What are the spare parts required for a fully automatic rotor shafting machine for brushless motors and how should I set up a guaranteed stock?

The following is a list of spare parts required for brushless motor-automatic rotor shafting machines and suggestions on how to set up a guaranteed stock:

I. Spare parts

1、Mechanical parts spare parts:

Transmission parts:

Conveyor belts and chains: conveyor belts and chains are important transmission parts, easy to wear, stretch or damage due to long-term use. Prepare 1-2 sets of spare conveyor belts and an appropriate number of spare chain links according to the frequency of use and load conditions of the equipment. For example, if the machine's belts are expected to be replaced every six months, have at least one spare set of belts, and 20-30 spare links for the chain, depending on the wear of the links.

Shafting tools (e.g., press-fit heads, fixtures, etc.): These components are subject to wear and tear from frequent shafting operations, affecting the accuracy and quality of the shafting process. Usually, it is necessary to prepare 3-5 sets of different sizes of shafting tools, including different sizes and shapes of press fitting heads and jigs, to meet the requirements of shafting different rotors and shafts.

Bearings: The motors, transmission components and some rotating mechanisms in the equipment rely on bearings, which are wearing parts. Depending on the size of the bearings used in the equipment, have 3-5 spares of each size available in case of damage due to bearing wear, overheating, or lubrication problems.

Guide rails and sliders: For the guide rails and sliders of the shaft entry mechanism, as they will wear out due to long-term movement, prepare 2-3 sets of spare guide rails and slider assemblies to ensure the smooth operation of the moving parts.

2. Silo components:

Silo gates and vibrators: If the silo is equipped with gates and vibrators, prepare 1-2 sets of spare gate assemblies and vibrator parts. Silo gate may be damaged due to frequent opening and closing, vibrator may be due to long-term vibration motor failure, spring damage and other problems, need to be replaced in a timely manner.

Silo structural parts: such as silo side plate, bottom plate, etc. may be deformed due to the impact of materials or long-term use, you can prepare a small number of silo structural parts as spare parts, such as 1-2 pieces of spare side plate or bottom plate.

3、Electrical parts spare parts:

Motor and its accessories:

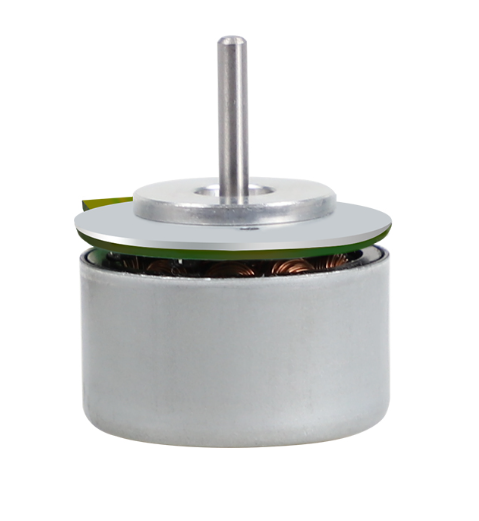

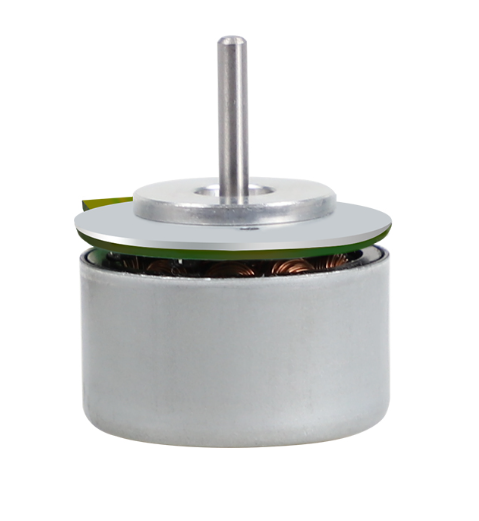

Prepare 1-2 spare brushless motors to cope with motor failure, such as winding damage, bearing failure or motor driver failure. At the same time, also need to prepare some motor accessories, such as motor fan, motor driver, motor junction box, etc., each kind of accessories can be prepared 2-3, to ensure the normal operation of the motor.

Sensors:

For position sensors, proximity sensors, pressure sensors and counting sensors, prepare 2-3 spares for each type of sensor. These sensors are susceptible to failure due to environmental influences, mechanical shocks, or their own aging, so ensure that they can be replaced in a timely manner in the event of a malfunction.

Relays and contactors:

Prepare 5-10 relays and contactors of different sizes, which are key components in control circuits and may be affected by frequent on/off operations resulting in contact erosion, spring deterioration, etc., affecting the normal on/off operation of the circuit.

Fuses and Circuit Breakers:

Prepare 5-10 fuses and circuit breakers for each specification, as an important component of the protection circuit safeguard, it will fuse or trip when there is an overload or short circuit, and need to be replaced in time.

4, control unit spare parts:

PLC module:

Prepare 1-2 spare PLC input modules and output modules to cope with module failures, such as damage to input and output points or module internal circuit failures.

Controller Components:

For the controller of the equipment, prepare some key parts, such as the power module, display module, operation buttons of the controller, etc. You can prepare 1-2 of each part according to the complexity of the controller and the frequency of failure.

Second, to ensure that the inventory set

1. Determine the consumption rate:

Through the use of equipment records and maintenance records, statistics on the average consumption of each spare part in a certain period of time (such as a month or a quarter). For example, if the records of the past six months show that a fuse is consumed on average every two months, then the monthly consumption rate of that fuse is 0.5. For each type of spare parts, the consumption rate should be carefully counted, including mechanical parts, electrical parts and control unit parts.

2. Consider the procurement cycle:

Communicate with suppliers to determine the procurement cycle for each spare part, that is, the time required from placing an order for procurement to receiving the goods. For spare parts with a long procurement cycle, it is necessary to appropriately increase the guaranteed inventory. For example, some special specifications of the sensor procurement cycle may be as long as 3 months, then you need to consider reserving enough for 3 months of use of the sensor as a guarantee stock.

3, set the level of guaranteed inventory:

Basic guaranteed stock:

Based on the consumption rate and procurement cycle to calculate the base guarantee stock, the formula is: guarantee stock = average consumption rate × procurement cycle. For example, a certain model into the shaft tool monthly consumption of 1 set, the procurement cycle for 1 month, then its basic guaranteed stock can be set to 1 set.

Consider the contingency factor:

On the basis of the base guaranteed stock, consider some contingencies, such as a sudden increase in the intensity of equipment use, fluctuations in the frequency of equipment failures, and delayed deliveries from suppliers. For critical spare parts, an additional 30%-50% margin can be added as the back guarantee stock. For example, for brushless motors, a 50% margin can be added on top of the basic guarantee stock to ensure that the equipment can still operate normally in case of emergency.

4、Inventory monitoring and adjustment:

Establish an inventory management system to regularly inventory and monitor the inventory of spare parts to ensure the accuracy of the inventory quantity. When the inventory quantity is lower than the guaranteed inventory, trigger the procurement process in time. At the same time, according to the use of equipment, equipment replacement and changes in the frequency of failures, adjust the quantity of guaranteed stock and the types of spare parts in due course to meet the maintenance and production needs of the equipment.

5、Vendor management:

Establish long-term and stable cooperative relationship with several reliable suppliers to ensure quick procurement of spare parts when they are needed. For important spare parts, an emergency supply agreement can be signed with the supplier to ensure that the supply can be prioritized in case of emergency. At the same time, we regularly evaluate the quality and service level of the suppliers to ensure that the purchased spare parts are of reliable quality and reasonable price.

By reasonably stockpiling spare parts and setting up a guarantee stock, we can effectively reduce equipment downtime, improve the reliability and production efficiency of the brushless motor motor automatic rotor into the shaft machine, and guarantee the smooth progress of production. In actual operation, according to the specific conditions of the equipment and changes in the production environment, we should flexibly adjust the level of spare parts reserves and safeguard inventory.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.