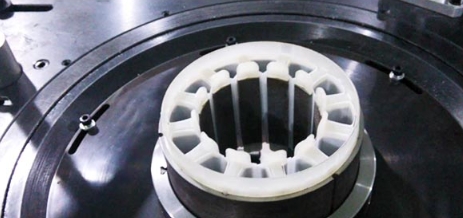

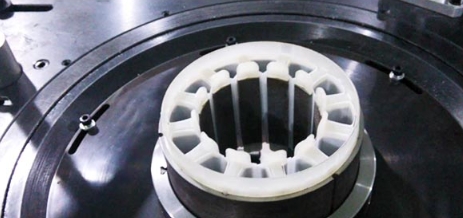

How should the brushless motor motor manual stator slot paper machine be maintained?

Brushless motor motor manual stator slot paper machine maintenance mainly involves mechanical components, electrical systems, working environment and other aspects, the following are the specific content:

First, mechanical parts maintenance

1、Cleaning

Regularly (at least once a week) use a clean soft cloth to wipe the surface of the equipment, clear away dust, paper and oil and other debris, to prevent it from entering the internal equipment to affect normal operation.

For parts that are not easy to wipe, such as slotted paper machine gaps, corners, etc., you can use a compressed air gun to blow to ensure that no debris remains.

2、Lubrication

In accordance with the requirements of the equipment manual, regularly add appropriate lubricating oil or grease to the transmission components, such as gears, chains, bearings, etc.. Generally speaking, every 200 - 300 hours of operation or monthly lubrication maintenance should be carried out.

Pay attention to check the quality and level of lubricating oil or grease, if you find that the oil quality is poor or the level is too low, it should be replaced or supplemented in time.

3、Fastening

Frequently check whether the connecting parts of the equipment, such as screws, nuts, etc. are loose, especially in the process of vibration generated by the operation of the equipment, such as the motor mounting base, the connection parts of the transmission mechanism.

At least once a month for all the fastening check, the loose screws, nuts to tighten, to prevent damage to parts due to loosening or equipment failure.

Second, the electrical system maintenance

1、Motor Maintenance

Regularly check the appearance of the brushless motor to see if there are abnormal phenomena such as overheating, discoloration, odor, etc. If so, it should be shut down in time for inspection.

Check whether the connecting wires of the motor are loose or broken, and make sure the connection is reliable to prevent electric sparks or motor failure due to poor contact. Quarterly insulation resistance meter can be used to measure the insulation resistance of the motor to ensure good insulation performance.

2、Maintenance of controller

Keep the controller clean to prevent dust and moisture from entering inside the controller and affecting the performance of electronic components. Dry compressed air can be used regularly to blow the dust inside the controller.

Check whether the controller's cooling fan is running normally, to ensure that the controller works within the normal temperature range. If the fan is found to be faulty, it should be replaced in a timely manner.

3、Sensor maintenance

Check whether the installation position of the sensor is correct, whether there is any looseness or displacement phenomenon, to ensure that the sensor can accurately detect the operating status of the equipment.

Clean the sensor's sensing surface to prevent dust, oil and other pollutants affecting the sensor's detection accuracy. For photoelectric sensors, you also need to check whether the light source is normal, if there is any problem timely replacement.

Third, the working environment maintenance

1, temperature and humidity

Try to slot the paper machine placed in the temperature and humidity in a relatively stable environment, the temperature should be controlled at 15 ℃ - 35 ℃, humidity between 40% - 60%.

Avoid equipment exposed to high temperatures, humidity or corrosive gases in the environment, such as can not be avoided, should take appropriate protective measures, such as the installation of air conditioning, ventilation equipment.

2、Cleaning and debris cleanup

Keep the environment around the equipment clean, clean up the confetti on the ground in a timely manner, debris, etc., to prevent it from entering the equipment or affecting the operator.

Regular cleaning of the work area where the equipment is located, including cleaning up walls, ceilings, dust, etc., to create a good working environment for the equipment.

Fourth, regular inspection and testing

1、Functional test

Weekly or biweekly functional test of the equipment, check the slot paper machine function is normal, such as whether the paper feed is smooth, slot paper depth is in line with the requirements, whether the motor speed is stable and so on.

Some key performance indicators of the equipment for regular testing, such as motor torque, power, etc., to ensure that the equipment is in excellent working condition.

2、All inspection

Monthly or quarterly inspection of all equipment, including mechanical components, electrical systems, software systems and other aspects of the inspection, the problems found in a timely manner to repair and deal with.

Record the operation of equipment, maintenance and repair of faults, the establishment of equipment files, so as to facilitate the performance of the equipment and maintenance status of tracking and analysis.

If you still can't solve the equipment failure by the above ways and means, please contact Xinhui electromechanical technical specialists through the page chat tool to seek help.