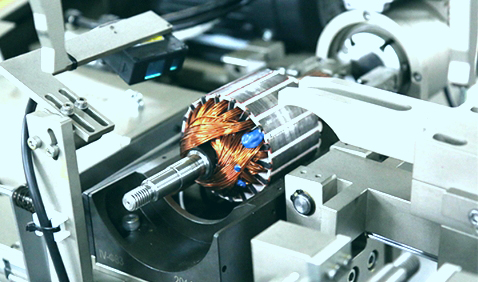

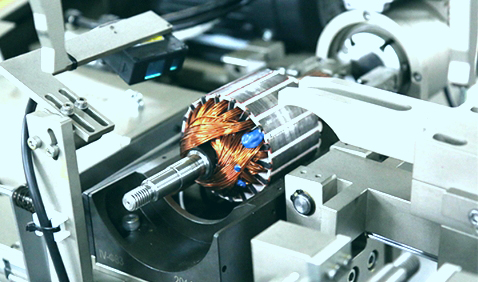

What are the common electrical faults and solutions for motor motor rotor automatic balancing machine?

Motor motor rotor automatic balancing machine common electrical faults and solutions are as follows:

1、Sensor failure

l Failure phenomenon: sensor no output signal or unstable output signal

l Cause analysis:

Sensor internal line short circuit, broken circuit and other damage conditions .

Sensor connecting rod bending or blocking, affecting the signal transmission.

Loose sensor installation, resulting in inaccurate signal acquisition.

l Solution:

Use a multimeter to check the sensor line, if there is damage, replace the sensor or repair the line.

Calibrate the bent connecting rod to ensure smooth movement.

Tighten the loose sensors to ensure that the installation is firm and stable.

2、Inaccurate speed measurement

l Trouble phenomenon: the balancing machine shows no speed or too large a change in speed

l Cause analysis:

For the photoelectric sensor to detect the rotational speed of the balancing machine, it may be the reflective paper off, the engraved line is covered by dust, or the distance between the photoelectric head and the reflective paper is not appropriate.

The transmission belt is loose or slipping, resulting in unstable rotor speed.

The magnetoelectric sensor is damaged or the relative position with the sensing parts on the spindle is not suitable, which affects the acquisition of rotational speed signal.

Frequency converter interference, resulting in abnormal rotational speed signal.

l Solution:

Clean or replace the reflective paper, readjust the distance between the photoelectric head and the reflective paper to make it meet the requirements.

Tighten or replace the drive belt to ensure that the rotor speed is stable.

Replace the damaged magnetoelectric sensor, or adjust its relative position to the spindle sensing parts.

Check and ensure that the frequency converter, microcomputer, motor and other ground connection is good, eliminate interference.

3, inaccurate measurement data

l Failure phenomenon: the measurement of the unevenness of the amount of error, the display value of the error is large, including angular error and amplitude errors

l Cause analysis:

Sensor precision decline or damage, affecting the accuracy of data collection

Improper calibration of the instrument, resulting in deviation of the measurement system.

Environmental factors interfere, such as vibration, temperature changes, electromagnetic interference, etc., affecting the measurement accuracy.

l Solution:

Replace the sensor with high precision and good performance

Carry out correct calibration operation of the balancing machine according to the requirements of the equipment manual.

Take measures such as installing vibration isolation devices, controlling the ambient temperature, using shielding equipment, etc., to reduce the impact of environmental interference on the measurement.

4、Data Recording Failure

l Failure phenomenon: Measurement data is not recorded or recorded abnormally.

l Cause analysis:

Failure of the recorder itself, can not record data normally

Loose data cable, poor connection, resulting in data transmission interruption.

Software failure, affecting the normal recording and storage of data

l Solution:

Replace the faulty logger

Check and tighten the data cable to ensure a reliable connection.

Restart the balancing machine or upgrade the software version, repair software failure

5、Electronic control system failure

l Failure phenomenon: the balancing machine can not start or automatically stop during the measurement process

l Cause analysis:

Power supply failure, such as not connected to the power supply, power supply voltage instability, etc.

Hardware components in the electronic control box is damaged, such as motherboard failure, etc.

Software failure, resulting in the system can not run normally or error commands

l Solution:

Check the power supply line to ensure that the power supply is normally connected and the voltage is stable, and repair the power supply failure.

Check the hardware in the electronic control box and replace the damaged hardware components.

Restart the balancing machine, or reinstall and upgrade the software to eliminate software failures.

※ If you still can't solve the equipment failure through the above ways and means, please contact the technical specialist of Xinhui Mechanical and Electrical Equipment Co.