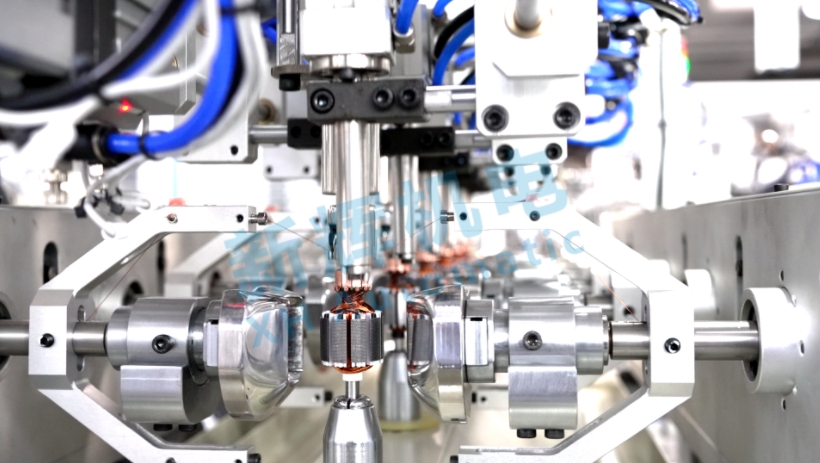

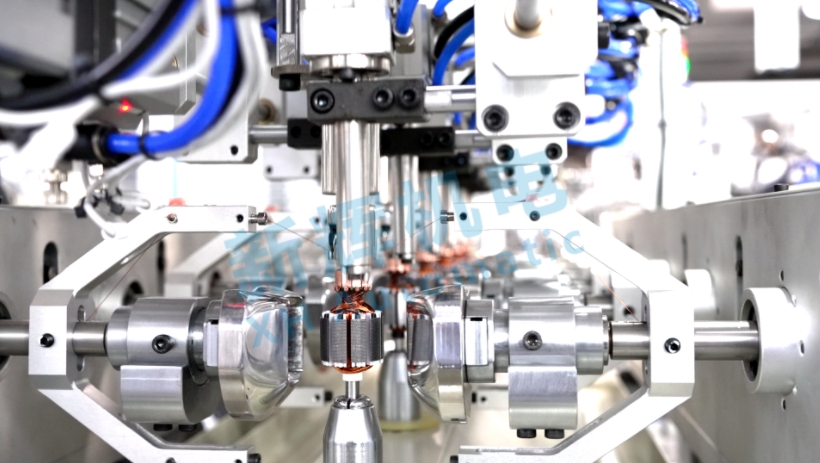

What are the common electrical faults and solutions for motor motor rotor automatic six-station double flying fork winding machine?

Motor motor rotor automatic six-station double flying fork winding machine has the following common electrical faults and solutions:

1, power failure

Failure phenomenon: the machine can not start, the power indicator does not light.

Possible causes: the power plug is not plugged in or the power cord is damaged; power switch failure; fuse blown; power input voltage is abnormal.

Solution: check whether the power plug is plugged in tightly, try to replace the power cord; check whether the power switch is working properly, if there is a problem, replace it in time; check the fuse, if it is blown, replace it with the same specification; use a multimeter to measure the power supply input voltage to ensure that it is within the rated range, such as the voltage is abnormal, you need to check the power supply line or use a voltage regulator.

2、Control system failure

Failure phenomenon: the machine appears to be dead during operation, the program is chaotic or can not properly execute the set winding program.

Possible causes: control system hardware failure, such as damage to the control chip, circuit board short circuit, etc.; control system software errors or vulnerabilities; external interference signals affect the normal operation of the control system.

Solution: for hardware failures, professional maintenance personnel need to use testing tools to detect the hardware, to determine the faulty parts for replacement; for software problems, try to restart the device, if the failure persists, you can update the control system software or restore the factory settings; for external interference, you should check the equipment around the large electromagnetic equipment and other sources of interference, to take effective shielding measures, such as increasing the shielding cover, grounding wire, etc., while checking the external interference signals affect the normal operation of the control system. For external interference, check whether there are large electromagnetic equipment and other sources of interference around the equipment, and take effective shielding measures, such as increasing the shielding cover, grounding wire, etc., and check whether the equipment is well grounded.

3、Motor failure

Failure phenomenon: the motor does not rotate, abnormal speed or rotation with abnormal sound.

Possible causes: motor winding short circuit, disconnection or grounding; motor drive failure; motor bearing damage; motor overload or phase failure operation.

Solution: use insulation resistance meter and multimeter to check the insulation resistance and resistance value of the motor winding to determine whether there is a short-circuit, disconnection or grounding fault, if there is a problem should be timely replacement of the motor winding or motor; check the working status of the motor drive to see whether there is an alarm prompt, if there is a failure according to the prompts need to carry out the appropriate processing or replacement of the drive; check the motor bearings, such as wear and tear or damage, should be replaced in a timely manner; check the motor load, check the speed abnormalities or abnormal rotation of phase missing operation. Should be replaced in a timely manner; check the motor load, to avoid overload operation, while checking whether the power supply is out of phase, to ensure that the motor is normally powered.

4、Sensor failure

Failure phenomenon: the counting of the winding machine is inaccurate, positioning deviation or failure to detect the relevant signals.

Possible causes: sensor damage or aging; sensor installation position is not appropriate; sensor and the control system between the connection line is loose or broken.

Solution: Check the appearance of the sensor whether there are signs of damage, if damaged, then replace the same type of sensor; adjust the sensor's installation position to ensure that it can accurately detect the corresponding signal; check the sensor and the control system between the connecting line, re-plugging or welding loose connectors, repair the broken line.

5, line connection failure

Failure phenomenon: intermittent failures in machine operation, unstable signal transmission or failure of some functions.

Possible causes: electrical lines in the plug, socket loose or poor contact; wire aging, damage caused by short-circuit or disconnection; loose or oxidized terminals .

Solution: carefully check all the plugs and sockets to ensure that they are firmly connected, for the loose plugs and sockets for re-plugging or replacement; check whether the insulation of the wire is broken, aging phenomenon, if there is a problem should be replaced in a timely manner; check the connection of the terminals, tighten the loose terminals, remove the oxidized layer, to ensure that a good electrical connection.

6、Failure of frequency converter

Failure phenomenon: motor speed instability, unable to reach the set speed or overcurrent, overvoltage and other alarms.

Possible causes: inverter parameters are not set properly; inverter heat dissipation leads to overheating protection; inverter internal electronic components are damaged; input and output line failure.

Solution: Check the parameter setting of the frequency converter, and make reasonable adjustments according to the characteristics of the motor and the load; ensure that the frequency converter has good heat dissipation, clean up the dust on the radiator, and check whether the heat dissipation fan is functioning normally; for the case of damage to the internal electronic components, the frequency converter needs to be repaired or replaced by a professional; check the input/output lines, and exclude the line faults.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool to seek help.