.

Possible reasons: the sensor is polluted by dust, oil and other contaminants after long-term use, which affects the accurate transmission of signals; the installation position is shifted, resulting in inaccurate position information detected; the sensor's own electronic components are aging and damaged, resulting in abnormal signal output.

Solution: regularly clean the sensor surface, remove dust and oil and other impurities; check and re-adjust the installation position of the sensor to ensure that its relative position to the detected parts is accurate; the use of professional instruments to detect the sensor's output signal, if the signal is found to be abnormal, timely replacement of the same type of sensor.

2、Tension sensor failure

Failure phenomenon: the tension of the wire is not stable, the tension of the wire is not consistent, which may cause the winding too loose or too tight; the tension sensor can not detect the change of the tension of the wire, resulting in the winding machine can not be automatically adjusted according to the tension of the wire speed.

Possible causes: the measuring element of the tension sensor is worn or damaged, affecting the accuracy of tension measurement; the calibration of the sensor is off, resulting in the measured value does not match the actual tension; the line connecting the tension sensor is disconnected, short-circuited or poorly contacted, so that the sensor can not work properly.

Solution: Replace the worn or damaged measuring elements of the tension sensor; re-calibrate the tension sensor to ensure that the measured value is accurate and reliable; check and repair the lines connecting the sensor to ensure that the lines are firmly connected, no breaks and short-circuit problems.

3、Speed sensor failure

Failure phenomenon: the rotational speed of the flying fork or wire feeding mechanism is unstable, unable to wind the wire according to the set speed; the rotational speed displayed by the speed sensor is inconsistent with the actual rotational speed, resulting in the control system of the winding machine is unable to accurately control the winding speed.

Possible causes: the probe of the speed sensor is damaged or the electronic components inside the sensor are faulty, which affects the collection and transmission of the speed signal; the gap between the sensor and the rotating parts is too large or too small, which leads to inaccurate signal detection; the mounting bracket of the speed sensor is loose, which affects the stability of the sensor and the quality of the signal.

Solution: Replace the damaged speed sensor probe or the whole sensor; adjust the gap between the sensor and the rotating parts to the appropriate range; check and tighten the mounting bracket of the speed sensor to ensure that the sensor is firmly installed.

4, counting sensor failure

Failure phenomenon: the number of winding turns is inaccurate, inconsistent with the set number of turns; counting sensor can not count properly, resulting in the winding machine can not automatically stop or the next operation.

Possible causes: the counting sensor sensor head is contaminated or damaged, can not accurately detect the number of turns of the winding; sensor signal processing circuit failure, resulting in the loss of counting signals or errors; counting sensors and the synchronization between the winding mechanism problems, affecting the accuracy of the count.

Solution: Clean or replace the sensor head of the counting sensor; check and repair the signal processing circuit of the sensor; check and adjust the synchronization device between the counting sensor and the winding mechanism to ensure that they are synchronized.

※ If the above ways and means still can not solve the fault of the equipment, please contact the technical specialist of Xinhui Mechanical & Electrical Equipment Co.