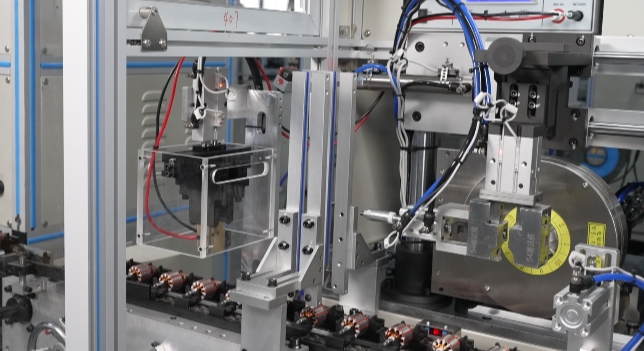

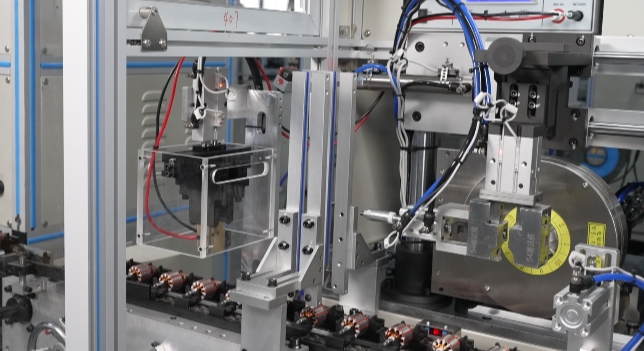

What are the common electrical faults and solutions for motor motor rotor (single station) automatic testing machine?

Motor motor rotor (single station) automatic test machine common electrical faults and solutions include:

1, the machine does not respond: If the switch does not respond to the machine, it may be due to incorrect wiring, the power supply is not open. The solution is to change the wiring, close the main power switch.

2, the electrode does not move: the power can start, but the electrode does not move, may be due to not connected to the gas source, air pressure problems, air leakage, solenoid valve wiring error or disconnect, solenoid valve bad. The solution is to connect the air source, check the air pressure meter, change the air tube, connect the solenoid valve line or replace the electromagnetic valve.

3, current malfunction: fault display current malfunction, the possible causes are secondary short circuit, incorrect connection or component damage. The solution is to exclude the short circuit, notify the manufacturer.

4, the network pressure is too high or too low: the fault shows that the network pressure is too high or too low, the possible causes are fluctuations in the power grid. The solution is to check the power grid and wait for normal.

5、Output current is limited: the fault shows that the output current is limited and cannot reach the set value, the possible reason is that the load or circuit resistance is too large and the current cannot reach the set value. The solution is to check the output circuit, reasonable configuration; reduce the current setting.

Case Description:

Frequent electrical faults occur in automatic testing machine, resulting in test work being obstructed.

Fault phenomenon:

No response after the test machine is started.

The current is unstable during the test, affecting the test results.

The tester occasionally stops automatically.

Failure cause analysis and solution:

Power supply problem:

Problem: The power supply line of the automatic tester may have poor contact or unstable voltage.

Solution: Check the power supply line to make sure that it is firmly connected and use voltage stabilizing equipment to ensure that the voltage is stable.

Sensor failure:

Problem: The sensor used in the automatic testing machine may be faulty, resulting in inaccurate test data.

Solution: Regularly calibrate the sensor and replace it in time when abnormalities are found.

Controller Failure:

Problem: The controller of the automatic testing machine may be faulty, resulting in the machine not operating normally.

Solution: Check the circuit board of the controller to confirm whether any components are damaged and make necessary repairs or replacements.

Through the above solution, the electrical failure of the automatic testing machine was successfully eliminated, and normal testing work was resumed, ensuring the accuracy and reliability of the performance test of the motor rotor.

※ If you still can't solve the problem by the above ways and means, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool to seek help.