How to fault analyze and troubleshoot brushless motor motor manual stator slot paper machine?

Brushless motor motor manual stator slot paper machine failure analysis and troubleshooting needs to be a combination of factors to determine and deal with, the following are some common failure analysis and troubleshooting methods:

First, mechanical failure

1, paper transportation problems

Failure phenomenon: paper jamming in the conveying process, running or conveying the situation is not smooth.

Failure Analysis: It may be feeding roller wear, uneven pressure, paper placed unevenly, conveying channel is blocked by foreign objects, or drive chain, belt loose slipping.

Troubleshooting: Replace the worn paper feed roller, adjust the roller pressure to make it even; re-organize and level the placement of paper; clean up the conveyor channel of foreign objects; adjust the chain, belt tightness, if necessary, replacement.

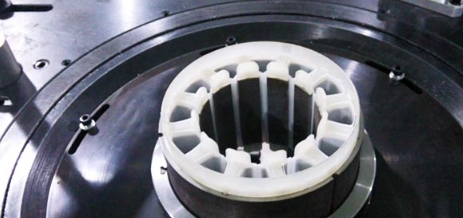

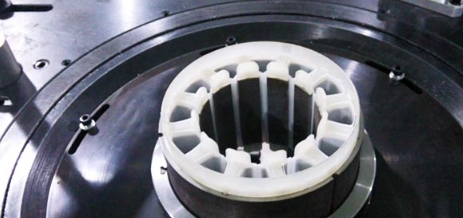

2, slot paper molding problems

Failure phenomenon: irregular shape of the slot paper, inaccurate size or poor quality of the slot paper, such as wrinkles, breaks, etc..

Failure Analysis: It may be the slot paper forming mechanism of the knife wear, loose, inaccurate positioning device, paper pressure mechanism pressure is not appropriate, or paper material is not suitable.

Troubleshooting: Replace or fasten the knives, adjust the positioning device so that it is accurately positioned; according to the material and thickness of the paper to adjust the pressure of the paper pressure mechanism; choose the right paper material and specifications.

Second, electrical failure

1、Brushless motor does not turn

Failure phenomenon: After the equipment is started, the brushless motor does not have any reaction and does not rotate.

Failure Analysis: It may be power supply failure, such as loose plug, damaged power cord, blown fuse; motor winding short circuit, disconnection or motor damage; drive failure, such as drive parameter setting errors, drive components are damaged; controller failure, such as the control signal is not output.

Elimination methods: check whether the power plug is plugged in properly, whether the power cord is broken, replace the blown fuse; use a multimeter to detect the resistance of the motor winding to determine whether the motor winding is short-circuited or broken, if there is a problem, then replace the motor; check whether the drive parameters are set correctly, use professional tools to detect whether the drive components are damaged, if they are damaged, then replace the drive; check the controller's output signals, maintenance or replacement of the controller, repair or replace.

2、Abnormal motor operation

Fault phenomenon: motor running noise, vibration, speed instability and other abnormalities.

Failure analysis: the motor bearings may be damaged, motor rotor imbalance, motor winding local short-circuit or disconnection, drive output signal instability, load is too large or uneven.

Troubleshooting methods: replace the damaged motor bearings; carry out dynamic balance test and adjustment of the motor rotor; use professional equipment to test the motor winding, repair or replace the problematic winding; check the output signal of the drive, repair or replace the drive; check the load, adjust the load to make it even and avoid overload operation.

Third, the control system failure

1、Parameter setting problems

Failure phenomenon: the equipment can not achieve the desired results when running, such as feeding speed, slot paper depth and other parameters set invalid.

Failure analysis: the operator may be mistakenly set the parameters, control system parameter storage chip failure, parameter transmission line failure.

Troubleshooting: Recheck and correctly set the parameters; replace the parameter storage chip; check the parameter transmission line, repair or replace the damaged line.

2、Abnormal control signal

Failure phenomenon: the various actions of the device is not coordinated, such as paper feeding mechanism and slotting paper forming mechanism is not synchronized, or equipment malfunction.

Failure Analysis: It may be sensor failure, such as photoelectric sensors, proximity sensors damaged or not sensitive enough, resulting in inaccurate signals; controller failure, such as logic control errors, program errors; signal transmission line interference or damage.

Elimination methods: check the working status of the sensor, clean the sensor surface, adjust the sensitivity of the sensor or replace the damaged sensor; check the controller's program and logic, necessary debugging and repair; check the signal transmission line, take anti-interference measures, such as shielding line grounding, repair or replacement of damaged lines.

※ If the above ways and means still can not solve the equipment failure, please contact Xinhui Electromechanical Equipment Co., Ltd. technical specialists through the page chat tool to seek help.