What is the content of the pre-service training for employees of brushless motor motor automatic rotor into shaft machine?

The following are the details of the pre-service training for employees of brushless motor motor automatic rotor shafting machine:

I. Equipment overview and principle

1, the basic structure of the equipment:

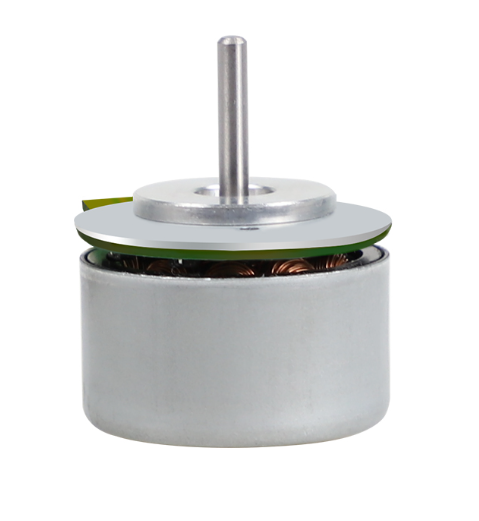

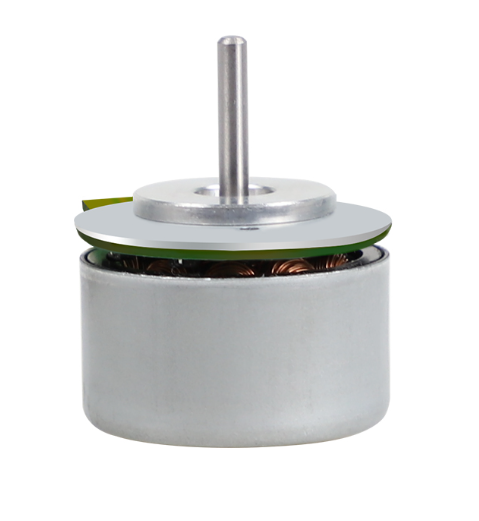

Introduce to the staff in detail the overall structure of the brushless motor motor automatic rotor into the shaft machine, including the main components such as silo, transfer mechanism, into the shaft mechanism, drive system, control unit and detection system. Use structural drawings or physical models of the equipment to help employees familiarize themselves with the location and connection relationships of each component.

Explain the function of each component, such as the storage and material conveying function of the silo, how to accurately transfer the rotor and shaft to the position of the shaft, how to complete the precise insertion of the shaft into the shaft mechanism, how to provide power for the drive system, and how to realize the automation control of the control unit, and so on.

2、Working principle explanation:

Explain the working principle of brushless motor, including the interaction of stator magnetic field and rotor magnetic field, explain how to realize the operation of brushless motor through electromagnetic induction, and how the principle is applied to the drive system of rotor shaft entry machine.

Detailed description of the workflow of the rotor shafting machine, starting from the loading of rotors and shafts, through the transfer, positioning, shafting operation, until the completion of the shafting process of discharging or transferring, so that employees can understand the logic of the entire equipment and the mechanism of synergy.

Second, operation skill training

1、Operation of power-on and power-off:

Teach employees the correct steps for powering on the machine, including turning on the main power supply, checking the power indicator of the equipment and the startup of the control unit, as well as checking the overall status of the equipment before powering on, such as whether the components are in the initial position and whether the guards are closed.

Train the staff to master the operation process of shutting down the machine, including how to stop the operation into the shaft, shut down the drive system, cut off the power supply, as well as the preparation of equipment cleaning and maintenance after shutting down the machine.

2、Daily operation process:

Explain how to put the rotor and shaft into the silo correctly, how to adjust the parameters of the silo and the operating parameters of the equipment according to different specifications of the rotor and shaft.

Instruct the employees to operate the operation panel of the equipment, including how to set the key parameters such as entry speed, entry pressure, entry position, etc., and how to use various buttons and switches on the operation panel, such as start, stop, pause and reset.

Train employees how to observe the operation status of the equipment during operation, and determine whether the equipment is working properly by observing the information on the display, the status of the indicator lights and the operation sound of the equipment, such as how to identify the normal operation sound and abnormal sound of the equipment.

3、Equipment adjustment and maintenance operation:

Teach employees how to make simple adjustments to the equipment according to the production tasks and product specifications, such as adjusting the transfer speed, the depth of entry into the shaft mechanism and the pressure, and how to use the adjustment tools that come with the equipment to make fine adjustments.

Cultivate employees' awareness of equipment maintenance, teach them how to carry out daily cleaning and simple maintenance work, such as cleaning the conveyor mechanism, cleaning the debris in the bin, adding lubricating oil and grease, as well as simple maintenance of the shaft entry tool.

Third, protection operation training

1、Protection awareness training:

Emphasize the importance of protective operations, through actual cases and videos of accidents, so that employees recognize the risks that may exist when operating the brushless motor motor automatic rotor shafting machine, such as mechanical injury (pinching, involved), electrical injury (electric shock), material splash.

Introduce the function and use of protective devices on the equipment, including guardrails, light curtains, emergency stop buttons, etc., so that employees are clear about how to use these devices to protect themselves.

2, protective operating procedures:

Detailed formulation of protective operating procedures, such as operating equipment must wear labor protective equipment, as well as in the process of equipment operation and maintenance of precautions, such as not allowed to clean or adjust the work of the equipment while running, not touch the moving parts, etc..

Train employees to respond to emergencies, such as how to use the emergency stop button, how to cut off the power supply, how to deal with material blockage and equipment failure, etc., and at the same time, conduct simulation drills for emergencies to ensure that employees are familiar with the emergency response process.

Fourth, quality control training

1、Quality standard explanation:

Make clear to employees the quality standard of rotor into the shaft, including the precision of shaft and rotor fit, the accuracy of the position of the shaft into the shaft, the concentricity of the parts after the shaft into the shaft and other quality indicators, so that employees understand the impact of its operation on product quality.

Teach employees how to carry out quality checks during operation, such as using simple measuring tools to check the quality of the product after shaft-in, identification of unqualified products and methods of treatment.

V. Troubleshooting training

1、Common fault identification:

Introduce the common failure phenomena of the equipment, such as mechanical failure (failure of transmission components, failure of the shaft-entry mechanism, silo clogging), electrical failures (motor failure, sensor failure, circuit failure) and software failures (program running errors, communication failures), etc., so that employees can learn to determine the type of failure by observing the abnormal performance of the equipment.

Teach the staff how to check the fault alarm information of the equipment, including the fault code on the operation panel, the flashing pattern of the indicator light, and how to judge the scope of the fault from the abnormal sound and operation status of the equipment.

2、Simple troubleshooting methods:

For some common simple faults, provide troubleshooting methods, such as for the silo clogging how to clean and prevent, for the conveyor belt slipping how to adjust the tensioning device, for the sensor failure how to check the line and clean the sensor head, for the software error how to try to restart the program and so on.

Cultivate the teamwork spirit of the staff, tell them how to report to the maintenance staff or superiors when they encounter unsolvable failures, accurately describe the failure phenomenon and the possible causes, in order to solve the problem as soon as possible.

Sixth, teamwork and communication training

Let employees understand their roles and responsibilities in the production team, and clarify how to collaborate with other team members in equipment operation, maintenance, quality control and troubleshooting, such as communication and collaboration with maintenance personnel, quality inspection personnel, production scheduling personnel.

Train employees on how to accurately record and report equipment operation and problems, including the filling of operation records, the submission of fault reports, and how to collaborate with other departments to jointly solve problems in the equipment and production process.

Through all of the above pre-employment training, employees will be able to gain an in-depth understanding of the Brushless Motor Motor Fully Automated Rotor Entry Machine, and acquire skills in operation, maintenance and quality control, laying a solid foundation for smooth operation and ensuring the normal operation of the equipment.

※ If you need any help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.