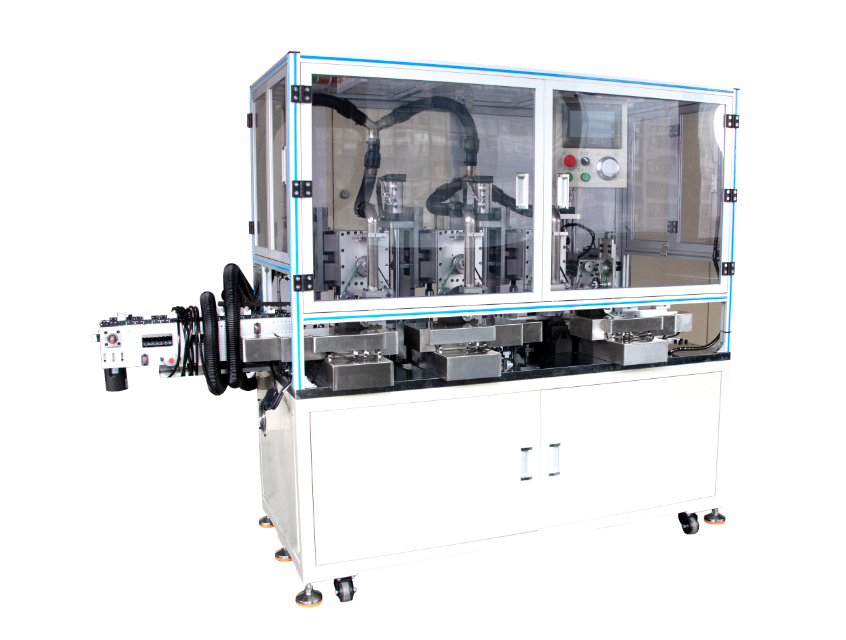

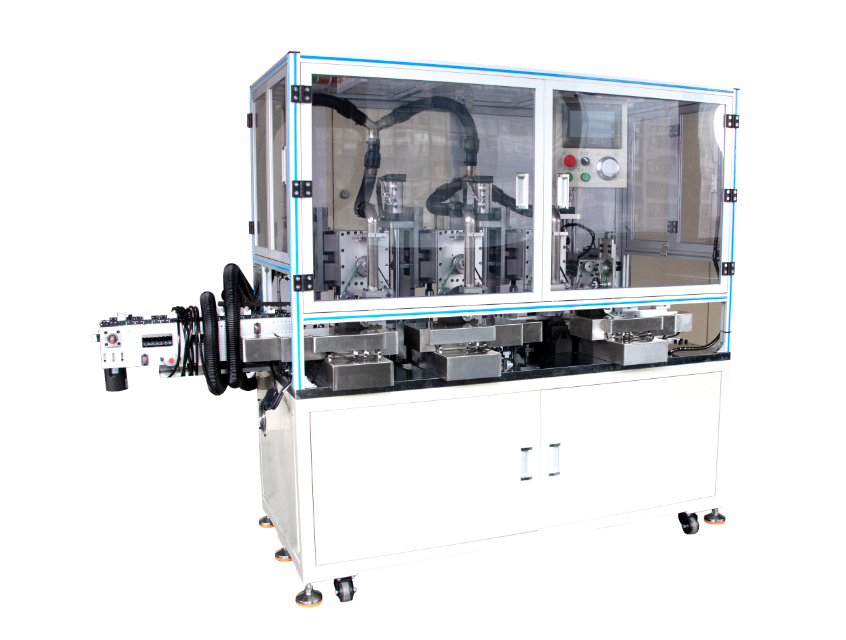

What are the common electrical failures and their solutions for motor motor rotor automatic three-station fine turning machine?

Motor motor rotor automatic three-station fine turning machine in the electrical common faults and their solutions are as follows:

1, the machine does not respond: If the switch machine does not respond, it may be due to incorrect wiring, the power supply is not open. The solution is to change the wiring, close the main power switch.

2, the electrode does not move: the power can start, but the electrode does not move, may be due to not connected to the air source, air pressure problems, air leakage, solenoid valve wiring error or disconnection, solenoid valve bad. The solution is to connect the air source, check the air pressure meter, change the air tube, connect the solenoid valve line or replace the electromagnetic valve.

3, current malfunction: fault display current malfunction, the possible causes are secondary short circuit, incorrect connection or component damage. The solution is to exclude the short circuit, notify the manufacturer.

4, the network pressure is too high or too low: the fault shows that the network pressure is too high or too low, the possible causes are fluctuations in the power grid. The solution is to check the power grid and wait for normal.

5、Output current is limited: the fault shows that the output current is limited and cannot reach the set value, the possible reason is that the load or circuit resistance is too large and the current cannot reach the set value. The solution is to check the output circuit, reasonable configuration; reduce the current setting.

6, sensor failure: automatic testing machine using the sensor may fail, resulting in inaccurate test data. The solution is to calibrate the sensor regularly and replace it in time when abnormalities are found.

7, controller failure: automatic test machine controller may fail, resulting in the machine can not run normally. The solution is to check the controller's circuit board, to confirm whether there is component damage, and make the necessary repairs or replacements.

8, power supply problems: automatic testing machine power lines may have poor contact or unstable voltage. The solution is to check the power supply line to ensure that the connection is firm, and use voltage stabilizing equipment to ensure stable voltage.

The above solutions provide for motor motor rotor automatic three-station fine-turning machine electromechanical failure of the basic processing methods, which helps to quickly diagnose and repair the problem to ensure the normal operation of the machine. ※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool for help.

Fault phenomenon:

A factory's motor motor rotor automatic three-station fine-turning machine in the normal operation of a period of time, suddenly appeared motor stop rotating, fine-turning machine control system display shows the motor drive failure alarm message, while the equipment's operating panel on the part of the function buttons failed to work, can not be manually operated in case of emergency.

Troubleshooting process:

1. first check the power supply part, found that the power indicator light is normally on, use the multimeter to measure the power supply voltage, three-phase power supply voltage are in the normal range, to rule out power supply problems.

2. As the alarm suggests that the motor drive failure, open the electrical control cabinet, check the motor drive. Found that the motor drive cooling fan does not turn, and drive shell temperature is high, initially suspected that the drive overheating caused by the protection action. 3.

3. further check the motor and its connecting lines, the use of insulation resistance meter to measure the insulation resistance of the motor winding, the results show that the motor winding insulation is good. Check the connection cable between the motor and the drive, no obvious damage, broken or short-circuit phenomenon. 4.

4. Check the fault record parameters of the drive, found that there is an overcurrent fault code. Considering that there is no problem with the motor itself and the connection is normal, it is presumed that there may be an abnormality on the load side causing the motor current to be too large. Check the tool cutting part of the fine-turning machine, found that the tool in the machining process occurred in the collapse of the edge phenomenon, resulting in an instantaneous increase in cutting resistance, causing the motor overload, which in turn makes the motor driver due to overcurrent and enter the protection state.

Solution:

1. replace the damaged tool, and check and adjust the installation and clamping of the tool to ensure that the tool is firmly installed and the cutting parameters are set reasonably.

2. cool down the motor drive, wait until its temperature drops to the normal range, restart the drive and clear the fault alarm message.

3. check the line connection of the operation panel, found that there is a button connection line in the drive failure by electromagnetic interference appears loose, reconnect and fix the button line.

4. the overall debugging of the equipment, the first low-speed no-load running motor, motor and drive to observe the operating state, no abnormalities gradually increase the load and speed, until the equipment to return to normal production.

Through the above troubleshooting and solution implementation, the motor motor rotor automatic three-station fine turning machine back to normal operation, to protect the factory's production schedule.