What are the contents of pre-service training for employees of brushless motor motor automatic rotor dynamic balancing machine?

Brushless motor motor automatic rotor dynamic balancing machine staff pre-job training content usually covers theoretical knowledge, operating skills specifications, maintenance and other aspects, the following is the specific content:

1、Theoretical knowledge training

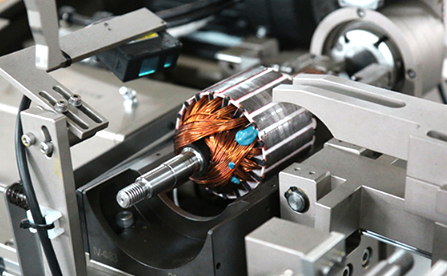

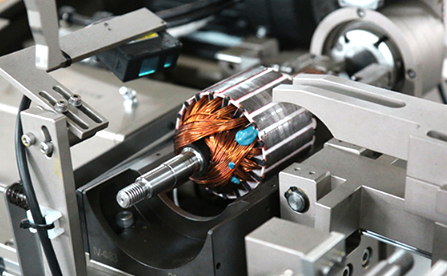

Brushless motor principle: explain the basic working principle of brushless motor, including the concepts of magnetic field, electromagnetic induction, electronic commutation, etc., so that the employees can understand the operation mechanism of brushless motor in order to better understand the role of dynamic balancing machine on brushless motor rotor.

Concept of dynamic balancing: Introduce the basic concepts of dynamic balancing, such as what is dynamic unbalance, the causes and hazards of dynamic unbalance, as well as the importance of dynamic balancing testing and calibration, so that employees can understand the significance and objectives of the work.

Working principle of equipment: elaborate the working principle of automatic rotor dynamic balancing machine, including the role of sensors, data acquisition and processing methods, and methods of balancing and calibration, so that employees can have a clear understanding of the working process of the equipment.

2、Operating skill training

Equipment operation interface: Familiarize with the functions and roles of buttons, knobs and displays on the operation panel, and master how to set parameters, start and stop the equipment, view and analyze measurement data through the operation interface.

Rotor clamping: Learn the correct rotor clamping methods and techniques to ensure that the rotor is not damaged during the clamping process and can be accurately mounted on the dynamic balancing machine to ensure the accuracy of measurement and calibration.

Parameter setting: Master the reasonable setting of parameters of the dynamic balancing machine according to different specifications and models of brushless motor rotors, such as rotational speed, measurement accuracy, balancing and calibration methods, etc.

Balance measurement and correction: Operate the dynamic balancing machine to carry out rotor balance measurement, learn to read and analyze the measurement data, and carry out balance correction operation according to the data, such as adding or removing counterweights, etc., until the rotor reaches the specified balance accuracy.

3、Training on standardized operation

Equipment prevention: Understand the standardized operation of the equipment, such as prohibiting touching the rotating parts during the operation of the equipment, avoiding forcible operation when the equipment fails, etc., so as to prevent the equipment from being damaged due to improper operation.

Personal protection: train employees how to properly wear personal protective equipment, such as protective eyewear, etc., emphasizing the work site to comply with the regulations, such as not running in the work area, jostling, etc..

Emergency response: learn the emergency response to common accidents, such as fire, electric shock and other accidents, master how to use fire extinguishers, first aid equipment, etc., to improve the staff's ability to deal with emergencies.

4、Maintenance training

Daily maintenance: train the staff to clean and check the contents and methods of the equipment before and after working every day or every shift, such as cleaning the dust on the surface of the equipment, checking whether the connecting parts of the equipment are loose, and so on.

Regular maintenance: Introduce the cycle and content of regular maintenance of equipment, such as regular replacement of lubricating oil, checking the accuracy of sensors, calibrating equipment, etc., so that employees understand the importance of regular maintenance on the performance and life of equipment.

Troubleshooting: Teach some common troubleshooting methods and techniques, such as how to check each part of the equipment step by step to find out the cause of the failure and take timely and appropriate measures to solve the problem when the equipment has abnormal vibration, inaccurate measurement data and other problems.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool to seek help.