- Home

- About us

- Products

- DC Motor Automatic line

- Series Motor Automatic Line

- Automatic Core Punching Machine

- Automatic Endplate Commutator All-In-One Machine

- Automatic Servo Groove Paper Machine

- Automatic Six-Station Winding Machine

- Manual Six-Station Winding Machine

- Manual Four-Station Winding Machine

- Automatic Servo Slotting Machine

- Automatic Double Station High Frequency Spot Welder

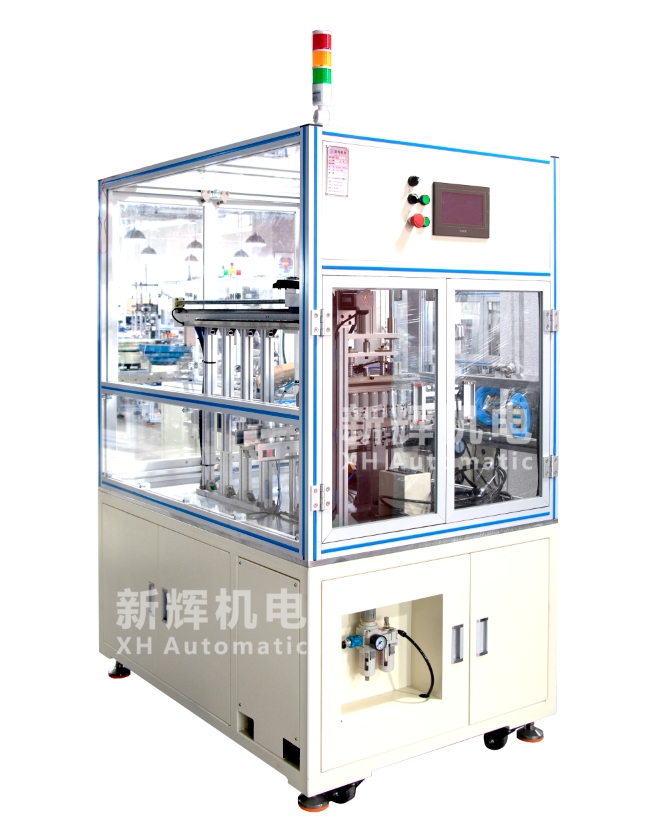

- Automatic Duplex Tester

- Automatic Double Knife Precision Turning Machine

- Visual Inspection Machine

- Automatic Rewinders

- Automatic Core Punching Machine

- Stator Stand-Alone Equipment

- Stator brushless equipment

- Non-Standard Equipment Spare Parts

- Motor Assembly Line

- DC Motor Automatic line

- Application

- Service

- News

- Contact us

- Home

- About us

- Products

- DC Motor Automatic line

- Series Motor Automatic Line

- Automatic Core Punching Machine

- Automatic Endplate Commutator All-In-One Machine

- Automatic Servo Groove Paper Machine

- Automatic Six-Station Winding Machine

- Manual Six-Station Winding Machine

- Manual Four-Station Winding Machine

- Automatic Servo Slotting Machine

- Automatic Double Station High Frequency Spot Welder

- Automatic Duplex Tester

- Automatic Double Knife Precision Turning Machine

- Visual Inspection Machine

- Automatic Rewinders

- Stator Stand-Alone Equipment

- Stator brushless equipment

- Non-Standard Equipment Spare Parts

- Motor Assembly Line

- Application

- Service

- News

- Contact us