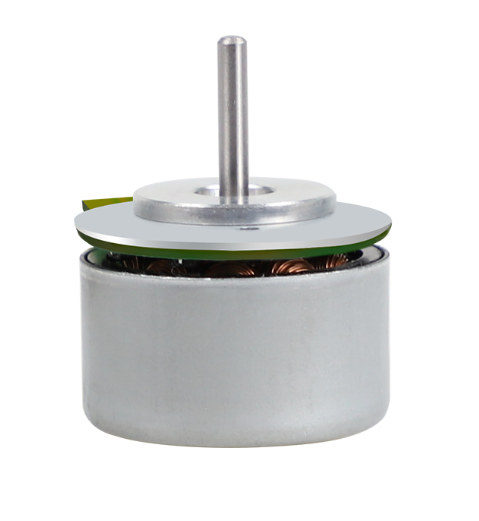

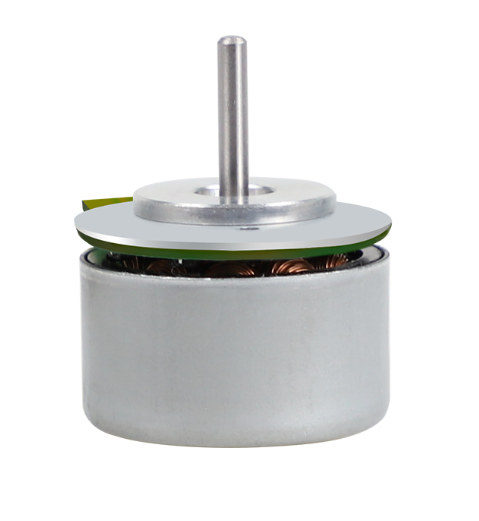

How to maintain the brushless motor motor automatic rotor shafting machine?

The following are the maintenance steps and points of the brushless motor motor automatic rotor shafting machine:

First, daily cleaning and inspection

1、Cleaning:

External cleaning:

Regularly use a clean rag to wipe the shell of the equipment, clear off the surface of the dust, oil and debris, to prevent it from entering the interior of the equipment, affecting the performance and life of the equipment. Focus on cleaning the operation panel, display, control cabinet and other parts of the shaft entry machine to ensure that the operator can clearly view and operate the equipment.

For the mechanical parts of the equipment, such as conveyor belts, chains, shaft entry mechanisms, bins, etc., clear away dust and debris from their surfaces to prevent dust from entering the transmission parts or affecting the normal operation of the sensors.

Internal cleaning:

For the electrical components inside the control cabinet, use compressed air or special electrical cleaners to clean and remove dust from circuit boards, PLCs, relays, contactors and other components to prevent short circuits or poor heat dissipation due to dust accumulation.

Clean the heat sinks and vents of the motor to ensure good heat dissipation and avoid affecting the normal operation of the motor due to heat dissipation problems.

2.Inspection:

Appearance check:

Check whether the appearance of the equipment is damaged before starting the machine every day, such as whether the shell is cracked or deformed, check whether the connecting parts of the equipment are loose, especially the mechanical connecting parts, such as bolts and nuts, etc., and tighten the loose parts in time to ensure the structural stability of the equipment.

Check whether the protective devices of the equipment are intact, such as guardrails, protective doors, etc., to ensure that they can normally play a protective role to prevent personnel injury and equipment damage.

Electrical inspection:

Check the appearance of the electrical wiring to see if the wires are broken, aging or the insulation layer is falling off, especially the wiring connecting motors, sensors, and controllers, and replace the wires with hidden dangers in time.

Check the connection of electrical equipment, including whether the plug is firm, whether the terminal is loose, to ensure that the electrical connection is reliable, to prevent electrical failures caused by poor contact.

Second, the maintenance of mechanical components

1, transmission components:

Conveyor belts and chains:

Regularly check the tension and wear of the conveyor belt, for the conveyor belt, if there is slack, adjust the tensioning device; if there is serious wear, replace the conveyor belt in time.

Check the tension and links of the chain, lubricate the chain to prevent the chain from rust and wear. If the chain links are found to be loose, deformed or badly worn, the chain should be repaired or replaced to ensure the accuracy and stability of the transmission.

Into the shaft mechanism:

Check the wear and tear of the shaft entry tools (such as press-fit head, fixture, etc.), and for the seriously worn shaft entry tools, they should be replaced in time to ensure the accuracy and quality of the shaft entry.

Check the guide rails, sliders and other moving parts of the shaft entry mechanism, clear away the dust and debris on the guide rails, and add the right amount of lubricant to ensure the smooth operation of the moving parts and avoid the phenomenon of stagnation.

Material bin:

Clear the residual material in the silo to prevent material accumulation and blockage. Check whether there is any deformation or damage to the structure of the silo, especially the outlet of the silo and the internal guiding device, to ensure that the material can enter the shaft flow smoothly.

For the silo with vibration device, check the operation of the vibration motor, including the vibration frequency, amplitude is normal, check whether the vibration motor is firmly installed, if necessary, adjust or replace the vibration motor parts.

2, bearing maintenance:

Check the running status of all kinds of bearings in the equipment, such as motor bearings, support bearings of transmission parts. Listen to whether there is abnormal sound when the bearing is running, touch the bearing parts with your hands, feel whether the temperature is too high. If there is abnormal sound or high temperature, it may be bearing wear or poor lubrication, should add or replace the grease. For serious wear and tear of the bearing, should be replaced in a timely manner to ensure the mechanical properties of the equipment.

Third, the maintenance of electrical components

1、Motor maintenance:

Regularly check the running status of the brushless motor, use multimeter, clamp ammeter and other tools to measure the voltage, current and speed of the motor to ensure that it is within the normal range. If the motor is abnormal, such as excessive current, unstable speed or overheating of the motor, the motor's windings, bearings and heat dissipation system should be further checked.

Check the motor's junction box to ensure that the wiring is secure to prevent motor failure due to poor contact. Clean the dust on the motor's junction box and windings to ensure the electrical performance of the motor.

2, sensor maintenance:

For position sensors, proximity sensors, pressure sensors, counting sensors and other types of sensors, clean their sensing head and detection surface to avoid dust, oil and dirt to affect their sensing performance.

Regular use of test tools to check the performance of the sensor to ensure that the output signal of the sensor is normal. If the sensor signal abnormality or failure, according to the type of failure to repair or replace, to ensure that the automation control of the equipment is normal.

3, control unit maintenance:

PLC maintenance:

Check whether the input and output signals of PLC are normal, and use PLC programming software for online monitoring to check the operation of the program. Check the input and output modules of PLC to ensure that the modules can receive and send signals normally.

Backup the program and parameters of the PLC regularly to prevent the program from being lost or damaged. At the same time, check the battery of the PLC, if the battery is low, replace it in time to prevent program loss.

Controller maintenance:

Check whether the display interface of the controller displays information normally, if display abnormality occurs, check the display module and connecting lines of the controller.

Check whether the control parameters of the controller are correct, and make backups of important control parameters to ensure that the parameters will not be lost or modified due to accidents.

Software Maintenance

1, software updates:

Regularly check whether there is an updated version of the software, according to the equipment manufacturer's recommendations or software update tips, update the software in a timely manner to obtain new features and repair known software vulnerabilities.

Before updating the software, backup the important parameters and programs of the device to ensure that it can be restored to the original state when the update fails. After updating the software, test all the equipment to ensure that the software update will not affect the normal operation of the equipment.

2、Software inspection and debugging:

Regularly check the setting parameters of the software to ensure that the parameters meet the operational requirements of the equipment. For some parameters adjusted according to the production task, such as the speed of the entry shaft, pressure parameters, etc., check whether their settings are correct.

Test the operation of the software and check whether the software can normally receive and process the signals from the sensors and whether it can correctly send control signals to the actuator. If abnormal operation of the software is found, check the error log of the software and debug and modify the software.

V. Lubrication and cooling system maintenance

1, lubrication system:

Check whether the lubrication system of the equipment is working properly. For the centralized lubrication system, check the operation of the lubrication pump to ensure that it can provide lubrication for the key components of the equipment on time and in quantity.

Replenish or replace the lubricant or grease according to the use of the equipment and running time. Different parts use different lubricants, to ensure that the lubricant used meets the requirements of the equipment, to avoid damage to the equipment due to improper use of lubricants.

2. Cooling system (if any)

For the shaft entry machine equipped with a cooling system, check whether the pipeline of the cooling system is smooth and whether the coolant is sufficient. Check the working status of the cooling fan and cooling water pump to ensure that the cooling effect of the equipment is good and prevent the equipment from being damaged due to overheating.

Regularly clean the radiator of the cooling system, clear away the scale or impurities in the cooling pipes to improve the cooling efficiency.

Sixth, regular calibration and adjustment

1, mechanical calibration:

Regularly calibrate the mechanical parts of the equipment, such as the position of the shaft entry mechanism, the position and angle of the silo, the position of the conveyor belt, etc. Use professional measuring tools to ensure the accuracy of their position and angle to ensure the accuracy of the shaft entry.

Calibrate the transmission parts of the equipment, adjust the speed of the conveyor belt and the transmission ratio of the chain to ensure that the speed and rhythm of the rotor into the shaft meet the production requirements.

2、Electrical calibration:

Calibrate the speed, torque and other parameters of the motor, and adjust the control parameters of the motor using test instruments to ensure that the motor can run stably under different loads.

Calibrate the sensors to ensure that the detection accuracy and sensitivity of the sensors meet the control requirements of the equipment, and adjust the parameters of the sensors according to the operation of the equipment, such as the detection position of the position sensors and the pressure threshold of the pressure sensors.

Through all of the above maintenance measures, you can ensure the long-term stable operation of the brushless motor motor automatic rotor into the shaft machine, improve the service life of the equipment and production efficiency, reduce the occurrence of failures.

If the above ways and means still can't solve the equipment failure, please contact Xinhui electromechanical technical specialists through the page chat tool to seek help.