What is the content of the pre-service training for employees of brushless motor motor automatic rotor into magnet steel machine?

The following are the details of the pre-service training for employees of the brushless motor motor automatic rotor into the magnet steel machine:

First, the basic knowledge of equipment

1, equipment structure and principle:

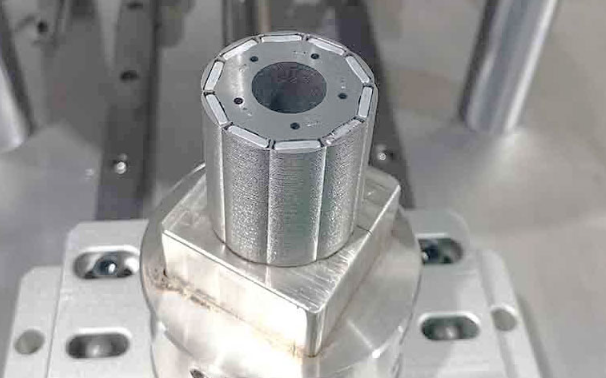

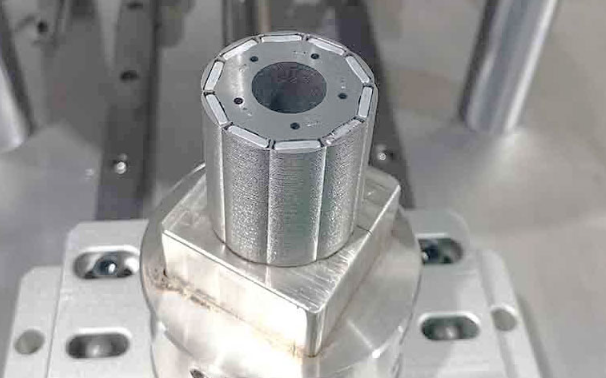

Introduce to the staff the overall structure of the brushless motor motor automatic rotor into the magnet steel machine, including the silo, transfer mechanism, into the magnet steel mechanism, drive system, positioning system, control unit and detection system and other parts. Use structural diagrams or physical displays of the equipment to give employees a clear understanding of the location, connectivity and function of each component.

Explain the working principle of brushless motors and how the rotor-in-magnet machine utilizes electromagnetic principles, mechanical transmission and automation control to achieve accurate magnet installation. Detailed elaboration of the workflow of the equipment, from the loading, transferring and positioning of the rotor and magnet, to the accurate installation of the magnet and the process of discharging the rotor, so that the employees have a clear understanding of the operating mechanism of the equipment.

Second, operation skill training

1、Equipment operation process:

Instruct employees on how to turn on and off the equipment correctly, including turning on the main power supply, checking the start-up status of the equipment, operating the power switch and emergency stop button on the control panel, as well as the order of operation and precautions when turning off the equipment.

Train employees to operate the equipment in the daily operating procedures, such as placing the rotor and magnet into the bin correctly, adjusting the operating parameters of the equipment according to different product specifications, such as the speed of entering the magnet, the magnet adsorption force, and the positioning accuracy, etc., and using the buttons and knobs on the operating panel to complete the operation.

Teach the staff how to operate the human-machine interface of the equipment, including how to view the operating status of the equipment, modify and set the parameters of the equipment, start and stop the operation of the magnet feeding steel, as well as how to deal with the pause and reset function of the equipment.

2、Equipment adjustment and maintenance operation:

Teach employees how to adjust the position and parameters of the magnet-entry mechanism according to different rotor and magnet sizes, such as the adjustment of the magnet-entry fixture and the parameter setting of the magnet adsorption device.

Cultivate the staff's ability to carry out simple maintenance on the equipment, such as cleaning the surface and internal parts of the equipment, adding lubricant or grease to the moving parts, checking and replacing the wearing parts, such as into the magnet steel tools, conveyor belts and so on.

Third, protection operation training

1、Protection awareness training:

Emphasize the possible risks when operating the brushless motor motor motor automatic rotor into magnet steel machine, such as mechanical injuries (e.g., pinching, risk of entrapment), electrical injuries (electrocution), and potential dangers of magnet steel adsorption (e.g., injuries caused by ejection of magnets), etc., by displaying the accident cases and the information such as pictures and videos.

Introduce the location and function of protective devices on the equipment, such as guardrails, light curtains, emergency stop buttons, etc., to ensure that employees know how to use these devices to protect themselves.

2. Protective operating procedures:

Explain in detail the protective operating procedures that must be observed when operating the equipment, such as wearing protective hats, protective shoes, protective gloves and goggles and other personal protective equipment.

Clearly in the operation and maintenance of equipment in the process of precautions, such as strictly prohibited in the operation of the equipment to adjust and clean up the work, are not allowed to touch the moving parts are running, shall not be arbitrarily dismantled protective devices, and so on.

Train employees in emergency response methods in case of emergency, including how to use the emergency stop button, how to cut off the power supply, how to deal with equipment anomalies (such as magnets stuck, equipment smoke, etc.), and carry out emergency drills to ensure that employees are familiar with the operating procedures.

Fourth, quality control training

1、Quality standard explanation:

Explain to employees the quality standards of the rotor into the magnet, such as the accuracy of the magnet's installation position, the magnet's adsorption firmness, the uniformity of the magnet's distribution, etc., so that employees understand the impact of their operations on product quality.

Teach employees how to use simple measuring tools (such as calipers, micrometers, etc.) to check the quality of the rotor into the magnet, and how to determine whether the product is qualified.

V. Troubleshooting training

1、Common fault identification:

Introduce the common failure phenomena of the equipment to the staff, such as mechanical failure (into the magnet steel mechanism failure, transmission component failure, bin blockage), electrical failure (motor failure, sensor failure, circuit failure), control failure (PLC program error, human-computer interface abnormality) and software failures (software operation error, communication failure) and so on.

Help employees learn to recognize the type and scope of faults by observing the operating status of the equipment, fault alarm messages, abnormal sounds and display information on the operation panel.

2、Simple troubleshooting methods:

For some common simple faults, such as silo clogging, conveyor belt slippage, sensor failure, etc., to provide the corresponding troubleshooting methods, such as how to clean up the silo, adjust the conveyor belt tensioning device, clean the sensor, etc..

Let employees understand how to report to the technician or supervisor when encountering unsolvable faults, accurately describing the fault phenomenon and possible causes, in order to promote the rapid resolution of the problem.

Sixth, teamwork and communication training

Let employees understand their roles and responsibilities in the production team, and how to collaborate with other team members (e.g., maintenance staff, quality inspectors, production schedulers).

Train employees how to accurately record equipment operation and operating information, fill out operating records and fault reports to ensure the accuracy and completeness of the information, so that effective information exchange and collaboration between team members.

Through all the pre-service training, employees can better master the skills of operation, maintenance, and quality control of the fully automatic rotor-in-magnet machine for brushless motor motors to ensure the normal operation of the equipment and the quality of the products.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.