What are the common mechanical failures and solutions for brushless motor motor automatic rotor into magnet steel machine?

The following is a brushless motor motor automatic rotor into the magnet steel machine common mechanical failure and the corresponding solution:

First, into the magnet steel mechanism failure

Failure phenomenon:

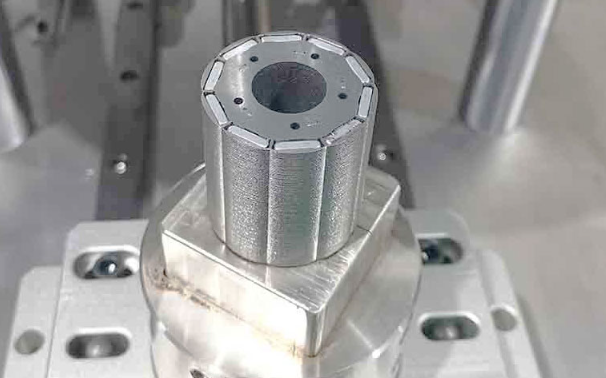

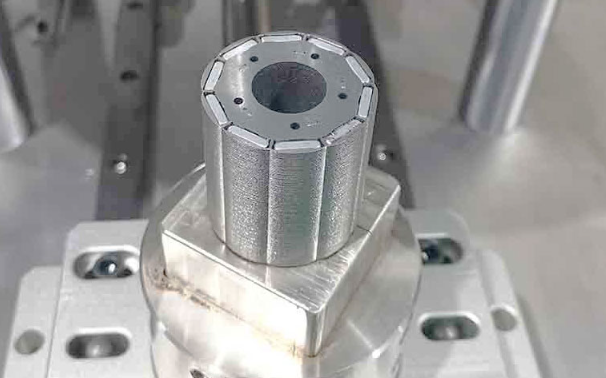

Into the magnet steel tool wear or damage: into the magnet steel tool (such as magnet clamps, press-fit head) in the frequent use of the process will be worn, affecting the magnet gripping and press-fit precision, and even can not firmly grasp the magnet, resulting in inaccurate magnet installation position or fall.

Into the magnet steel mechanism movement is not smooth: the mechanism of the guide rail, slider, cylinder or hydraulic cylinder and other components may be stagnant phenomenon, resulting in into the magnet steel action can not be completed accurately, affecting production efficiency and product quality.

Solution:

For the problem of the magnet entry tool, check its wear regularly and replace it with a new magnet entry tool in time according to the degree of wear. When choosing new tools, make sure their size, shape and material meet the requirements of the equipment, and pay attention to the hardness and strength of the tools. For some fragile magnetizing steel tools, a certain number of spare parts can be prepared.

When the movement of the magnetizing steel mechanism is not smooth, first of all, check the surface of the moving parts of the mechanism to see if there is any foreign matter, and clean up the dust, oil and debris on the guide rail, slider and other parts. At the same time, check the lubrication of these parts, add or replace the appropriate lubricant or grease in time. If the moving parts wear or deformation, such as guide rail wear, slider with too large a gap, should be replaced in a timely manner to ensure that the wearing parts, to ensure a good fit between the moving parts.

Second, transmission parts failure

Failure phenomenon:

Conveyor belt or chain failure: the conveyor belt may slip, run off or break, affecting the transmission and positioning accuracy of the rotor; chain may be loose, jumping teeth or fall off, resulting in the rotor can not accurately reach the position of the entry magnet.

Gear transmission failure: Gears may be worn, damaged or poorly meshed, resulting in inaccurate transmission ratios, affecting the rotational accuracy of the rotor and the accuracy of the operation into the magnet.

Solution:

For conveyor belt or chain failure, if the conveyor belt slips, the normal tension can be restored by adjusting the tensioning device; if it runs out of alignment, it is necessary to check the guiding devices of the conveyor belt, such as rollers and guide rails, and adjust their position and parallelism. For conveyor belt breakage, replace it in time and check whether its tensioning device and driving parts are normal. For chain, if it is loose, adjust the tensioner; if it jumps teeth, check the wear of chain and sprocket, and replace the parts with serious wear; when the chain falls off, reinstall and check the connection firmness and chain length.

For gear transmission failure, check the wear of gears, if the tooth surface wear is serious or appear damaged, need to replace the gear. At the same time, check the installation position and meshing of gears, adjust the center distance to ensure the correct meshing of gears and the accuracy of the transmission ratio.

Third, the silo failure

Failure phenomenon:

Bins clogging: magnets in the bin pile up, can not smoothly enter the magnet into the process, may be due to the bin structure is not reasonable, the material size mismatch or the material between each other caused by extrusion.

Silo discharging mechanism failure: the silo gate or discharging device can not be opened or closed properly, affecting the discharging speed and sequence of magnets, resulting in production interruptions or errors.

Solution:

For bin clogging, first stop the equipment and clean the clogged magnets, then check the structure of the bin, such as adjusting the inclination angle of the bin to make it more favorable for the discharging of magnets. For the size mismatch of magnets, consider screening the magnets or adjusting the silo structure to fit the material size. At the same time, you can add a vibration device or stirring device to prevent the magnets from clogging in the silo.

For silo discharge mechanism failure, check the drive components of the discharge mechanism, such as cylinder, electric actuator or mechanical linkage, to ensure its normal operation. Check whether the power supply and control signal of the driving parts are normal, and repair or replace the damaged parts. For the mechanical structure of the gate, check whether the guide rail, connecting rod and other parts are damaged, repair or replace them in time to ensure the normal opening and closing of the gate.

Fourth, the positioning device failure

Failure phenomenon:

Inaccurate positioning of the rotor: the positioning device may be worn out, deformed or shifted in position due to long-term use, resulting in the rotor not being able to be accurately positioned before entering the magnet, which affects the accuracy of the installation position of the magnet.

Stagnation of the moving parts of the positioning mechanism: the guide rail, slider or rotating parts in the positioning mechanism are stagnant, which makes the positioning action not smooth and affects the overall operating efficiency of the equipment.

Solution:

For the problem of inaccurate rotor positioning, check the positioning accuracy of the positioning device, calibrate it using a gauge, and repair or replace the worn or deformed positioning parts. Check the installation position of the positioning device to ensure that its positional accuracy meets the requirements.

For the moving parts of the positioning mechanism are stuck, clean up the debris and oil on the moving parts and add appropriate amount of lubricant or grease. Check the wear and tear of moving parts, for serious wear and tear of parts, such as guide rails, slider, timely replacement, to ensure smooth movement of the positioning mechanism.

Fifth, the mechanical connection parts failure

Failure phenomenon:

Loosening or falling off of connection bolts: During the operation of the equipment, the bolts of the connection parts may be loosened due to vibration, affecting the stability and accuracy of the equipment, which may lead to displacement or damage of the parts in serious cases.

Deformation or damage of connecting parts: such as bracket, frame and other parts may be deformed or damaged due to excessive force or long-term use, affecting the overall structure and function of the equipment.

Solution:

For loose or dislodged connection bolts, check and tighten the bolts regularly, especially the bolts in critical parts, you can use anti-loosening nuts or add spring washers to prevent loosening. If the bolts are found to have fallen off, reinstall and check the related parts for displacement and recalibrate the equipment.

For the deformation or damage of the connecting parts, repair or replace them according to the degree of deformation or damage. For the key connecting parts, make sure that their strength and stiffness meet the requirements of the equipment, and re-adjust the overall structure of the equipment and the positional accuracy of the parts after repairing or replacing them.

Through the identification and treatment of these common mechanical failures, you can effectively maintain the normal operation of the brushless motor motor automatic rotor into the magnet steel machine, improve the reliability of the equipment and production efficiency, to ensure product quality.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool to seek help.