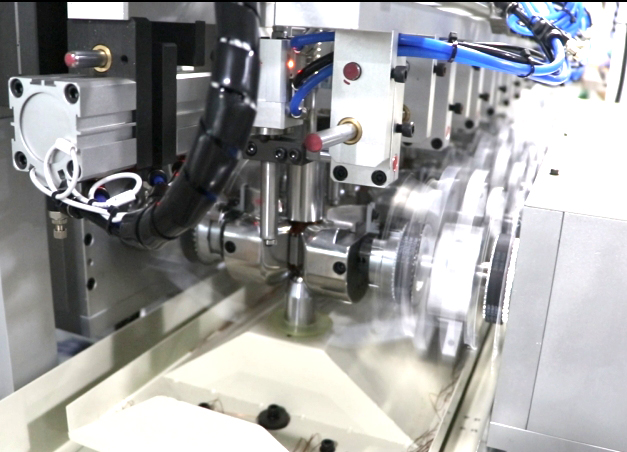

What are the common mechanical failures and solutions for motor motor rotor four-station double flying fork winding machine?

Motor motor rotor four-station double flying fork winding machine in the motor production line may encounter some common mechanical failures and their solutions are as follows:

1、 installation and commissioning process failure:

Failure phenomenon: in the process of installation and commissioning, there may be broken wires, skipped wires, injured wires and rows of wires are not aligned.

Solution: the need for professional and technical personnel to carry out installation and commissioning, in accordance with the instructions and their requirements, for different faults debugging elimination. If you do not understand the place, you can seek the merchants to solve the problem, most of the merchants have after-sales warranty services.

2、 the whole machine reset problem:

Failure phenomenon: the whole machine error caused by the instantaneous failure of the winding machine.

Solution: can be used to reset the hardware or sequentially switch the system power to eliminate the fundamental fault. If the system operates normally due to unstable voltage in the storage area, you must initialize the system and cut the undervoltage of the circuit board plug or rectifier switching power supply. Before cutting the root, note the current data backup record. If the fault still can not be solved after resetting the initialization, please perform the hardware replacement diagnosis.

3、Error in parameter setting:

Fault phenomenon: Incorrect setting of certain winding parameters may lead to system failure or invalid function.

Solution: Use the Ready to Test operating procedure to check and correct user program errors to ensure proper operation.

4、 Improper adjustment of adjustable components:

Fault phenomenon: For example, the winding tension, shielding voltage and the starting position of the cable rack is not properly adjusted.

Solution: Some harmless faults can be corrected by adjusting the adjustable components.

5、Spare parts replacement method:

Failure phenomenon: In the maintenance of the winding machine, you may come across parts that need to be replaced.

Solution: Use complete spare parts to replace suspected faulty components. After the maintenance personnel to determine the cause of the failure, you can use this method to quickly diagnose the fault scale and winding. Winding machine quickly into normal operation, and then return to the damaged parts.

6、 improve the environmental quality of the method:

Failure phenomenon: environmental factors may lead to winding machine failure.

Solution: Improve the working environment of the winding machine, reduce dust, humidity and other unfavorable factors on the equipment.

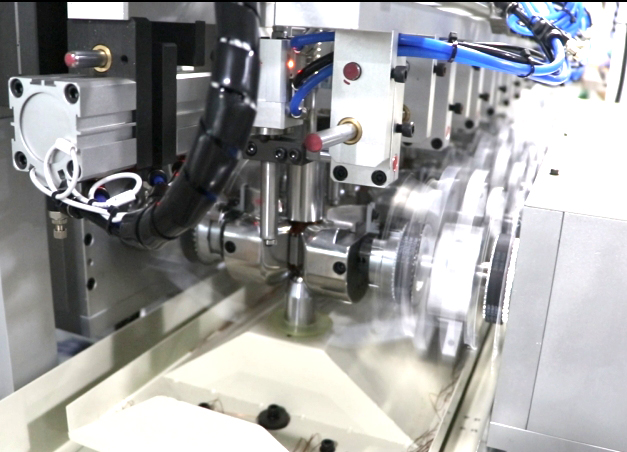

7、Mechanical failure:

Failure phenomenon: rotor jamming, rotor sweep and motor vibration and other faults.

Solution: by adjusting and correcting the motor mounting position, re-calibrate the motor axis line, maintenance or replacement of bearings and other methods to be resolved.

8、 electromagnetic failure:

Failure phenomenon: core failure and winding failure, such as rotor cage bar breakage failure and stator winding failure.

Solution: check the cage motor rotor manufacturing process, material quality, starting frequency and impact strength, as well as the stator winding disconnection, grounding, short-circuit and first and last end connection error.

The above are some common mechanical failures and their solutions that may be encountered by the motor motor rotor four-station double flying fork winding machine. For different failure phenomena, corresponding inspection and maintenance measures should be taken to ensure the normal operation and production efficiency of the equipment.

※ If through the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool to seek help.