What are some of the key elements of pre-service training for employees of brushless motor motor automatic rotor loading machine?

The following are some of the main contents of the pre-service training of brushless motor motor automatic rotor loading machine employees:

First, the basic knowledge of equipment

1, equipment overview:

Introduce the basic structure of the brushless motor motor automatic rotor loading machine, including silo, feeding mechanism, transmission system, control system and other major components, so that employees have a clear understanding of the overall layout of the equipment.

Explain the working principle of the equipment, so that employees understand how the rotor from the silo through the feeding mechanism, driven by the transmission system to complete the feeding operation, and how the various components work together to ensure that employees understand the logic of the operation of the feeding machine.

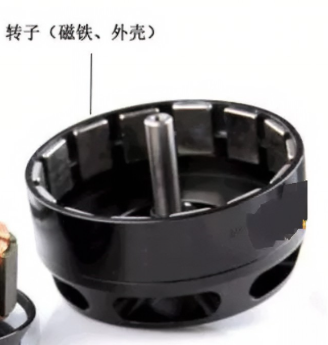

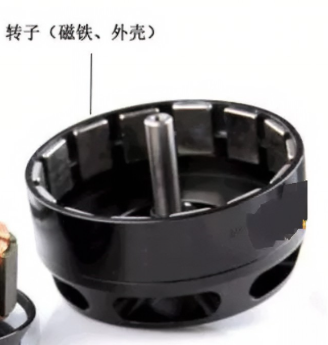

2、Brushless motor knowledge:

Explain the basic principles of brushless motors, such as the interaction of stator magnetic field and rotor magnetic field, and the advantages of brushless motors over traditional motors, so that employees can understand the importance and working characteristics of brushless motors in the feeding machine.

Explain the performance parameters of brushless motors, such as speed, torque, power, etc., and the impact of these parameters on the performance of the loading machine, to help employees master how to adjust the motor's working condition according to the production demand.

Second, operation skills training

1、Equipment operation process:

Detailed introduction to the feeding machine start-up and shutdown operation steps, including the inspection work before start-up (such as power supply, air source, equipment status check), the operation sequence when starting the machine (such as starting the power supply, start the control program, turn on the motor, etc.), and shutdown of the correct operation (such as stopping the loading action, shutting down the motor, shutting down the power, etc.), to ensure that the staff operating norms.

Explain the daily operation of the loading machine, including how to put the rotor into the bin, how to adjust the loading speed, how to deal with common problems in the loading process (such as clogging, jamming, etc.), as well as how to adjust the operating parameters of the equipment according to different rotor specifications and production tasks.

Train the staff how to use the operation panel of the equipment, including the operation of various buttons, displays, indicators and functional explanations, so that the staff can skillfully operate the operation panel for equipment control and monitoring.

2、Equipment maintenance operation:

Teach employees how to carry out daily maintenance, such as cleaning equipment, checking the wear and tear of mechanical parts, checking the connection of electrical wiring, etc., to cultivate employees' awareness and skills of daily maintenance.

Instruct employees to perform simple equipment maintenance operations, such as adding lubricant, replacing wear parts (such as conveyor belts, suction cups, etc.), and how to use tools for basic equipment adjustment and repair.

Third, protection knowledge training

1, protective operating procedures:

Emphasize the importance of protective operations, develop detailed protective operating procedures, including the use of equipment protection devices (such as guardrails, emergency stop button, etc.) and precautions to ensure that employees always keep in mind the protection of the operating process.

Train employees on how to identify and avoid common hidden dangers, such as preventing hand pinching, preventing electric shock, preventing risks of entanglement, etc., so that employees can master the protective measures in the process of equipment operation and maintenance.

2、Emergency handling procedures:

Teach employees emergency handling methods in case of equipment failure or emergencies, such as encountering sudden power outages, abnormal operation of equipment, fire, etc., including how to press the emergency stop button, how to cut off the power supply, and how to use a fire extinguisher.

Emergency drills are conducted to familiarize employees with the emergency handling process and ensure that they can act quickly and correctly in emergencies to reduce the occurrence of accidents and losses.

Fourth, quality control training

1、Quality requirements for loading:

Clarify the quality standards of the loading process, such as the accuracy of the loading position of the rotor, the stability of the loading speed, the accuracy of the loading quantity, etc., so that employees understand the impact of their work on the quality of the loading.

Train employees how to carry out quality checks, such as checking whether there is damage to the rotor after loading, whether the loading position is in line with the requirements, etc., so that employees have the awareness and ability to quality control.

V. Troubleshooting training

1、Common fault identification:

Introduce the feeding machine common failure phenomena, such as mechanical failure (such as transmission parts failure, feeding mechanism failure), electrical failure (such as sensor failure, motor failure), software failure (such as program errors, communication failures), etc., so that employees can learn to observe and determine whether the equipment failure.

Teach employees how to quickly determine the general scope of the fault through the equipment alarm information, abnormal sounds, abnormal phenomena, etc., to improve the staff's fault identification capabilities.

2. Troubleshooting methods:

For common failures, provide simple troubleshooting methods, such as how to repair simple mechanical failures, how to check the wiring and replace components for electrical failures, how to try to restart the program for software failures or adjust the software parameters, etc., so that the staff can solve the problem on their own when encountering simple failures and reduce downtime.

Sixth, teamwork and communication

Emphasize the importance of teamwork, especially in the process of equipment operation, maintenance and troubleshooting with other departments (such as maintenance department, quality control department, production management, etc.), so that employees understand their roles and responsibilities in the entire production team.

Train employees how to accurately report equipment failures and problems to their supervisors or maintenance personnel, including the description of the failure, the time of appearance, phenomena and other information to ensure the accurate transmission of information and improve the efficiency of troubleshooting.

Through all of the above pre-service training content, employees can have a more systematic understanding of the brushless motor motor automatic rotor loading machine, master the operation, maintenance, quality control and other aspects of the skills, for the smooth operation of the work and to ensure the smooth progress of production to lay a good foundation.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for help.