What are the common mechanical failures and solutions for brushless motor motor manual stator slot paper machine?

Brushless motor motor manual stator slot paper machine common mechanical failures and solutions are as follows:

First, the paper feeding mechanism failure

1, paper delivery is not smooth

Fault description: paper in the conveying process appears stuck, stagnant or skewed phenomenon, affecting the normal processing of slot paper.

Solution: Check whether the paper feed roller wear or surface dirt, such as wear and tear need to be replaced in a timely manner, there is dirt is clean; adjust the pressure of the paper feed roller to ensure that the pressure is uniform and moderate; check whether the paper is deformed by moisture, such as the problem of replacing dry, flat paper.

2, inaccurate length of the paper feed

Fault Description: The length of the paper sent out does not match the set value, resulting in inconsistent stator slot paper size.

Solution: Check the transmission components of the paper feeding mechanism, such as gears, chains, etc., whether there is loose, wear, if there is a problem with fastening or replacement; calibrate the encoder of the paper feeding motor to ensure accurate control of the length of the paper; adjust the parameter settings of the paper feeding mechanism, such as feeding speed, acceleration, etc., in order to achieve the purpose of accurate paper feeding.

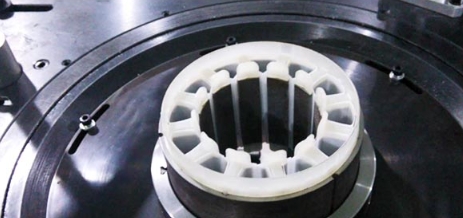

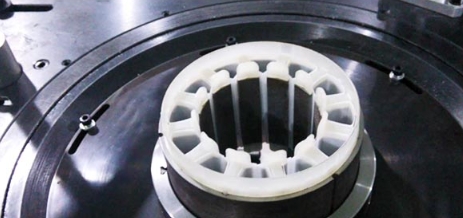

Second, the stator slot molding mechanism failure

1、Slot shape is not regular

Fault description: The shape of the stator slot is irregular, such as crooked, wide and narrow, affecting the quality of the motor stator.

Solution: Check whether the molding die is worn, deformed or not firmly installed, such as wear or deformation need to replace the mold, installation is not firm, then re-tighten; adjust the pressure and position of the molding mechanism to ensure that the mold in the molding process, uniform force, accurate position; check the hardness of the material and the thickness of the material to meet the requirements, such as the replacement of the problem of the appropriate material.

2、Slot depth inconsistency

Fault description: The depth of the stator slot is not uniform, resulting in difficulty in embedding the winding or affecting the performance of the motor.

Solution: Check the wear and tear of the molding tool and replace it promptly if there is any wear and tear; adjust the cutting depth and feed speed of the tool to ensure that the cutting process is stable and accurate; check the mechanical transmission system of the equipment, such as screws, nuts, etc. whether there is any gap or wear and tear, and if there is any problem, adjust or replace it.

Third, the paper pressure mechanism failure

1、Insufficient pressure paper strength

Fault Description: The paper pressure mechanism can not be firmly pressed paper, resulting in paper displacement in the process, affecting the quality of grooved paper.

Solution: Check whether the paper pressure spring fatigue, damage, if any problems with the replacement of springs; adjust the pressure of the paper pressure cylinder to ensure that the paper pressure is sufficient; check whether the paper pressure roller or pressure plate is worn, if any wear and tear for replacement or repair.

2, uneven paper pressure

Fault Description: paper in the width direction of the paper pressure is inconsistent, appearing on one side of the pressure is tight on the other side of the pressure is loose.

Solution: Adjust the parallelism of the pressure roller or pressure plate to ensure that it is uniformly contacted with the paper plane; check whether the installation position of the pressure mechanism is correct, if there is any deviation to adjust; the pressure mechanism of the various parts of the inspection and maintenance to ensure that it works properly.

Fourth, the transmission mechanism failure

1, belt slippage

Fault description: belt slippage in the transmission process, resulting in unstable power transmission, abnormal equipment operation.

Solution: Check the tension of the belt, adjust the tensioning wheel to make the belt tension moderate; check the belt surface whether there is oil, wear and tear, such as oil cleaning, wear and tear of serious replacement of the belt; check whether the pulley is worn or not parallel to the installation, if there is a problem with the repair or adjustment.

2、Chain jamming

Fault description: The chain is stuck and jumping teeth in the transmission process, which affects the normal operation of the equipment.

Solution: Clean the oil and impurities on the chain, lubricate the chain regularly; check the tension of the chain and adjust the chain tensioning device; check whether the sprocket is worn, deformed or not firmly installed; if there is any problem, replace or fasten it.

※ If you still can't solve the problem by the above ways and means, please contact the technical specialist of Xinhui Mechanical & Electrical Equipment Co.