When choosing the right winder manufacturer, you can consider the following key factors:

Clear requirements: First, you need to clarify your requirements, including the specifications of the winding machine, performance requirements, and budget. This helps to find the right winder on the market

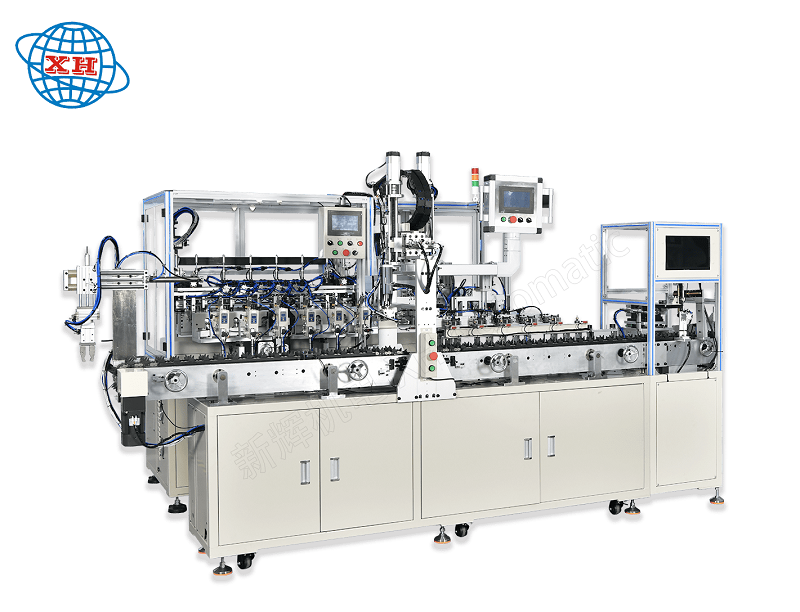

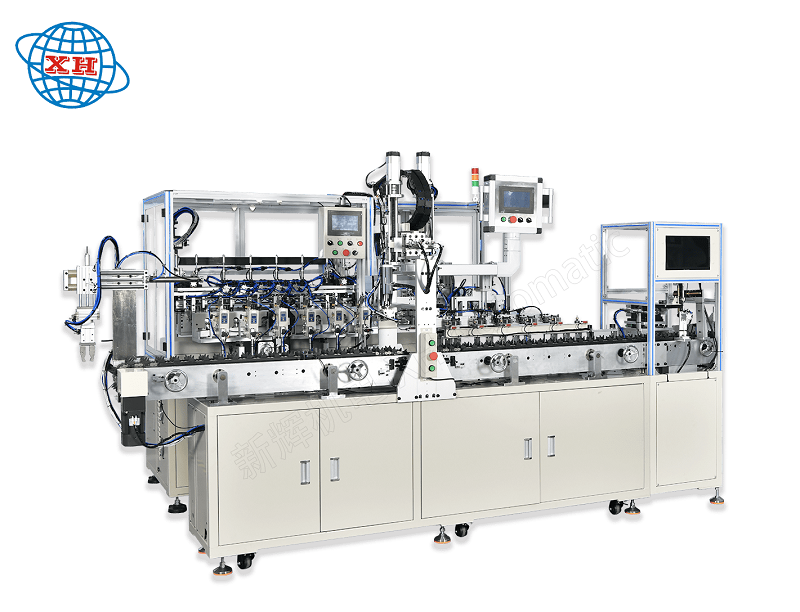

Understand the type of equipment: The winding machine mainly has three types: manual, semi-automatic and fully automatic. Choose the right type of equipment for your production needs and budget

Consider equipment performance: When selecting the winding machine, it is necessary to pay attention to its performance indicators, such as winding accuracy, speed, stability, etc., which will directly affect production efficiency and product quality

Check equipment brands and word-of-mouth: Select brands and equipment with a good word-of-mouth, these brands usually have a high level of product quality and after-sales service

Consider equipment maintenance and upgrade: When selecting the winding machine, you also need to consider the maintenance and upgrade of the equipment to meet the new production needs

Technology and innovation ability: Choose those manufacturers that have made breakthroughs in technological innovation, especially those that focus on the development of intelligent winding machines with a higher degree of automation

Market reputation and after-sales service: Investigate the manufacturer's market reputation and after-sales service ability, which is important to ensure the long-term stable operation of the equipment

Product performance and price comparison: Compare the product performance and price of different manufacturers, choose cost-effective winding machine

Site visits: If possible, site visits to the factory's production environment and technical level to ensure that it can meet your specific needs

Personalized customization services: Choose vendors that offer customization options to tailor your machine to your specific needs

Quality Assurance: Ensure that suppliers comply with strict quality control measures and ensure that their machines meet standards

Technology investment: Find suppliers that invest in research and development to provide machines with technology and functionality

After-sales support: A good supplier should provide after-sales support, including training, maintenance and spare parts supply

Engineer design ability: Select those engineers with the ability to design fully automatic winding machine manufacturers to ensure the rationality of the winding process and the stability of the equipment

Commissioning and trial production capacity: Select manufacturers that can debug and trial produce non-standard automation equipment to ensure that the performance indicators of the equipment meet or exceed the requirements