What are the contents of pre-service training for brushless motor motor automatic stator press end plate machine employees?

Pre-employment training for employees of the brushless motor motor automatic stator press end plate machine ensures that employees operate the equipment properly. The training content covers equipment knowledge, operation specification, maintenance and quality control and other aspects.

1、Basic knowledge of equipment

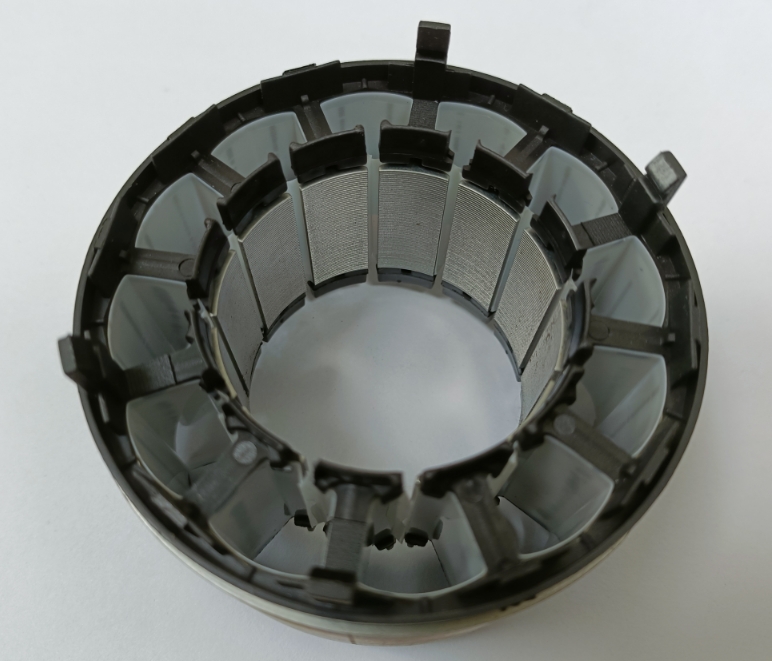

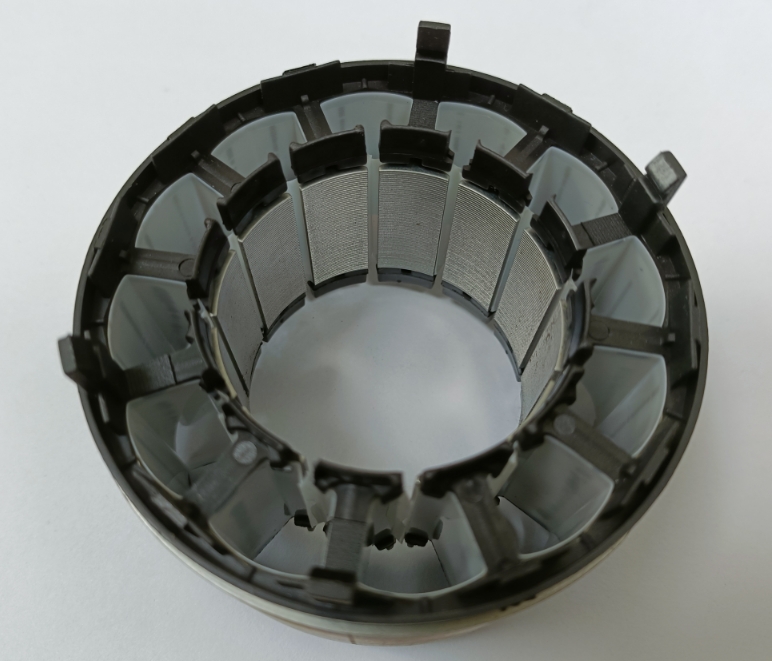

Structure and principle: Introduce in detail the overall structure of brushless motor motor automatic stator press end plate machine, including mechanical parts (such as press fitting mechanism, feeding mechanism, positioning device, etc.) and electrical parts (such as motors, controllers, sensors, etc.). Explain the function of each part and the basic principle of the equipment work, so that the employees understand how the equipment realizes the automatic stator end plate pressing and loading, and help them understand the various phenomena in the process of the equipment operation, so as to lay the foundation for the subsequent operation and troubleshooting.

Equipment parameters: introduce the key parameters of the equipment, such as the range of press-fitting force, press-fitting speed, positioning accuracy and so on. Let the employees know clearly the parameter settings applicable to different types of stators and end plates, understand the impact of parameter adjustment on product quality and productivity, and learn how to accurately set the parameters according to the production tasks.

2、Operation process training

Start-up and shutdown: Demonstrate the correct start-up sequence, including the steps of turning on the power, starting the control system and checking the status of the equipment. Emphasize the key points of checking before starting the machine, such as whether the parts are firmly connected and whether the lubrication is in place. Explain the shutdown process, including stopping the equipment first, shutting down the control system, cutting off the power supply and other operations, as well as shutting down the equipment after the organization and cleaning work.

Daily operation: Demonstrate step-by-step the normal operation process of the equipment, from placing the stator and end plate to starting the press fitting and removing the finished product after completion. Instruct employees on how to operate the control panel correctly, including parameter settings, the use of the start button, stop button, and emergency brake button. Through practical demonstrations, employees can master the operating skills and precautions for each link of feeding, positioning and press-fitting to ensure standardized and smooth operation.

Production switching: Train employees how to deal with the production switching of different models of products. Including the replacement of molds, adjust the positioning device, reset parameters and other operating steps, so that employees can quickly and accurately complete the production switching, improve production efficiency.

3、Protection knowledge training

Equipment protection: Introduce the risks in the process of equipment operation, such as mechanical moving parts may cause extrusion, collision injuries, electrical parts may lead to the risk of electric shock. Emphasize the importance of equipment protection devices, such as doors, emergency stop buttons, leakage protection devices, etc., the correct way to use, employees are strictly prohibited to open the protection device when the equipment is running.

Operation protection: Train employees on the correct operation posture and action specifications to avoid accidents caused by improper operation. For example, when placing and removing workpieces, ensure that the equipment is in a stopped state to prevent the hands from being pinched by moving parts. Explain the requirements for wearing personal protective equipment, such as caps, gloves, goggles and other correct use.

Emergency response: Develop emergency response plans for common accidents, such as how to deal with emergency shutdowns and injuries caused by equipment failure. Train employees how to identify abnormal situations, such as abnormal noise, smoke, odor, etc. of equipment, and how to use the emergency stop button correctly in case of emergency, on-site first aid. Regularly organize emergency drills, so that employees are familiar with the emergency handling process and improve their ability to deal with emergencies.

4、Quality control training

Quality standard: make clear to the employees the quality standard of the products, including the key indexes such as flatness, perpendicularity and depth of end plate pressing. Through sample display, picture comparison, etc., let employees intuitively understand the difference between qualified products and unqualified products, so that they have a clear quality goal in the operation process.

Process Inspection: Train employees how to carry out quality inspection during the production process, such as using gauges (calipers, micrometers, etc.) to measure product dimensions, checking the appearance quality of the end plate press-fitting, etc. Teach employees how to identify common quality problems, such as pressure deviation, indentation, looseness, etc., and analyze the causes. Let the staff master the measures to be taken when quality problems are found, such as timely adjustment of equipment parameters, suspension of production for investigation, etc., to ensure that product quality meets the standards.

5、Equipment maintenance training

Daily maintenance: explain the importance of daily maintenance of equipment and specific content, including equipment cleaning, lubrication, parts fastening and other operations. Instruct the staff how to clean the equipment at the end of each day's work, remove the dust, debris and oil on the surface. Introduce the location and lubrication interval of each lubrication point of the equipment, and teach employees to add lubricating oil or grease correctly. Emphasize the regular inspection of equipment components connected to whether it is firm, if any loosening in time to tighten, in order to ensure the normal operation of the equipment.

Judgment and treatment of common failures: train employees to identify common equipment failures, such as motor does not turn, unstable pressure, sensor failure. Through actual case studies, explain the possible causes of failure and the corresponding treatment. Employees are made aware of how to properly report equipment malfunctions, as well as temporary measures that can be taken before the arrival of professional maintenance personnel to avoid the expansion of malfunctions due to improper operation.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. via the page chat tool for assistance.