What are the spare parts required for a manual stator slotting machine for brushless motor motors and how should I set up a guaranteed stock?

The spare parts and guarantee stock of brushless motor motor manual stator slot paper machine are set as follows:

I. Types of spare parts

1、Electrical

Brushless motor: as the core power components, the motor may fail due to long-term use, overload and other reasons, spare motor is needed for timely replacement to ensure the normal operation of the equipment.

Controller: Control the operation of brushless motor, including speed control, steering control, etc.. The electronic components of the controller may be damaged, resulting in the motor can not work properly, so the need for spare controller.

Sensors: such as sensors used to detect the position of the paper, motor speed, etc., in the long-term use of precision may be reduced, damaged and other issues, affecting the normal operation of the equipment, the need to prepare the appropriate spare parts.

Wire and cable: equipment wire and cable may be due to wear and tear, aging and other reasons such as insulation damage, short-circuit and other issues, the need for spare wire and cable of different specifications.

2、Mechanical

Gears: In the transmission process, the gears may be worn, broken teeth, etc., affecting the transmission accuracy and stability of the equipment, you need to prepare different specifications and modulus of the gears as spare parts.

Chain and sprocket: Chain may elongate and wear out after a long time operation, and sprocket may also wear out, so we need to prepare spare chain and sprocket.

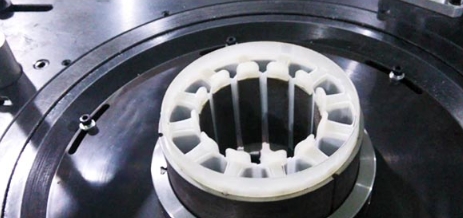

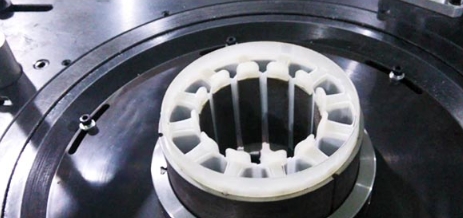

Bearings: Bearings are the key components to support the rotating parts, and are prone to failure due to wear, poor lubrication, etc. Various types of bearings are required.

Belt and pulley: the belt may slip or break during transmission, and the pulley may wear out, so we need to prepare spare belts and pulleys.

Screws and nuts: equipment on the screws and nuts in the long-term vibration and other effects may be loose, lost, need to prepare a variety of specifications of the screws and nuts.

3、Wear parts category

Knives: Knives used for cutting paper will gradually wear out during use and need to be replaced regularly, different types and specifications of knives should be prepared.

Paper conveying roller: roller in the process of conveying paper will be friction with the paper, resulting in surface abrasion, affecting the accuracy and stability of paper conveying, the need for spare conveying roller.

Seals: such as seals, gaskets, etc., used to prevent the leakage of lubricating oil, coolant, etc., after long-term use may be aging, damage, the need to prepare the appropriate seals.

Second, to protect the inventory setup method

1、Historical data analysis

Collect the past maintenance records and operational data of the equipment, analyze the replacement frequency and usage of each spare part. For example, through the analysis of the past year found that a certain type of bearings need to be replaced every 3 months on average, each time the replacement of 2, then you can be based on this data to initially determine the protection of the bearing stock.

2, the supplier delivery date

Understand the delivery period of the spare parts supplier, for the longer delivery period of spare parts, the need to set a higher guarantee stock. For example, a special specification of the gear supplier's delivery period of 2 weeks, in order to prevent damage to the equipment in these 2 weeks due to gear downtime, it is necessary to set up a certain amount of security stock according to the use of equipment and the importance of the situation.

Operational condition of equipment

If the equipment is in good operating condition, the failure rate is low, you can appropriately reduce the guaranteed stock; if the equipment running time is long, aging, or recently found that there are some potential failures of the equipment, you need to increase the guaranteed stock.

3、Production plan

Combined with the production plan to set the guaranteed inventory. If the future period of heavy production tasks, equipment used more frequently, you need to increase the spare parts to ensure that the equipment in the production process will not be due to a lack of spare parts and downtime.

4、Cost factors

Consider the procurement cost of spare parts, storage costs and other factors. For higher procurement costs, storage costs are also higher for spare parts, under the premise of ensuring the normal operation of the equipment, try to reduce the guaranteed inventory; for lower procurement costs, easy to store spare parts, you can appropriately increase the guaranteed inventory.

5、Regular inventory and adjustment

Establish a regular inventory system, monthly or quarterly inventory of spare parts inventory, timely understanding of the inventory quantity and use. According to the actual use and equipment operating conditions, the guaranteed inventory is adjusted to ensure that the guaranteed inventory is always at a reasonable level.

※ If you need help, please contact the technical specialist of Xinhui Electromechanical Equipment Co., Ltd. through the page chat tool for assistance.